The Viking Has Appeal

Page 113

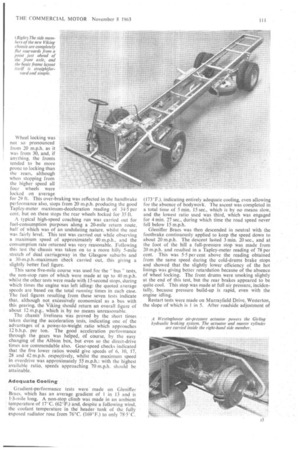

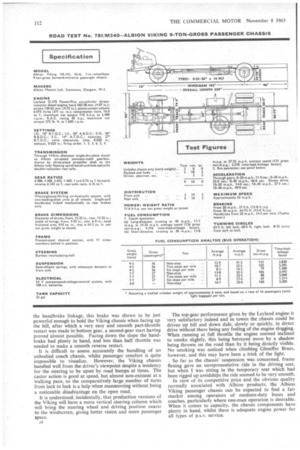

Page 114

Page 115

Page 116

If you've noticed an error in this article please click here to report it so we can fix it.

ROAD TEST: Albion Viking 9-ton-gross pasSenger chassis FOR many years the " Trambus 7 type of passenger vehicle has been popular on the European mainland and in various other overseas territories on the strength of its simple chassis layout and relatively low cost, and whilst chassis of this type have been built in Britain, until recently these have virtually always been produced for export. The advantages of a forward engine location and set-back front axle for front-entrance bodywork are at

last starting to appeal to British users, however, and Albion Motors Ltd. officially enter this field today with their Viking VK.41L chassis, the existence of which has been known to a number of operators for some months now and a passing reference to it was made in our October 4 issue.

The Viking replaces the Victor VT.15A and VT.1713 passenger chassis, both of which had forward-located front axles and as such were unsuitable for front-entrance bodies, but the Victor VT.21L 17-ft. 8-in.-wheelbase forward-axled coach chassis remains in production, as does the VT.19AN pantechnicon chassis. The Viking, which is available in one form only, has a chassis list price of £1,710, and an example can be seen on the Albion stand (No. 114) at the Scottish Motor Show today, this having an Alexander 41-seat, all-metal bus body laid out for one-man operation. With a wheelbase of 16 ft. tin., the Viking is suitable for bodywork with length and width dimensions of 31 ft. 7 in. and 8 ft. 2.5 in respectively, and its designed gross weight rating is 9 tons. Because of its relatively low dry weight of approximately 3 tons 3 cwt., the Viking chassis is suitable for quite heavy bodywork if necessary in standard form, the only proviso being that if the front axle weight exceeds 3 tons 14 cwt. the standard 8.25-20 (14-ply) tyres should be replaced by 9.00-20 (12-ply) equipment at the fronts only.

One of the first Viking chassis was made available to me by Albion Motors for test in Scotland. and the resulting performance figures showed it to be a very satis

factory design, with lively acceleration characteristics, a • fairly low rate of fuel usage, fast hill-climbing ability and ample gradient stop-and-restart performance, and generally good handling. Unfortunately, the braking performance under "crash stop" conditions was not quite up to the standard of the rest of the chassis, being spoilt by excessive wheel locking, but under normal circumstances the brakes behaved satisfactorily, whilst fade resistance was very good indeed.

The Viking has a wheelbase of 16 ft. 1 in., the front-axle centre line being 5 ft. 1.75 in. behind the front of the chassis frame and 5 ft. 10 in. from the front of the towing plate. A Leyland 0.370 6.075-litre six-cylinder diesel is standard, and for most applications this has a net rating of 106 b.h.p. at 2,200 r.p.m., although for coach applications in Britain only a rating of 110 bhp. at 2,400 r.p.m. can be specified. In both cases the maximum torque output is 272 lb. ft. (net) at 1,600 r.p.m.

The engine cooling system is pressurized, and auxiliaries include a 5-5-in, dynamo and a twin-cylinder air-cooled compressor for the braking system. In unit with the engine is the familiar Albion five-speed, constant-mesh gearbox available, as usual, with an overdrive sixth speed. The gear-change lever has a cranked linkage so that it lies slightly to the right of the chassis centreline. The drive is taken from the gearbox through a three-piece propeller shaft with rubber-mounted intermediate bearings, and the standard rear axle is an Albion double-reduction assembly similar to that employed in the Chieftain Super Six goods chassis, this being available with ratios of 5.044, 5.555 or 6-250 to 1.

