The K.W. Magneto.

Page 19

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

A New Component of American Manufacture. Robust Construction. An Impulse Starter.

We hear, nowadays, very little of the magneto question, which appeared so very likely to become vital a little more than 12 months ago. From personal observation of

all kinds and makes of chassis, it would appear that our British makers are keeping the wheels of industry turning in this respect by utilizing American components. British makers of magnetos are undoubtedly handicapped by Government demands for material more directly deserving the title munitions. This circumstance has been the American maker's chance. and he has, as in other instances, taken goad care to avail himself of it.

Made by a Firm of Repute.

One of the newest components of the kind to reach this country, and having several claims to distinction, is the K.W. It is made by a firm claiming to have had upwards of four years experience in the manufacture of this,class of goods, who, consequently. are able, with some degree of safety, -to 'guarantee its

machines to give good .service. Certainly, if reliability can safely be depended upon to he proportionate to dimensions, the K.W. should easily outlast any other magneto in general use for motor vehicles at the present time. It must be

admitted that the extra amount of material provided allows a bigger factor of safety to be used, provided the quality is the same as that of the stuff put into its smaller brethren. In this respect it is significant that the magnets. which are five in number and to which these remarks apply, are guaranteed to retain their properties for ever.

Windings Do Not Rotate.

A special feature of the design, although not entirely a novel one, is that the windings do not revolve, and they are entirely separate from the armature, -which passes through their centre. As an illustration on page 299 shows, they are placed over the rotor. The latter collects the magnetism from one of the pole-pieces of the magnets, and conducts it through the windings to the other half of the rotor, whence it is transferred

to the other pole-piece. In this manner the electric current is produced in the wiring and transferred by means of the special terminal at, the top of the wiring to the safety spark-gap and to the distributor. It is claimed for this system of wiring that it allows of more thorough insulation, and that it eliminates all stress on the material due to centrifugal force. Further, owing to the circular shape of both primary and secondary windings, it is claimed that a greater number of turns can be obtained with the least possible length of wire. All parts of the magneto are, of course, subjected to very thorough tests, butlit is pointed out that particular attention is devoted to the test of these windings.

P52 Contact Breaker.

The distributor as well as the rotor shafts are carried in ball bearings. The circuit breaker is readily removable, and. comes away eir bloc, and is arranged to provide a range of 30 degrees between the extreme positions of advance and retard_ The platinumtipped contacts are fitted with very substantial amounts of platinum, and the distance between the points is very easily adjusted. The arrangement of the cam is a very simple one. The contact-breaker arm, spring, and make-and-break parts are stationary ; the cam rotates in the centre.

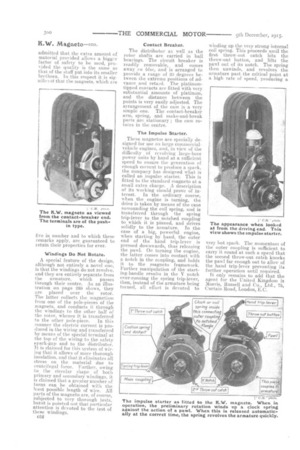

The Impulse Starter.

These magnetos are specially designed for use on large commercialvehicle engines, and, in view of the difficulty of revolving large-bore power units by hand at a sufficient speed to ensure the generation of enough current to produce a spark, the company has designed what is called an impulse starter. This is fitted to the standard magneto at a small extra charge. A description of its working should prove of interest. In the ordinary course, when the engine is turning, the drive is taken by means of the case surrounding the coil spring, and is transferred through the spring trip-lever to the notched coupling to which it is pinned, and drives solidly to the armature. In the case of a big, powerful engine, when starting by hand, the outer end of the hand trip-lever is pressed downwards, thus releasing the pawl. On turning the engine, the latter comes into contact with a notch in the coupling, and bolds it to the magneto framework. Further manipulation of the starting-handle results in the V -notch over-running the spring trip-lever, then, instead of the armature being turned, all effort is devoted to winding up the very strong internal coil spring. This proceeds until the first throw-out catch hits the throw-out button, and lifts the pawl out of its notch. The spring then unwinds, and revolves the armature past the critical point at a high rate of speed, producing a very hot spark. The momentum of the outer coupling is sufficient to carry it round at such a speed that the second throw-out catch knocks the pawl far enough out to allow of the hand trip-lever preventing its further operation until required.

It only remains to add that the agent for the United Kingdom is Morris, Russell and Co., Ltd., 75, Curtain Road, London, E.C.