JAPAN: COUNTRY OF C TRASTS

Page 58

Page 59

Page 60

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

BY ALAN HAVARD M INSTT Japanese manufacturers could do a 'camera' on us PART I OF A NEW SERIES

IVE me, in about half a page (small memo size), the main impression from your Japanese visit ", said my managing director. It proved to be a salutary, but difficult, task. Whilst managing directors can enforce such requests, I do not propose to let my readers away so lightly. Not, I would point out, from any vengeful motive but because the distillation of all useful information collected during three weeks of furious activity—the documents and photographs alone weighed some 35 lb.— is necessarily a lengthy process. A process, I strongly suspect, which my ni.d. fully appreciated; hence his short-cut.

In fact, I came back from Japan with a series of impressions—some strong, some more tenuous—on a variety of subjects. During the course of the next four or

five weeks I shall discuss my impressions in some detail. Inevitably they will centre largely around the vehicles produced by the Japanese, as my primary intention was to gather information about them and to drive some of them. It was also possible to visit some operators (one C-licensee, one 56,000-vehicle haulage fleet, one touring coach operator and one high-speed bus operator) and these I shall also write about.

Perhaps the most significant question is: " Will Japanese commercial vehicles be on sale in the United Kingdom in the next few years?" The answer must be that, on the evidence 1 came across, this seems unlikely (as a general statement) within five years. Well before that time, however, they will be available on the Continent; I was told that one 4-tonner will be shown at next year's Amsterdam Show. My personal view is that the initial assault may well come on an unlikely front—that of the 16/20-seater coach.

There is little doubt in my mind that Japanese commercial vehicle makers, in general, would like to sell in Europe. They do, however, realize the commercial and technical problems involved—and it could be the latter, as much as the sales questions, which hold them back.

As a pure generalization, 1 would say that my basic impression of Japan was of a range of competently designed, well-produced vehicles which. were none the less unexciting. There were, however, outstanding exceptions, notable amongst which must be counted Toyo Kogyo, of Hiroshima (whose vehicles are produced under the Mazda nameplate). Toyo Kogyo are very advanced. indeed, down the path of rotary engines. They produce the NSU Wankel engine under licence and, in my view, could possibly license some of their ideas on the subject back to NSU! More about them later; suffice it now to whet your appetite and

say they have plans to install a four-rotor unit in trucks.

Inevitably, I suppose, there are a number of such highlights in any trip. I came across another at the Honda firm—whose prime concern is certainly not commercial vehicles! How do you fancy an 8 cwt. pick-up with a twin overhead-camshaft horizontal engine and four carburetters? You can buy it from Honda.

Admittedly, such a vehicle is highly specialized and would probably never sell outside Japan; it was originally developed as a private car design because taxation heavily favoured engines of 360 c.c. or lower capacity. But its existence proves the point I wanted to make, that individual aspects of Japanese design are very advanced. This leads me to make the next point, that I came away strongly impressed that they could, if necessary, make tremendous technical strides in a very short time. Just out of interest, I briefly compared the Honda (which comes in two versions) with our BMC Minis, The Honda T360 produces 30 b.h.p. at 7,500 r.p.m. from an engine of 49 mm. bore and —47 mm. stroke and capacity of 354 c.c. and has a maximum torque of 19-5 lb. ft, at 6,000 r.p.m. Its claimed maximum speed is 62 m.p.h., the dry weight is 1,345 lb. and recommended payload is. 770 lb. Overall length is 9 ft. 10 in. Its big brother, the T500, gives 38 b.h.p. at 7,500 r.p.m. from a slightly bigger engine (54 mm. bore, 56 mm. stroke and 531 c.c. capacity). Peak torque is 31.1 lb. ft. at 4,500-r.p.m., top speed is claimed as 65 m.p.h., dry weight is 1,411 lb. and payload 882 lb. In contrast, the 5 cwt. Mini produces 34 b.h.p. al 5,500 r.p.m. from a 848 c.c. engine (63 trim bore, 68 mm. stroke), with maximum torque or 441b. ft. at 2,900 r.p.m. Top speed (as road-tested by The Commercial Motor) was 60 m.p.h. Kerb weight of our road-test Mini was 1,300 lb. and its payload is 560 lb.

Two ingenious designs—two radically different approaches!

Enough of particular vehicles for a moment; I shall devote at least two articles to reviewing the manufacturing industry and its products. What of the Japanese scene?

