A cool look at transpor refrigeration systems

Page 42

Page 43

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

by Jerry Rodwell

REFRIGERATED transport has boomed over the past 10 years, and now accounts for a high proportion of the traffic on the road.

And over this period there have been changes in the equipment used — not so much in the type of machinery, but in the sophistication of the plant and of the vehicle bodywork.

There is now more-call for accurate control of load temperature and for powerful equipment able to deal with high outside ambient temperatures. To complement this, body structures have been developed giving very high insulation. .

Bodywork

Two main methods of insulation are used — sprayed polyurethane or polyurethane slab cut and fitted.

There would appear to be a trend towards the use of slab polyurethane, cut and built-in to the panels that form the vehicle walls. Although very high levels of insulation can be achieved in this way, the cost is inevitably high owing to the need to fabricate every little piece of the container walls with insulating material.

So a quicker and simpler solution is to spray the foam directly onto the container walls, either from outside or inside depending on the construction method used. Since it is difficult to get the foam sprayed into every corner, insulation will tend to be slightly inferior to the slab method.

But the bodywork will cost less owing to lower labour content.

Other foam methods include injecting a foaming solution into the void in the bodywork walls and ceilings, where it expands to fill the space with insulant.

Refrigerating equipment

The range of equipment available is little different in type to a decade ago. There are two mechanical systems, onthe-road refrigeration and the hold-over plate system. And in the chemical sector, there is dry ice, liquid CO2 and liquid nitrogen.

Chemical systems depend on a liquid or solid turning to gas and absorbing heat.

Dry ice is still used, often in the simplest manner of throwing a few blocks on lhc top of a ready-cooled load to keep the temperature down over short journeys. This method has become more acceptable — though of course it is completely uncontrollable — with the advent of high-insulation bodywork.

Controllable systems using dry ice include the ICI It oldstreern Gard.. This is intended for local delivery van use, where there may be many drops a day.

It consists of a bunker for up to four

blocks of solid carbon dioxide, over which air is blown by a small fan. The resulting cold air is circulated round the body interior.

Since the fan can be switched on and off by a thermostat, the unit can be used to control temperatures within a range of about 0° C to 10° C .(32°F to 50°F). Maximum cooling capacity with a full charge is 29.6 MJ (28,000 Bt2u).

Since CO2 will not support life — in common with liquid nitrogen — safety switches must be fitted to close down the fan when the body doors are open. And a few seconds wait is essential before entering the body to allow the heavy gas to "fall out."

This type of system is easy to fit, and cheap to buy. But it obviously does not provide enough cooling effect or control for large loads on long hauls.

Liquid carbon dioxide can also be used for refrigeration as in the Distillers Company Ltd DisChil system.

Here, cylinders of liquid CO2 are fitted with a discharge valve so that the gas can be released into the vehicle body. As it expands it cools rapidly and can provide a powerful cooling effect.

Control of the discharge is straightforward, and the liquid becomes half "snow" and half cold CO' vapour. Since the snow is the same substance as dry ice, but covers a much greater surface area, there is a rapid pull-down of tern perature. The snow temperature is the same as that of dry ice — minus 109°F, and it is this that has the main cooling effect, backed up by the cold ge.s. While four cylinders are normally fitted to vehicles, eight can provide the capacity for long-haul work in the largest vehicles at very low temperatures.

Liquid nitrogen

Liquid nitrogen systems, being very simple and fairly cheap to run, have become more popular recently.

British Oxygen markets the Polarstream, using a container similar in principle to a giant vacuum flask to carry the liquid nitrogen. The liquid is discharged via a control valve incorporating a thermostat, and is released into the cargo area. It immediately evaporates and absorbs heat.

Although initial installation costs can be high, owing mainly to the cost of the storage vessel, maintenance is minimal and running costs fairly low.

Giving very rapid pull-down of temperature, the system can be arranged to carry cargo at two or more different temperatures in one vehicle by the use of load dividers. And a vehicle could be used to carry fresh meat one way, and frozen food on the return.

Mechanical systems

The hold-over method utilizes a eutectic solution frozen at the beginning of the trip, and allowed to cool the cargo as it defreezes.

The solution is contained in hollow steel plates, which also have tubing running through them to carry a refrigerant gas — normally Freon 12.

