A• Daimler-Benz Road Vehicle Turbine

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

A GAS TURBINE intended for rail A1 vehicles and the heavier types of road vehicle, forms the subject of patent No. 713,346, which comes from Daimler-Benz A.G., Stuttgart-Unterturkheim, Germany. The novel feature is the means uied for obtaining a slowspeed from the output turbine so that it may be directly coupled to the propeller-shaft of a conventional backaxle.

The drawing shows the general layout in which 1 is the output turbine. This is of large diameter so that its high peripheral speed can produce a lower rotational speed. The compressor (2) is driven by a smaller turbine (3) which gives the high speed necessary for an axial-flow compressor. The drive shown at 4 is that to the fuel pump (5) and other accessories.

The unit is expected to run at only 50 per cent, of its full output during normal work, leaving a good reserve for accelerating and hill-climbing. This is not uneconomic because these machines do not become substantially heavier if over-dimensioned.

A HIGH-COMPRESSION COMBUSTION HEAD

A PETROL engine, capable of

employing a compression ratio as high as 15 to 1, is shown in patent No. 713,473, by General Motors Corp., Detroit, Michigan, U.S.A. The novelty resides in the design of the combustion chamber in the cylinder-head; this concentrates the bulk of the compressed charge in a chamber, leaving the minimum possible space directly over the piston.

The drawing shows how the chamber (I) is offset from the 'cylinder. The sparking plug is located in the wall at a point remote from the piston. The piston almost touches the head and the detonation. The patent also states that the compact charge in the chamber burns so quickly that it " anticipates " detonation.

A PRIMING VALVE FOR INJECTION PUMP SYSTEMS

PATENT No. 713,287 (C.A.V. Ltd., Warple Way, London, W.3) deals with a means for ensuring that all air is excluded from an injection system. Normally, before starting, the air has to be expelled by a hand-operated priming pump, but the proposed scheme renders this unnecessary.

In the drawing, 1 is the injection pump and 2 the feed pump which draws fuel from the tank (3). Instead of the feed-pump delivering directly to the injection pump, the fuel must first pass through a special valve (4). The fuel tank is also piped to this, so that when the engine is at rest the injection pump remains full of fuel; this is the position shown in the drawing.

When the engine is started, the feed pump sets up a pressure which lifts the spring-loaded plunger (5) and opens the main fuel path via the filter (6). The plunger also functions as an excesspressure release; if forced high enough it can open a by-pass passage (7).

A TORQUE CONVERTER WITH HIGH-RATIO RANGE

THE normal torque converter has a working range of only about 2 to 1 and has usually to be combined with a mechanical gearbox to obtain a wider range. An improved design, in which this is attained without a serious loss of efficiency, forms the subject of patent No. 713,221, from Ustav pro Vyzkum Motorovych Vozidel, Praha 8, Czechoslovakia..

Referring to the drawing, a stationary casing carries blades (1) and houses the bearings for the input shaft (2) and the output member (3), the latter being driven by a turbine wheel (4). The input shaft drives the impeller (5) and the form of this unit is the chief point of the patent.

It is provided with feathering blades (6) which can be adjusted for angle by a central control-rod (7). The angle can be varied from positive to negative so that a reverse is easily obtainable. The control may be manually per

AN INJECTOR FOR PETROL-AIR SPRAY formed, or some automatic device may be fitted.

The arrangement is said to give a working range up to 6 to 1 reduction.

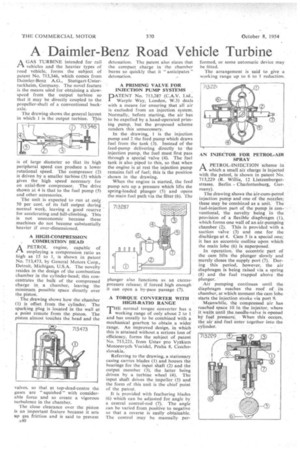

A PETROL-INJECTION scheme in Pi which a small air charge is injected with the petrol, is shown in patent No. 713,229 (R. Willie, 12 Lietzenburgerstrasse, Berlin Charlottenburg, Germany).

The drawing shows the air-cum-petrol injection pump and one of the nozzles; these may be combined as a unit. The fuel-injection part of the pump is conventional, the novelty being in the provision of a flexible diaphragm (1), which forms one wall of an air-pumping chamber (2). This is provided with a suction valve (3) and one for the discharge at 4. Cam 5 is a special one; it has an eccentric outline upon which the main lobe (6) is superposed.

In operation, the eccentric part of the cam lifts the plunger slowly and merely closes the supply port (7). During this period, however, the air diaphragm is being raised via a spring (8) and the fuel trapped above the plunger.

Air pumping continues until the diaphragm reaches the roof of its chamber, at v,ifich moment the cam lobe starts the injection stroke via port 9.

Meanwhile, the compressed air has reached space 10 in the injector, where it waits until the needle-valve is opened bY fuel pressure. When this occurs, the air and fuel enter together into the cylinder.