Basically speaking, Japanese heavy goods vehicles tend to be solidly built, when compared with equivalent European vehicles, with consequently high unladen weight. They have diesel engines pushing out high brake horse powers, but generally their torque is lower. On average however, they run at about 12 b.h.p./ton—a very high power-to-weight ratio. Two of the most notable general features are good turning circles and low-geared steering. All these trends are directly attributable to a road system which (outside main centres) is still substantially based on narrow, unpaved roads. By the same token, very hefty leaf springs are commonplace! Japan is also a mountainous country, so that vehicle design has not only to account for narrow, dirt roads with uneven surfaces but also for steep gradients and winding mountain roads.

These same conditions have also resulted in a range of predominantly rear-enginecl, single-deck buses on which air suspension has in some cases been common since as early as 1951. On average they carry about 45 seated and 38 standing passengers, but in peak moments might well carry 90 or more passengers. Average engine size is around 150/160 b.h.p. gross.

It is well to have this picture of Japanese roads in mind because it does explain a lot of what one initially tends to regard as slightly outdated design. Japanese vehicles have to be built ruggedly for home conditions. This is now producing a tremendous export bonus because, even in such traditional British markets as Australia, the robust specifications of Japanese vehicles are capturing some of our export markets. They are selling well throughout South East Asia and in South Africa.

A popular misconception is to regard Japanese haulage as being largely dominated by three-wheelers. There are , still a lot around, but they are now being overtaken by

four-wheeled, 1, 14 and 2-tonners. The three-wheelers remain, however, a popular local-delivery vehicle and are a major export class of vehicle to some Asian countries. Having driven one (a Mazda 2-tonner),I can also state that they are, in fact, very powerful goods vehicles and not in any sense toys—with, of course, fantastically small turning circles. The one 1 drove had an 81 b.h.p. engine and turned inside its own length . . . more about it later.

Apart from Russia, I can think of no other country with a major automotive-producer industry, which is like Japan, where private cars do not account for the majority of the total annual production. In Japan, cars still only account for about 30 per cent of annual production. In America and Europe cars represent about 80 per cent of the total four-wheeled vehicle production.

The Japanese industry has a relatively short history. Hardly any cars were produced in pre-war days, the emphasis being on building trucks (for military use) and buses. After the war, production was severely restricted and the industry only really started in 1952, when Japan regained its sovereignty. In the subsequent 10 years, between 1953 and 1963, truck output rose to 24 times its initial level. The following table illustrates my point (note how rapidly 3-wheeler production has tailed off since 1960):—

COMMERCIAL VEHICLE PRODUCTION Trucks Buses 3-wheelers 1949 . . 25,560 2,070 26,727 1959 .. 177,485 6,731 158,042 1960 .. 308,020 8,437 278.047 1961 . . 553,390 10,981 224,595 1962 .. 710,716 11,206 144,167 1963 . 862,781 12,920 117,190

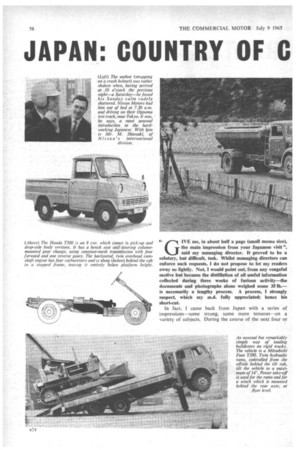

With the emergence, particularly in the past five years, of a comparatively affluent and considerably more enfranchized society, demand has built up fantastically for pick-up trucks in the ranges up to 2-tons payload capacity. These all (I think without exception) have three-man bench seats in the cabs and many are actually based on private-car designs. The average Japanese can therefore combine most of the advantages of owning a car with the usefulness of his own truck (and lower cost). In fact, an exactly identical situation with the one existing in this country with small vans.

At the moment the Japanese automotive industry is a series of individual units; each is in itself very efficient, but naturally there must be tremendous excess capacity. Everymanufacturer, for instance, has huge press and machine shops and its own foundry and bodybuilding plant. Neatly all gave the impression of not working at full speed. This potentially dangerous situation (for a country which has to sell in world markets) has obviously been recognized by the Ministry of International Trade and Industry. This Ministry (known to everyone as " Miti virtually rules the automotive industry—the banks obviously Control the industry!

" Miti "is pressing very hard indeed for mergers. One occurred about 18 months ago when the various Mitsubishi

companies were all consolidated under one roof. While I was in Japan, it was announced that Nissan and Prince (respectively numbers two and eight in importance) would merge by the end of 1966. This would place them roughly on a level with Toyota, the largest Japanese producer. Also while I was there Toyota and Nissan announced "agreement in principle to eliminate excessive competition ". People 1 spoke to'were inclined to think that, in view of the intense rivalry between the two concerns, little would be seen in practice of this; it was generally regarded as a "political' move.