Evaporator plates of this type -sometimes called Dole plates after their inventor — arefitted to the bodywork to provide sufficient surface area to cool the cargo as needed. The are piped up to a refrigerating plant at night when the vehicle is in the depot, and become frozen for use next morning. Sometimes the vehicle is fitted with mobile refrigerating plant for use during the day.

Hold-over plate systems are possibly the cheapest type of refrigerating system of all to run, though these low costs are ususlly based on the use of cheap offpeak electricity to run the refrigerating plant. Any change in off-peak power prices could alter this situation.

Precise control of cargo temperature is difficult to achieve with hold-over plates, and there is a slow pull-down of temperature both initially and after doors have been opened for deliveries. To try to prevent this, double insulating doors are often fitted to vehicles, the inner door being self-closing. This system is normally confined to local-delivery work since the plates are extremely heavy, and the weight penalty would be too great for long-distance high-volume haulage.

On-road refrigeration

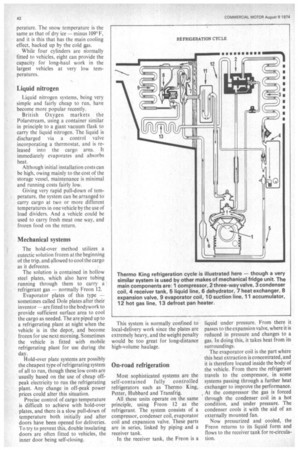

Most sophisticated systems are the self-contained fully controlled refrigerators such as Thermo King, Petter, Hubbard and Transfrig.

All these units operate on the same principle, using Freon 12 as the refrigerant. The system consists of a compressor, condenser coil, evaporator coil and expansion valve. These parts are in series, linked by piping and a receiver tank.

In the receiver tank, the Freon is a liquid under pressure. From there it passes to the expansion valve, where it is reduced in pressure and changes to a gas. In doing this, it takes heat from its surroundings.

The evaporator coil is the part where this heat extraction is concentrated, and it is therefore located inside the body of the vehicle. From there the refrigerant travels to the compressor, in some systems passing through a further heat exchanger to improve the performance. At the compressor the gas is forced through the condenser coil in a hot condition, and under pressure. The condenser cools it with the aid of an externally mounted fan.

Now pressurized and cooled, the Freon returns to its liquid form and flows to the receiver tank for re-circulation. Drive for the compressor and fans is taken from various sourcess; Thermo King uses a direct-coupled diesel engine for the large models, with electric motor back-up for depot work, while Hubbard goes for a diesel-electric generating set, powering the compressor by electricity from the generator which is mounted under the trailer.

Hydraulic drive via pto from the vehicle engine can also be used.

One new refrigeration unit, the Breda Coolstream, contains an air purifier, and a moisture recycling system to control relative humidity. This unit is also claimed to have sufficient capacity\ to cool a load in transit, enabling "field to shop" delivery: Initial cost of this type of machinery is high, but it weighs much less than holdover plates and provides extremely accurate control, as well as being able to heat the load where needed.

Loading up

With so much frozen cargo on the road nowadays, familiarity has bred some contempt for the systems, and operators have come to expect too much from them.

This is most obvious in the cee of frozen meat cargos, where some operators load up fridge vans with warm meat, and then turn the fridge unit hard on to freeze it by delivery time.

But they ignore one thing. The fridge equipment is designed to maintain a low stable temperature, not to freeze the cargo.

So the meat arrives outwardly frozen but warm on the inside — and obviously will deteriorate faster than properly frozen food.

Frozen cargoes must be loaded at the temperature that they should be delivered at, and the fridge equipment must only be expected to maintain that temperature.

It is important also to leave space around the cargo for cold air to circulate, and not to pack parts of the cargo against the van walls, or cold spots might develop.

If refrigerated bodies get damaged on the road, it is essential to get a repair made quickly, or the cargo may be lost. Warm air will get into any body tear very quickly, and the fridge plant just will not be able to cope.

And obviously routine maintenance of the fridge plant must not be ignored. You could end up like one haulier in Cambridgeshire recently , who should have been delivering 10 tons of cooled maggots, but arrived with 10 tons of mixed flies and very lively maggots — and a fridge van wrecked by maggots in the insulation and the fridge unit. The service fitters demanded £30 a day to work on it. Phew!