THE CONSTRUCTION OF BUS BODIES.

Page 23

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

The Simplest and Best Designs and Methods of Construction for Both Single-deckers and Double-deckers.

As motor bodywork is closely allied to a modern, branch of engineering, the view is often expressed that it is time the wooden body, admittedly often an example of fine craftsmanship, was dispensed with and gave place to a scientific metal structure. This, it is claimed, would be designed from calculated strains and stresses, made of material of known strength and behaviour, weight would be reduced to a minimum and standardization would be facilitated.

For private use the metal body has been built at various times, sometimes singly or in fairly large batches, whilst just now it_is again coming to the fore owing to the activities of a very large concern in the United States which specializes in this form of construction. But, except for the pioneer work, such as the Hewer bodies of 1913 and those made under the May row patents--and, of course,the everyday building of Steel tipping bodies, tank wagons and so on— there has not been much encouragement given to metal commercial bodywork, especially that designed for passenger use.

It is alleged that it is expensive to fit up and finish the metal structure. This is not so if the parts be properly designed in the first place, so that fastening them together and the attachment of fittings, finishers and upholstery are made easy, The lack of attractive and pleasing qualities can hardly be substantiated, Lecause there is more scope in this direction with metal than with wood. Again, the need for the elimination of noise, especially drumming, is put forward as a deterring factor.

It is admitted that a body built entirely of metal is naturally more resonant than a wooden one or one of wood and metal ; but not even the keenest advocate of metal .,vould insist that proper insulation, by the use of felt, rubber and wood and other materials, should not receive due attention. The main point is that metal should be used more freely for framework. It is already used extensively for panels.

Standardization of Payts..

A disadvantage of the metal framework is that, if it Is to be well designed and produced economically, it must be made in comparatively large quantities. There is plenty of scope for such activities in producing standard private bodywork, but, with bus work the firms which are likely to want identical bodies in 50s and 100s are few and far between. If this state of affairs limits the possible demand for complete standardized bodies, it should be worth while considering the production of standardized parts, so that individual requirements could be met and the single body built by improved methods at no greater expense than at present obtains.

Design One of Repetition.

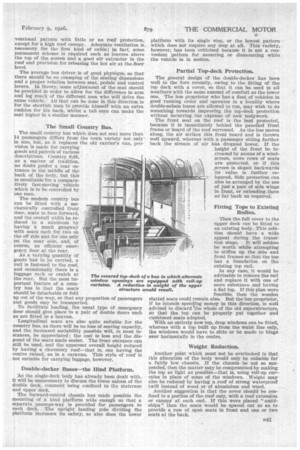

Looking at the matter broadly, a great deal of bus design consists of taking sets of pillars, hoopsticks and other items and varying their spacing apart according to the length of body, seating capacity required and the position of the hind wheels. The unit of the framework may be regarded as a continuous, transverse member consisting of a pair of side pillars connected at their lower ends by a cross bottom bar or nearer, and at their upper ends by a hoopstick. These units 6re held rigidly, and at the right distance apart, by the cant rails at the top, the outside waist rails and inside garnish rails at the middle, and by the bottom sides at the floor level.

If it be inexpedient to make up these transverse units, then the side pillars and top and bottom members could be made up separately for fastening together with, maybe, a certain amount of excess length, so that any small variations in height and width required could be made by the builder purchasing these ready-made parts.

The advantage of using steel longitudinals would not be so great, as a stock of these parts would demand a fairly wide variation in length to prevent waste, and each different design of body would entail fresh setting out for drilling. Moreover, a wooden cant rail facilitates the attachment of a wooden roof, a wooden garnish rail the inside finishers, and a wooden bottom side the flooring. Still, if the factory be properly equipped for dealing with metal construction and fitting, these arguments do not apply so forcibly, and if 100 pairs of metal garnish rails can be put in hand at one time, there should' be no special advantage gained by using wood.

Seat Construction.

In America the bus body builder does not have t9 make a garden seat or chair of wood and then reinforce the back and leg on the gangway side with a stiffening iron, and use separate plates for fastening the chair to the floor, lie can buy from a selection of seat irons. These are made in pairs, complete with seat and back support and legs or pedestal foundation. These are ready to fix in the body. The cushion and back are each made up on a board so that they can be directly attached to these irons. The bus builder here also uses steel occasionally for the legs, seat and back supports, making them up himself.

Lightweight Panels.

Although metal has a certain superiority over wood in a large and regular structure such as a bus body, yet when the panels are considered there is the weight factor to take into account, as the superficial area is large even with a small body. A high-class saloon or limousine may have aluminium panels, but for ordinary bus work this wohld be too costly. For this reason plywood is extensively used.