The president of Fuji Heavy Industries (they produce about 60,000 vehicles a year) saw fit to announce that his company would not join the Nissan/Prince group. But, in response to long-standing pressure from " Miti", Fuji would refrain from head-on competition with Nissan models.. The powerful Japan Industrial Bank has interests in both Nissan and Fuji.

Several times I heard Hino Motors' name bandied about as another candidate, but they categorically denied any merger intent when J asked them (I would, of course, have been vastly surprised at any other answer).

All this, remember, took place in the three weeks I was there. How much more is likely to happen in the next year or two?

Some idea of the relative size of the producers can be gained from this table of• four-wheel vehicle production, by maker's name (bear in mind that Hino, lsuzu and Mitsubishi are predominantly "heavy vehicle producers):

1962 Total Cars Total 1963 Cars Toyota .. 230,350 74,515 318,495 128.841 Nissan .. 212,258 89,003 268,315 118,538 Toyo Kogyo 162,381 41,822 192,511 53,080 "Mitsubishi 71,963 8,196 96,491 15,882 Isuzu 66,647 15,367 79,457 22,495 Daihatsu 68,540

100,882 516 Prince .. 41,592 12,944 53,756 29,280 Fuji .. 36;913 12,442 60,177 19,030 Hino 33,247 11,730 38,493 16,750 Suzuki . . . 13,918 2,565 40,287 2,3 *This figure obtained by adding together figures of separdre com panies merged last year.

Since 1962 the Japanese have been second only to the USA in annual total vehicle production. It is noticeable. however, that in Japan there are virtually no articulated vehicles except machinery-carrying low-loaders, and the predominance of vehicles in the payload range: up to 3 tons is very marked. The majority of their " heavy" vehicles are 7and 8-tonners, although there is now a considerable move towards 10-tonners. Forward-control designs, with tilt cabs, are now coming into use in fastincreasing numbers.

The predominance of diesel engines, even in small vehicles, is explained first by the pre-war military preference for such power units and latterly by the preferential tax on derv, when compared with petrol.

The biggest lorry produced in Japan is the Moo 114tonner. This is so because the maximum gross weight for a goods vehicle is normally 20 tons. The box dimensions in Japan are as follows: length 12 m. (39 ft. 6 in.): width 2-5 m. (8 ft. 21 in.); height 3.5 tn. (11 ft. 6 in.); axle load 10 tons; maximum turning circle 24m. (79 ft.); stopping distance from 50 k.p.h. (31 m.p.h.) 22 m. (72 ft. 4 in.). In

view of our own requirement for a minimum efficiency of 50 per cent for plated vehicles, this Japanese figure is interesting in that it represents approximately a 45 per cent braking efficiency.

The Japanese Ministry of Transportation also regulates power-to-weight ratios and tyre loadings. In practice the maximum gross weight of a two-axle goods vehicle is about 14-7 tons, at which weight the payload would be roughly 8-5 tons. Three axles are used above these weights, only one twin-steer model (the Hino I mentioned) being produced; the rest have a trailing rear axle usually with single tyres.

Vehicles of a bigger g.v.w. than 20 tons are classified as "heavy duty models" and their use is restricted by the Ministry.

There are also regulations concerning noise and smoke, but these are not yet being actively enforced. The Tokyo police, I was told, have smoke meters but do not use them. A noise meter was recently displayed prominently in Tokyo so that the public could read levels for themselves. (As an aside, I would add that I saw practically no evidence of exhaust smoke and, because of the general absence of tall buildings even in cities like Tokyo, noise seemed no problem despite congested traffic.) Since last year, the Japanese have had open their first motorway. It is a perfectly good two-lane dual carriageway to European standard (the service areas are of a much higher standard-particularly catering). They now intend to go ahead rapidly-and in Japan the word means what it says, an elevated expressway being blasted through Tokyo in something like a year-with a network of these roads.

At the moment a general speed limit on all commercial vehicles, goods and passenger, of 50 m.p.h., is imposed on the motorway, but this will be raised progressively. It is giving rise to demands for more refined designs, higher speeds and bigger payloads. Already the Japanese manufacturers are responding and one example is in the new breed of "highway buses" which are now available. I rode in two on the motorway, a Hino 40-seater (no standing on motorways) of quite high standards of comfort powered by a naturally-aspirated, rear-mounted, flattwelve diesel engine producing more than 300 b.h.p. and a similar-sized Fuso (the name Mitsubishi heavies are produced under) with a turbocharged 290 b.h.p. V8 mounted at the rear. I drove one of the Fusos, fully loaded, and will write later in detail about it. Suffice it now to say that it was one of the most exhilarating drives

have had anywhere.