COMMON MAGNETO TROUBLES AND THEIR CURE.

Page 53

Page 54

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

An Article by an Electrical Expert with Long Experience in Dealing with Magneto Maintenance and the Correcting of Faults.

THE modern magneto is such a reliable piece of apparatus that so long as the engine continues to run satisfactorily it is generally forgotten entirely, and it only needs attention in exceptional cases.

Generally, the exceptional cases re:Solve themselves into a remembrance that the machine requires lubrication for its working parts, and then the interior is swamped with oil until inevitably trouble arises, due to the action of the oil on the insulation which then breaks down.

It May not be out of place, therefore, to remind users that it is

neither ri.ecessary nor desirable to lubricate oftener than about once in every 1,000 miles, and then only very sparingly, 10 drops only being sufficient. The oil should not be engine oil, as, unfortunately, .ta generally used, for some engine oils contain traces of fatly acids which attack the ball races and eventually cause pitting and consequent wear.

The best oil to use is sewing machine oil, which can be purchased at the depots of well-known sewing machine manufacturers. A small. bottle of this will last for years.

,Beyond this matter of lubrication, a magneto requires little attention, other than adjustment of contact-breaker points and an occasional cleaning of the distributor. The latter is rather important. A case is known where the carbon from the wiper brush had completely connected all the segments in the distrihutor. The consequence was that the engine was difficult to start and ,the usual practice of flooding the carburetter was resorted to.

Owing to the current being allowed to go to any or all of the plugs because of the connection of all the segments, •the current took the path of least resistance, this, of course, being to the plug in the cylinder where the inlet valve was open. A. backfire into the carburetter resulted, theY flooded petrol became ignited and the car was set on fire and ultimately destroyed.

This may be, an exceptional case, but it is instanced to show the importance of the simple operation of distributor cleansing. This cannot occur where the distributor is of the jump-spark type—that is to say, where there is no wiper brush, but a revolving arm which passes close to but does not touch the metal segments—nor does this type of distributor require cleaning.

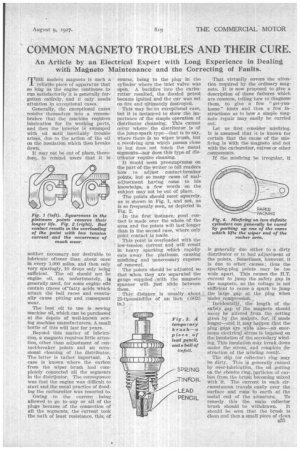

It would seem presumptuous on the part of the writer to tell readers how to adjust contact-breaker points, but So many cases of maladjustment having come to his knowledge, a few words on the subject may not be out of place. The points should meet squarely, as is shown in Fig. I, and not, as is so frequently seen, as depicted in Fig. 2.

In the first instance,good contact is made over the whole Of the area and the points will last longer than in the second case, where only Point contact is made.

This point is overloaded with the 'low-tension current and will result in heavy sparking which rapidly eats away the platinum, causing misfiring and unnecessary expense of renewal.

The points should be adjusted so that when they are separated the gauge supplied with the magneto spanner will just slide between them.

This: distance is usually about 25-tbousandellS of an kith (.0026 That. virtually covers the attention required by the ordinary magneto. It is now proposed to give a description of those failures which are common, telling how to diagnose them, to give a few "get-youhome" hints and then a few instructions as to how a simple magneto repair may easily be carried out.

Let us first consider misfiring. It is assumed that it is known for certain that the cause of the misfiring is with the magneto and not with the carburetter, valves or other components.

If the misfiring be irregular, it is generally due either to a dirty distributor or to bad adjustment of the points. Sometimes, however, it is due to other causes; thus the sparking-plug points may be too • wide apart. This causes the H.T. current to jump the safety gap in the magneto, as the voltage is not sufficient to cause a spark to jump the large :gap at the plug when Under ,compression. • ,

Incidentally " the length of the safetY gap:Of the magneto should /7,?,,e,•ibe altered froin the setting given by tile makers, for, .if . made longer—and it may h,aPpen that the 0:C4-gaps are .wide alse—an. enormous electrical .stress is imposed. on the'lasulation of the secondary winding. This insulation may break, down under the .stress,and complete destruction. of the winding . result. .

The slip. (or collector) ring may he dirty. :This. is ,generallY caused by over-lubrication, the oil getting on the ebonite ring, particles of carbon from. the bruSh becoming mixed with it. The current in such circumstances travels easily over the surface and runs to earth at the metal end of the armature. To remedy this the main collector

brush should be withdrawn. It should he seen that the brush is clean and then a small piece of clean i335 rag wrapped round a pencil should be inserted in the hole from which the brush is drawn, care, however, being taken to retain hold of the end of the rag. Someone should then gently crank the engine, after which the rag should be withdrawn.

The carbon brush must be examined to see that it has not .broken. If so, this may be the cause of the misfiring, as the broken piece will probably make an intermittent path for the H.T. current to earth. Should this be the case, the magneto must be removed and inverted. It will generally be found that the broken piece will then drop out.

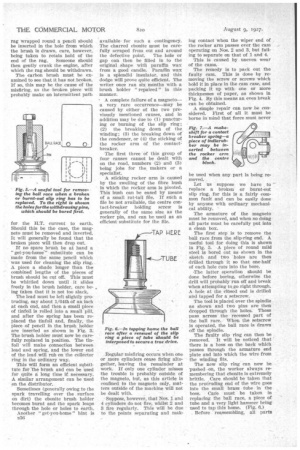

If no spare brush be at hand a "get-you-home" substitute can be made from the same pencil which was used for cleaning the slip ring. A piece a shade longer than the combined lengths of the pieces of brush should be cut off. This must be whittled down until it slides freely in the brush holder, care being taken that it is not too slack.