Alternative to this, however, an Eaton single-speed, spiralbevel axle can be supplied at extra cost, this option being offered because the spiral-bevel axle is quieter in operation than the double-reduction assembly. The Eaton axle is available with ratios of 5-571 or 6-143 to 1.

The front axle is basically a Chieftain Super Six unit also, whilst the braking system has much in common with that goods chassis, consisting of Girling two-leading-shoe units at front and rear with a Westinghouse air-pressure actuator. The brakes on both axles have a diameter of 15-25 in., the front linings being 4-25-in, wide whilst the rears are 6-0-in, wide, giving a total frictional area of 610 sq. in. The single-pull handbrake lever is linked by rods to the rear-axle brakes.

Unusual for a passenger chassis is the absence of rear dampers and, indeed, these are not even available at extra cost. However, as far as can ever be told with a test of an open chassis, the rear suspension, which consists of 60-in. by 3-5-in, semi-elliptic springs, appears to be quite

satisfactory without dampers. At the front, telescopic dampers control 54-in. by 3-in. springs, the dampers being outrigged slightly from the side members and inclined a few degrees from the vertical. As with most current Albion chassis, Burman recirculating-ball steering is employed.

All-bolted chassis

The Viking's chassis frame is an all-bolted assembly, 11 cross-members bracing the 8.5-in. by 2-5-in. by 0-3125-in, pressed side members. The frame assembly incorporates an 8-ft.-wide front member, whilst immediately ahead of each front wheel there is a sturdy cranked outrigger to provide forward body support in the vicinity of the entrance and the driving position.

A 25-gal. fuel tank is standard. The electrical system is 24 V throughout, and equipment supplied with the chassis includes headlamps, side lamps, control box and so forth, non-electrical equipment including—besides instruments— front number plate and driver's tool kit.

Ready for the road, the Viking chassis which I tested weighed 3 tons 8 cwt., and the test load totalled 5 tons 18-5 cwt.: this is equivalent to carrying some 47 passengers and luggage with a body weight of almost 3 tons, which is

.12 all well over the odds. As it was, the rather excessive imposed load meant that the tests were carried out at 10 cwt. above the design maximum, whilst the front-axle load was 4-5 cwt. above the recommended limit for 8.25-20 (14-ply) tyres. The chassis had the lowest available axle ratio6.25-to-l—so was geared as a bus essentially, but the overdrive box was fitted, meaning that the effective top-gear ratio was 4-75 to I. Thus the Viking was tested both as a bus and a coach in order to give a fair indication of its performances under both types of service. As already remarked, the results of the footbrake tests were rather disappointing, mainly because of wheel locking at both front and rear. Mind you, this was not altogether surprising in view of the similarity between the braking systems of the Viking and the Chieftain Super Six and the fact that the latter is designed for a gross weight 2 tons greater than the passenger chassis. A lower hydraulic-line pressure would probably help, since full air pressure (110 p.s.i.) is given for a pedal loading of only 100 lb. Wheel locking was not so pronounced from 20 m.p.h. as it was from 30, and, if anything, the fronts tended to be more prone to locking than the rears, although when stopping from the higher speed all four wheels were locked on average for 29 ft. This over-braking was reflected in the handbrake performance also, stops from 20 m.p.h. producing the good Tapley-meter maximum-deceleration reading of 34-5 per cent, but on these stops the rear wheels locked for 35 ft.

A typical high-speed coaching run was carried out for fuel-consumption purposes along a 20-mile return route, half of which was of an undulating nature, whilst the rest was fairly level. This test was carried out while observing a maximum speed of approximately 40 m.p.h., and the consumption rate returned was very reasonable. Following this test the chassis was taken on to a 'more hilly 5-mile _stretch of dual carriageway in the Glasgow suburbs and a 30-m.p.h.-maximum check carried out, this giving a

slightly better fuel figure. •

This same five-mile course was used for the "bus" tests, the non-stop runs of which were made at up to 40 m.p.h. whilst the other tests were made with 15-second stops, during which times the engine was left idling: the quoted average speeds are based on the total' running times in each case. The fuel figures resulting from these seven tests indicate that, although not excessively economical as a bus with this gearing, the Viking should return an overall figure of about 12 m.p.g., which is by no Means unreasonable.