In a medium-sized bus body there would be about BO lb. difference in the weights of steel and plywood panels. This is not of -tremendous-iraportance in itself in a complete vehicle weighing, say, three tons, but weight reduction should always be adopted wherever possible as a matter of principle.

At the last Olympia Show a single-decker was shown built under the Weymann patents. Fabric panelling Would probably save nearly a hundredweight when compared with steel in an average size body. It will be interesting to see how the various licensing authorities view the use of this material for public-service work.

General Appearance.

It is not possible to vary the design of the bus body to any great extent, but the introduction of the chassis witli the low loading-line, by reducing the overall height, has at once improved the general appearance Considerably, because it has done away with much of the top-heavy look, .which is otherwise so difficult to suppress in a vehicle which must have enough headroom for the passenger to stand up in. Of course, the longer the body the less the prominence of this feature. Therefore, in a small body, such as a 14-seater, headroom should be reduced proportionately if licensing regulations allow. Headroom is not so important in a short body, because the passenger is able to gain his seat or reach the door quickly.

• The adoption of seats to face forwards has led to the use of an unbroken surface of panelling from waist to bottom. This looks better than the old recessed rocker panel below the seat line. A nicely balanced curve given to the side and back turnunder and the camber of the roof all help to prevent the vehicle having a mere box-like aspect. Buses designed for private hire and similar work have various features introduced which recall the lines of a limousine or saloon by the inclusion of a domed-top back panel, rounded corners to the windows and the adoption of various interior refinements.

Variation in Design.

There is less monotony in the general appearance of the single-decker than the double-decker owing to the varieties of entrance used. A single-decker used in the Metropolitan Police area has a rear side entrance, whilst those in the provinces may have a similar arrangement or be provided with a front entrance. A bus may be fitted with both front and rear entrances. Variation is again introduced, because there may or may not be a door at the entrance, or the door is dropped on to the bottom step, increasing at the same time the safety factor.

The body which is mounted on the forward-control type of chassis has a different appearance in front from the more conventional pattern. If the driving compartment be carried right across, the bonnet has rather a stumpy look, whilst if the cabin be restricted to the off side only, an unbalanced effect is inevitable ; still, these msthetic considerations must give place to the more practical ones of making the utmost use of the chassis length and wheelbase available.

Seats and Gangways.

The garden seat, with its well-sprung cushion and sloped back-rest, is often very comfortable in itself ; hut, since fares must be low in order to attract a constant steam of passengers, the seats must be placed closely together ; consequently, there is not too much legroom. The feet of the passenger can, however, be placed under the seat in front, the chief source of dis

comfort being the point at which the shins tonch the angle formed by the junction of the bottom of the back and the back edge of the seat. This edge, without much extra trouble, could be rounded over or bevelled off.

Another restriction is the length of the seat designed to carry two passengers. This dimension seldom exceeds 2 ft. 9 ins., and cannot be increased without reducing the gangway below a practical limit, bearing in mind that the overall width•of the body must not be more than 7 ft. 2 ins, in the London area and 7 ft. 13 ins. elsewhere. The smaller dimension also applies to any motorcar weighing under two tons.

Facing Forward Seats and Narrow Gangways.

The riding public has pointed out in the daily Press on various occasions that the new type of London bus, with its crosswise seats, has a less convenient gangway than the old pattern, with its longitudinal seats. These bodies were several inches narrower overall than the pattern now built in spite of their wider central gangway, the advantage being gained entirely by the different seating arrangement. The facing-forward seat is preferred by the public, because the chances of getting a corner seat or solus position are increased, and it is more pleasurable to be seated in this way than sideways. The bus proprietor is also in favour of it, because, above a certain size of body, it is possible to have more seats than with the old arrangement. The longitudinal seat, however, often has to be used as part of the seating arrangement It is the best way of utilizing the space immediately over the wheel arches. The extra width of gangway so provided is of particular value, as it is near the entrance.

Drivers' Cabins.

The design of the driving compartment is perhaps more varied than any other part of the body. The fully enclosed cabin on the off side of the bonnet of a forward-control chassis contrasts strongly with the con

ventional pattern with little or no roof protection, except for a high roof canopy. Adequate ventilation is, necessary for the first kind of cabin ; in fact, some permanent scheme is required such as louvres above the top of the screen and a good air extractor in the roof and provision for releasing the hot air at the-floor level.

