Part of the New "Shell" Fleet at Fulham.

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

The problem of the supply of motor spirit is, of course, one of the most vital connected with the eommercial-motor industry. All petrol-propelled motor vehicles depend entirely for their regular running upon the adequate supply of the necessary spirit, and if the stock runs short at any one of the hundreds of depots, it is essential that fresh supplies be obtained at once. Hew to continue to cope with this ever-increasing problem has for some time occupied the minds of the British Petroleum Co., Ltd.

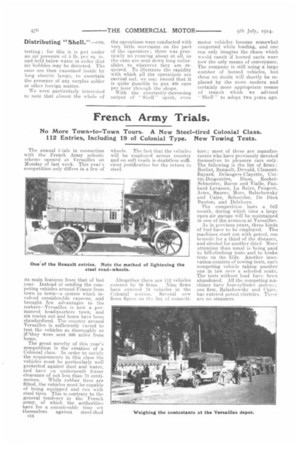

The conveyance of large quariti

ties of petrol by horsed van and by rail has not proved invariably satisfactory in the past, but the company is now working a fleet of over 150 motor tank wagons and other types of petrol motor vehicles. One of our illustrations on this page shows a fleet or " Shell " motor tank wagons built by Leyland Motors, Ltd., for dealing in bulk with the supplies of spirit which are brought to Shell Wharf, Fulham, by river. The other picture shows part of the composite fleet of motor vehicles, each of which can carry 1000 two-gallon cans of " Shell " spirit.

In addition to the company's own large fleet of motor vehicles, dozens of others belonging to various outside contractors are always being loaded and unloaded at the wharf.

: The facilities for the dispatch of the spirit are very good ; it is first pumped front the :barges into a number of very large it tanks, and from these it is carried, by overhead pipes, to distributing valves, the latter being provided with armoured flexible-hose. For filling the cans there are about GO different distributors, which measure out the spirit in exact quantity. Periodically, cans are taken from the batches received from the fillers and carefully weighed, to check the quantity of spirit. We were informed, dining our visit.•Lha.t a gang of five lads can easily fill 300 cans per hour. The actual filling is perhaps the simplest work of all, for, previously to this, they have to go through a large number of operations, which inelade the emptying of any remaining spirit out of the returned cans, and their testing under air pressure to ascertain if there are any leaks.

Dented cans are put under an air pressure of 20 lb. to the sq. in., which blows them out into almost perfect condition. They are then put through caustic baths to re

move all the old paint, and sent to the paint shop to be renovated. The testing does not only include the outside of the can, hut special lamps are provided by which almost the whole of the interior can be viewed for the preseciee of dirt or rase The total number of cans filled per day varies between 15,000 and '20,000.

The wonderful way in which motor vehicles can be manceuvred in comparatively-congested areas was well shown by the manner in which the vehicles were drawn up, for the purpose of photographing. On the occasion of our visit it at first seemed that it would be impossible

to separate the fleet sufficiently to get all the four tank wagons, which were then at the wharf, together, as the time at which the photographs were taken was the busiest of the day, when vehicles from all over London were running to the wharf to be loaded up.

The condition of the " Shell fleet of vehicles is praiseworthy, the paint-work is scrupulously elean, and all the fittings are polished up to the highest degree, the drivers apparently taking great personal interest in their machines. It, of course, has to be remembered that the fleet is as yet a new one. The vehicles form a striking advertisement for " Shell " spirit, as no doubt ninny of our readers will have observed.

While at the wharf we were conducted over the can factory, and were interested in the large number of operations required for the manufacture of a petrol can. Altogether, each can goes through 16 distinct processes. A sheet of tinplate is first cut into two blanks in a large press. Next to this press is another, which stamps the blanks with the necessary lettering, and also the grooves for the seams. A third tool rolls the body plate square, and a fourth presses the seams together, and thus forms arm ,open-ended oblong can-length. Other machines flange the ends of this unit to receive the top and bottom pieces, which are afterwards squeezed on.

After going through several other minor operations, the haltfinished cans are sent up by elevators to the soldering shop, where they are first put through a bath of acid flux, and then into one of molten solder. The filling faucets are heated on a plate, dipped into flux and put in position over the flanged hole in the top of the can. A stick of solder is then passed round the bottom of the faucet and melted.

After the soldering of the handles, the can is ready for testing ; for this it is put under an air pressure of 5 lb. per sq. in. and held below water in order that air .bubbles may be detected. The cans are then examined inside by long electric lamps, to ascertain the presence of any surplus solder or other foreign matter.

We were particularly interested to note that almost the vhole of

the operations were conducted with very hale movement on the part of the operators ; there was practically no running about at all, as the cans are sent down long rollerslides to wherever they are required. To illustrate the rapidity with which all the operations are carried out, we may record that it is quite possible to put 400 cans per hour through the shops. With the constantly-increasing output of " Shell " spirit, oven

motor vehicles become somewhat congested while loading, and one can only imagine the chaos which would result if horsed carts were now the only means of conveyance. The company is still using a large number of horsed vehicles, but these no doubt will shortly be replaced by the more modern and certainly more appropriate means of transit which we advised Shell " to adopt two years ago.