The chassis' liveliness was proved by the short times taken during the acceleration tests, indicating one of the advantages of a poWer-to-weight ratio which approaches 12 b.h.p. per ton. The good acceleration performance through the gears was helped, of course, by the easy changing of the Albion box, but even so the direct-drive . times are commendable also. Gear-speed checks indicated that the five lower ratios would give speeds of 6, 10, 17, 28 and 42 m.p.h. respectively, whilst the maximum speed in overdrive was approximately 55 m.p.h.: with the highest available ratio, speeds approaching 70 m.p.h. should be attainable.

Adequate Cooling

Gradient-performance tests were made on Gleniffer Braes, which has an average gradient of 1 in 13 and is 1.3-mile long. A non-stop climb was made in an ambient temperature of 17°C. (62'F.) and, despite a following wind, the coolant temperature in the header "tank of the fully exposed radiator rose from 76°C. (169°F.) to only 78-5°C.

(173°F.), indicating entirely adequate cooling, even allowing for the absence of bodywork. The ascent was completed in a total time of 5 min. 15 sec., which is by no means slow, and the lowest ratio used was third, which was engaged for 4 min. 27 sec., during which time the road speed never fell below 15 m.p.h.

Gleniffer Braes was then descended in neutral with the footbrake continuously applied to keep the speed down to about 20 m.p.h. The descent lasted 3 ruin. 20 sec., and at the foot of the hill a full-pressure stop was made from 20 m.p.h. and resulted in a Tapley-meter reading of 78 per cent. This was 5.5 per cent above the reading obtained from the same speed during the cold-drums brake stops and showed that the slightly lower efficiency of the hot linings was giving better retardation because of the absence of wheel locking. The front drums were smoking slightly at the end of this test, but the rear brakes appeared to be quite cool. This stop was made at full air pressure, incidentally, because pressure build-up is rapid, even with the engine idling.

Restart tests were made on Murrayfield Drive, Westerton, the slope of which is 1 in 5. After roadside adjustment of the handbrake linkage, this brake was shown to be just powerful enough to hold the Viking chassis when facing up the hill, after which a very easy and smooth part-throttle restart was made in bottom gear, a second-gear start having proved almost possible. Facing down the slope the handbrake had plenty in hand, and less than half throttle was needed to make a smooth reverse restart.

It is difficult to assess accurately the handling of an unbodied coach chassis, whilst passenger comfort is quite impossible to visualize. However, the Viking chassis handled well from the driver's viewpoint despite a tendency for the steering to be upset by road bumps at times. The castor action is good at speed, but almost non-existent at a walking pace, so the comparatively large number of turns from lock to lock is a help when manceuvring without being a noticeable disadvantage on the open road.

It is understood, incidentally, that production versions of the Viking will have a more vertical steering column which will bring the steering wheel and driving position nearer to the windscreen, giving better vision and more passenger space.

J4 The top-gear performance given by the Leyland engine is very satisfactory indeed and in towns the chassis could be driven up hill and down dale, slowly or quickly, in direct drive without there being any feeling of the engine slogging. When running at full throttle the engine seemed inclined to smoke slightly, this being betrayed more by a shadow being thrown on the road than by it being directly visible. No smoking was noticed when climbing Gleniffer Braes. however, and this may have been a trick of the light.

So far as the chassis' suspension was concerned, frame flexing gave an unrepresentative ride in the driving seat, but when I was sitting in the temporary seat which had been rigged up amidships the ride seemed to be very smooth. In view of its competitive price and the obvious quality normally associated with Albion products, the Albion Viking passenger chassis can be expected to find a fair market among operators of medium-duty buses and coaches, particularly where one-man operation is desirable. When it comes to capacity, the chassis components have plenty in hand, whilst there is adequate engine power for all types of p.s.v. service.