The average bus driver is of good physique, so that there should he no cramping of the seating dimensions and a proper relation between seat, pedals and control levers. In theory, some adjustment of the seat should be provided in order to allow for the difference in arm and leg reach of the different men who will drive the same vehicle. All that can he done in this direction is for the shortish man to provide himself with an extra cushion, for his back, whilst a tall man can make the seat higher in a similar manner.

The Small Country Bus.

The small country bus which does not seat more than 14 passengers differs from the town variety not only in size, but, as it replaces the old carrier's van, provision is made for carrying goods and parcels of various descriptions. Country folk, as a matter of tradition, no doubt prefer a rear entrance in the middle of the back of the body, but this is unsuitable for a comparatively fast-moving vehicle which is to be controlled by one man.

The modern country bus can be fitted with a mechanically controlled front door, seats to face forward, and the overall width be reduced to a minimum by having a small gangway with seats each for two on the off side and for one only on the near side, and, of course, an efficient emergency door at the rear.

As a varying quantity of goods has to be carried, a rail is fastened to the roof, and occasionally there is a luggage rack or cratch at the rear. But the most important feature of a country bus is that the seats should be detachable or fold up out of the way, so that any proportion of passengers and goods may be transported.

To facilitate loading, the usual type of emergency door should give place to a pair of double doors such as are fitted to a boxvan.

Longitudinal seats are also quite suitable for the country bus, as there will be no loss of seating capacity, and the increased sociability possible will, in most in stances, be appreciated ; the cost is less and the disposal of the seats made easier. The front entrance can still be used, and the apparent overall height reduced by having a clerestory roof—that is, one having the centre raised, as in a caravan. This style of roof is not suitable for carrying luggage, however.

Double-decker Buses—the Hind Platform.

'As the single-deck body has already been dealt with, It will be unnecessary to discuss the lower saloon of the double deck, comment being confined to the staircase and upper deck.

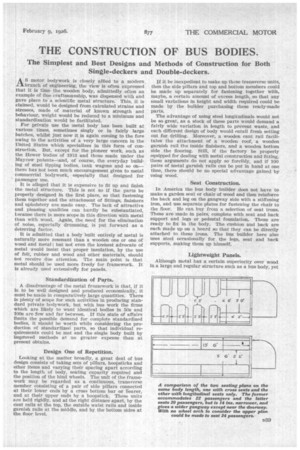

The forward-control chassis has made possible the mounting of a hind platform wide enough so that a separate passage-way is provided for passengers to each deck. The upright landing pole dividing the platform increases its safety, so also does the lower

platform with its single step, or the lowest pattern which does not require any step at all. This variety, however, has been criticised because it is not a convenient pattern for mounting or dismounting while the vehicle is in motion.

Partial Top-deck Protection.

The general design of the double-decker has been well to the fore recently, owing to the fitting of the top deck with a cover, so that it can be used in all weathers with the same amount of comfort as the lower one. The bus proprietor who bas a fleet of vehicles in good running order and operates in a locality where double-saloon buses are allowed to run, may wish to do something towards improving the top-deck protection without incurring the expense of new bodywork.

The front seat on the roof is the best protected, because it is immediately behind the panelled front frame or board of the roof surround. As the bus moves along, the air strikes this front board and is thrown well upward, whereas with a passenger sitting farther back the stream of air has dropped lower. If the height of the front be increased by means of a windscreen, more rows of seats are protected, or if this ,screen is sloped backwards its value is further enhanced. Side protection can also be arranged by the use of just a pair of side wings in front, or extending them as far back as required.

Fitting Tops to Existing Bodies.

Then the full cover to the upper deck can be fitted to an existing body. This solution should have a wide appeal during the transition stage. It will seldom be worth while attempting to stiffen up the side and front frames so that the top has a foundation on the existing top rail.

In any case, it would be advisable to remove the rail and replace it with one of more substance and having a flat top. If this plan were feasible, then the wooden slatted seats could remain also. But the bus proprietor, if he intends spending money in this direction, is well advised to discard 'the whole of the old superstructure, so that the top can be properly put together and cushioned seats adopted.

With an entirely new top, drop windows can be fitted, whereas with a top built up from the waist line only, the windows would have to slide or be made to hinge over horizontally in the centre.

Weight Reduction.

Another point which must not be overlooked is that this alteration of the body would only be suitable for a fairly low chassis. If the chassis be not so suspended, then the matter may be compromised by making the top as light as possible—that is, using roll-up curtains in place of some of the windows. Weight may also be reduced by having a roof of strong waterproof twill instead of wood or of aluminium and wood.

Another suggestion is that the cover should be confined to a portion of the roof only, with a roof extension or canopy at each end. If this were placed " amidships " then the seats would be spaced out so as to provide a row, of open seats in front and one or two seats at the back.