BACK TO BASICS

Page 54

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

Many winter problems can be avoided by careful basic maintenance, driver training and closer co-operation with fuel suppliers

• In CM this week we describe a selection of products designed to make winter operation easier (page 45). Many claim to provide solutions to the longstanding problem of diesel fuel waxing at low temperature, but there is a growing body of opinion that says the only real solution will come not through any "addons", but by getting "the basics" right.

The basics in this context mean the way in which diesel is stored in bulk, the way it is stored and piped on the vehicle, the vehicle's winter maintenance and, most importantly, the low temperature flow properties of the diesel fuel. It is on this last point that there has been considerable disagreement recently between some operating engineers and their fuel suppliers.

Although most fleet engineers will be reluctant to become deeply involved in the complexities of diesel fuel specifications, several have found that the ability to specify their fuel more precisely can pay dividends, particularly at this time of year.

The Institute of Road Transport Engineers' annual fuel quality survey, to be conducted again this year within the next month, has provided powerful evidence of how much winter grade fuel quality can vary from area to area and from supplier to supplier. It has also highlighted how CFPP (cold filter plugging point), the most commonly quoted diesel fuel property, alone by no means tells the full stoty of a fuel's ability to flow in cold weather.

Cloud point is important too, as is the difference between CITY and cloud point. Without knowing such details of a fuel specification, and indeed what flow improver additives have been mixed at the refinery, an operator could be wasting his time and money on additives to prevent waxing. He will certainly be doing so if he attempts to mix one of them with fuel at a temperature below its cloud point.

The upshot of all this is that one of the most significant steps an operator can take at this time of year to ensure that his vehicles will keep running through the colder weather is to find out more from his fuel supplier about fuel quality.

Oil companies are growing accustomed to a change in attitude among their customers in road haulage. The two most common questions, how much does it cost? and when can you deliver? have been joined by another — what about the quality?

Even when it has been firmly established, however, that the fuel going into the vehicles' tanks is of the required quality, there remains plenty the prudent operator can do to lessen the risk of breakdown during the winter months. Last year Cummins issued a comprehensive service bulletin on the operation of diesel engines in cold climates. Many of the useful tips in it are as valid for any diesel engine as they are for Cummins units.

Cummins says there should be three basic objectives in any programme aimed at preparing a diesel engined vehicle for winter.

(1) reasonable starting characteristics followed by practical and dependable warm-up of engine and equipment.

2 a unit or installation should be as independent as possible from other external influences.

3 modifications which maintain satisfactoty engine operating temperatures with a minimum increase in maintenance of the equipment and accessories.

Under these broad categories come some specific recommendations.

The importance of keeping the electrical system in peak condition during the winter is stressed. Engine manufacturers recommend battery and electrical system capacity to provide adequate cranking down to —18°C (0°F). In colder ambient temperatures, more batteries, or a battery heater may be required.

On starting circuit size and condition, Cummins points out that undersized wire acts as a restriction on electrical power and that loose or corroded wires and connections can consume 50% or more of the available battery power before it gets to the starter.

The correct specification of engine lubrication oil is of particular importance in winter. The pre-winter service should ensure that it is correct.

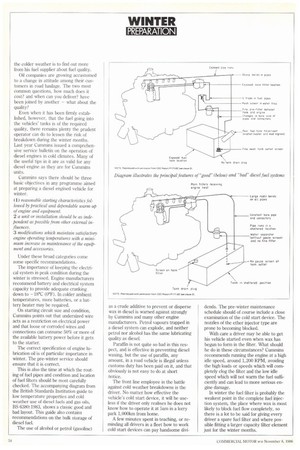

This is also the time at which the routing of fuel pipes and condition and location of fuel filters should be most carefully checked. The accompanying diagram from the British Standards Institution guide to low temperature properties and cold weather use of diesel fuels and gas oils, BS 6380:1983, shows a classic good and bad layout. This guide also contains recommendations on the bulk storage of diesel fuel.

The use of alcohol or petrol (gasoline) as a crude additive to prevent or disperse wax in diesel is warned against strongly by Cummins and many other engine manufacturers. Petrol vapours trapped in a diesel system can explode, and neither petrol nor alcohol has the same lubricating quality as diesel.

Paraffin is not quite so bad in this respect, and is effective in preventing diesel waxing, but the use of paraffin, any amount, in a road vehicle is illegal unless customs duty has been paid on it, and that obviously is not easy to do at short notice.

The front line employee in the battle against cold weather breakdowns is the driver. No matter how effective the vehicle's cold start device, it will be useless if the driver only realises he does not know how to operate it at 5am in a lorry park 1,000km from home.

A few minutes spent in teaching, or reminding all drivers in a fleet how to work cold start devices can pay handsome divi dends. The pre-winter maintenance schedule should of course include a close examination of the cold start device. The nozzles of the ether injector type are prone to becoming blocked.

With care a driver may be able to get his vehicle started even when wax has begun to form in the filter. What should he do in these circumstances? Cummins recommends running the engine at a high idle speed, around 1,200 RPM, avoiding the high loads or speeds which will completely clog the filter and the low idle speed which will not warm the fuel sufficiently and can lead to more serious engine damage.

In winter the fuel filter is probably the weakest point in the complete fuel injection system, the place where wax is most likely to block fuel flow completely, so there is a lot to be said for giving every driver a spare fuel filter and where possible fitting a larger capacity filter element just for the winter months.