The lead must be left slightly protruding, say about 1/64th of an inch at each end, and then a small piece of tinfoil is rolled into a small• pill, and after the spring has been replaced the tinfoil and, finally, the piece of pencil in the brush holder are inserted as shown in Fig. 3. The brush holder must now be carefully replaced in position. The tinfoil will make connection between lead and spring, and the lower end of the lead will rub on the collector ring in the ordinary way.

This will form an efficient substitute for the brush and can be used for quite a long time if necessary. A similar arrangement can be used on the distributor.

Sometimes (generally owing to the spark travelling over the surface on dirt) the ebonite brush holder becomes burnt and the spark leaps through the hole or holes to earth.

Another "get-you-home" hint is 1336 availablefor such a contingency. The charred ebonite must be carefully scraped from out and around the defective point. The hole or gap can then be filled in to the original shape with paraffin wax from a good candle. Paraffin wax is a splendid insulator, and this dodge will prove quite efficient. The writer once ran six months with a brush holder " repaired " in this manner.

A complete failure of a magneto--a very rare occurrence—may be caused by either of the two previously mentioned causes, and in addition may be due to (1) puncturing or burning of the slip ring; (2) the breaking down of the winding; (3) the breaking down of the condenser, or (4) the sticking of the rocker arm of the contactbreaker.

The first three of this group of four causes cannot be dealt with on the road, numbers (2) and (3) being jobs for the, makers or a specialist.

A sticking rocker arm is caused by the swelling of the fibre bush in which the rocker arm is pivoted. This bush can be eased by means of a small rat-tail file. If such a file be not available, the centre contact-breaker holding screw is generally of the same size as the rocker pin, and can be used as an efficient substitute for the file.

Regular misfiring occurs when one or more cylinders cease firing altogether, leaving the remainder at work. If only one cylinder misses the trouble is probably outside of the magneto, but, as this article is confined to the magneto only, matters outside of the machine will not be dealt with.

Suppose, however, that Nos. 1 and 4 cylinders do not fire, whilst 2 and 3 fire regularly. This will be due to the points separating and mak

ing contact when the wiper end of the rocker arm passes over the cam operating on Nos. 2 and 3, but failing to separate on that of 1 and 4.

This is caused by uneven wear of the cams.

The remedy is to pack out the faulty cam. This is done by removing the screw or screws which hold it in place in the cam case, and packing it up with one or more thicknesses of paper, as shown in Fig. 4. By this means an even break can be obtained.

A simple repair can now be considered. First of all it must be borne in mind that force must never be used when any part is being removed.

Let us suppose we have to replace a broken or burnt-out slip ring, for this is a fairly common fault and can be easily done by anyone with ordinary mechanical ability. '

The armature of the magneto must be removed, and when so doing all parts must be carefully put into a clean box.

The first step is to remove the ball race from the 811p-ring end. A useful tool for doing this is shown in Fig. 5. A piece of round mild steel is bored out as shown in the sketch and two holes are then drilled through it so that one-half of each hole cuts into the bore.

-The latter operation should be done before boring, otherwise the drill will probably run off and break when attempting to. go right through. A hole at the closed end is drilled and tapped for a setscrew.

The tool is placed over the spindle as shown and two pins are then dropped through the holes. These pass across the recessed part of the ball race. When the setscrew is operated, the ball race is drawn off the spindle.

The faulty slip ring can then be removed. It will be noticed that there is a boss on the back which passes through the armature end plate and into which the wire from the winding fits.

The new slip ring can now be pushed on, the worker always remembering that ebonite is extremely brittle. Care should be taken that the protruding end of the wire goes into the small brass tube in the boss. Care must be taken in replacing the ball race, a piece of tube and a very light hammer being used to tap this home. (Fig. 6-)

Before reassembling, all parts

other than those of ebonite snould he cleaned with petrol.. The ebonite or. other insulators -must be wiped with a slightly oily rag, finishing with a clean soft rag.

Reassembly may now take place. When meshing the driving pinion on armature shaft with distribution wheel, caxeful note•must be taken that the dot on the pinion corresponds with the correct dot on the distributor wheel.

There are always two dotS on this wheel, marked respectively L and R, according to which hand the machine turns when looking at the driving spindle end.

An arrow will be found at this end indicating the direction.

Finally, when assembled the magneto can be .given a coat of dead black paint and fitted to the engine.

A broken contact-breaker spring means a complete stop, and unless a spare be carried or a substitute can be found, it is impossible to proceed. A substitute can, however, be made from brass. . The problem generally is where to find the material! On most vehicles there is somewhere, either on the dashboard or on the body, a'small name-plate or instruction plate. These plates are made of springy brass, and are hard enough to use. The hardness is Warted to them during the process of manufacture.

A strip can be cut from one of these plates similar in dimem, sions to the broken spring. A small hole is drilled in each end and the substitute thus made will work perfectly well and will last a considerable time.

The holes might alternatively be punched through where a drill is not available, but care must be taken not to split the brass.

In the event of the above procedure being impracticable it is possible to get home by cutting a small piece of rubber from a piece of eraser and inserting it between the rocker arm and the centre block as shown in Fig. 7. This will get the vehicle home.