Developing an Unusual Two strokecycle Engine

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

IN our issue of April 8th, 1930, we described the general working principles of the Rodger engine, operating on the two-stroke cycle,

Before going farther it will be well to recapitulate the leading features of the power unit. The flat-topped pistou works in a ported sleeve ; the latter is driven by an eccentric on the crankshaft and has a plain reciprocating motion. The sleeve lags behind the piston by 60 degrees and the cycle allows compression to take place during 90 degrees of crank travel, but expansion occurs during the unusually long period of 160 degrees ; this gives more economical use of the fuel and a cooler exhaust. Owing to the short period available for induction of the fresh ,charge crankcase compression is notused ; mixture is delivered to the cylinder by a blower which draws its supply from the carburetter.

We recently inspected the first engine and saw it running on the bench. A few turns of the crankshaft were sufficient to start the motor and it ran steadily at about 600 r.p.m. It was not advisable to exceed this rate for two reasons ; first, the 6-in.-diameter blower was or too great a capacity for -the -cylinder volume, 3 ins, bore and 5 ins, stroke; secondly,. the exhaust was open and the works near to private houses.

There was no blower noise and the exhaust was much more silent 'than that of ordinary two-stroke-cycle engines without silencers. The extent of the expansion of the gases can be gauged from the fact that we were able to hold our hands close to the open exhaust ports while the engine was running; 'the gas leaving the ports was .clear and free from oily vapour. The compression stroke occupies 2i ins. of piston stroke, but expansion occurs during 4 ins. of .stroke.

The inventor demonstrated the lightness of,the engine by carrying it unaided across the workshop ; aluminium is used for every part possible, whilst the two connecting rods— for the piston and sleeve—are both in duralumin. The cylinder barrel is air-cooled, but the head is water-cooled, Further development is now proceeding and Mr. Robert Rodger will gladly furnish further details to those ,who may be interested in the design. His address is Almond Park, Blackburn, West Lothian, Scotland.

We have seen plans for the use of this engine as a compression-ignition unit running on petrol, the . fuel being injected directly into the combustion chamber and metered by a patented device of Mr. Rodger's invention

THE municipal authorities of Wolverhampton have had a long experience of the operation of buses, the corporation having started its 'first service with vehicles of this type as long ago as. 1905. At the time when our analysis of municipal bus services was published in March last it was running a beet of 140 vehicles, equally divided between petrol buses and trolley-buses. Tramcars were abandoned over two " years ago in the town, and an outstanding feature of the municipal passengertransport system has been the success of the trolley-bus which, in 'the opinion of Mr. C. Owen Silvers, A.M.I.E.E., M.Inst.T., is superior to the petrol bus on services entailing frequent stops. In fact the authorities have converted certain routes from motorbus to trolleybus operation.

So far as the latter type of vehicle is concerned Wolverhampton Corpora tion was the first •undertaking to put into use a double-saloon six-Wheeler, this being in 1926, and since that time it has placed orders for a total of .5O Guy double-deckers of this type, the first 42 being for chassis only, whilst the others were built throughout in the works of Guy Motors, Ltd., Fallings P a r k, Wolverhampton. They are large-capacity vehicles seating 61 people. The chassis, of course, are fitted with the system of regenerative braking unique • to Guy trolleybuses.

In the year ended 111areh 21st, 1930, the Wolverhampton trolley-bus undertaking made a profit of over £75,000, which was cousiderabis greater than the next largest profit made in that year on any other trolleybus undertaking in England.

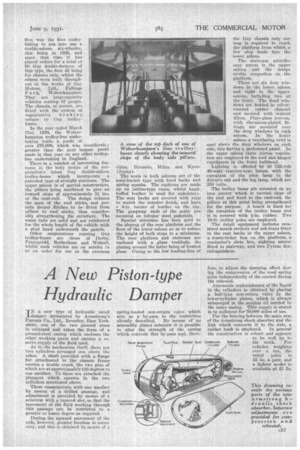

There is a number of interesting features in the body design of the corporation's • latest Guy double-saloon trolley-buses which incorporate a Patented type of straight staircase. The upper saloon is of special construction, the pillars being machined to give an inward slope of approximately 3A

at the cant-rail. The design reduces the span of the roof sticks, and permits deeper flitches to be -fitted from pillars to roof sticks, thus considerably strengthening the structure. The waist rails are solid and Etre reinforced for the whole length of the vehicle with a steel band underneath the panels.

Other corporations running Guy trolley-buses are those of Derby, Pontypridd, Rotherham and Walsall, whilst such vehicles are on service in or on order for use in the overseas cities, Brussels, Milan and Kyoto (Japan).

The seats in both saloons are of the serni-bucket type . with fixed hacks and spring squabs. The cushions are made up on lattice-type cases, whilst handbuffed leather is used for upholstery. The seat backs are covered with rePP to match the interior finish, and have a 4-in, border of leather on the top. The gangway ends of the seats are mounted on tubular steel pedestals.

Special attention has been paid to the sloping of the rear platform and the floor of the lower saloon so as to reduce the height of both steps to a minimum. The rear platform and staircase are enclosed with a glass vestibule, the glazing around the latter being of frosted glass. Owing to the low loading-line of

the Guy chassis only one step is required to reach the platform from Which a low step leads into the lower saloon.

The staircase priwides easy aedess to the upper saloon and the design aVoids congestion on the platform.

There are six drop windows in the lower, saloon and eight in the upper saloon, including two at the front. The fixed win dows are bedded in velvet covered -rubber channel and secured •-with walnut fillets. Plate-glass louvres,

with chromium-plated fittings, are mounted over the drop windows-in each

saloon, In the jonier • saloon a ventilating cowl is

used above the drop windows on each side, this hating ft perforated panel. In the upper saloon -three Airviie ventilatort are employed in the roof and hinged ventilators in the front bulkhead.

Lighting • is effected by 30 125-volt 40-watt traction-type lamps, with the exception of the pilot lamp in the driver's cab and the fog lamp, which are 250 volts.

The trolley bases are mounted on an iron gantry which is carried clear of the roof and fixed to the cant-rail, the pillars at this point being strengthened for the purpose. A board is fixed for the reception of the trolley bases and it is covered with rubber. Two 18-ft. trolley poles are employed.

The detail equipment includes combined match strikers and ash-trays fitted

to the seat -backs in the. upper saloon, a waste-ticket box on the platform, a conductor's slate box, sighting mirror fitted to stairway, and two Pyrene fireextinguishers.