Dodge Produces 24-ton Tractive Unit and 20-ton Six-wheeler

Page 105

Page 106

Page 107

If you've noticed an error in this article please click here to report it so we can fix it.

TODAY Dodge Brothers (Britain) Ltd., enters the maximunv•capacity multiwheeled goods-chassis market with low cost, low weight, six-wheeled rigid and 24-ton tractive-unit models, and in doing so becomes the first British highquantity manufacturer to build vehicles of these types. An example of each of the new designs can be inspected on the Dodge stand at the Scottish Motor Show, which opens today, and it will be seen that both types have much in common with the D.310 15-ton-gross four-wheeler, which was introduced seven months ago and described in our April 5 issue.

The 13.3.10 24-ton tractive unit is available with a choice of two wheelbases, these being 8 ft. 4 in. and 9 ft. 8 in., this latter dimension being the same as for the 15-ton-gross tipper chassis. Apart from its competitive price, this Dodge tractive unit has decided weight-saving advantages, the 9-ft. 8-in.-wheelhase version having a kerb weight, complete with rear wings and a typical fifth-wheel coupling,. of 4 tons 6 cwt., whilst the dry weight is just a few pounds above 4 tons. In each case the shorter-wheelbase version weighs 58 lb. less.

An interesting feature of the longwheelbase models is that the coupling centreline has to be at least 22 in. ahead of the rear-axle centreline, This, of course. goes against current S.TVI.M.T. recommendations, but has the advantage that a better ride can be obtained because or the comparatively long wheelbase and the better weight distribution, whilst there is evidence that the risk of jack-knifing will be reduced also. This 22-in, kingpin position is for the most part only feasible in

fleets where standardization is not critical, hence the 8-ft. 4-in.-wheelbase version (with 10-in, kingpin location), but existing semi-trailers can in some cases be used with the 9-ft. 8-in, model by moving the legs back.

Either tractive unit can be used in conjunction with 27-ft-long semi-trailers, hut even with a 26-ft. semi the kingpin position on the long-wheelbase chassis still has to be 22 in. ahead of the axle centreline. As an indication of weight distribution, figures quoted by Dodge show that the 9-ft. 8-in.-wheelbase tractive unit with 27-ft. semi-trailer and 22-in, kingpin position has a front-axle loading of approximately 3 tons 19 cwt., whilst the drivingaxle loading is approximately 7 tons 7 cwt.. With the same semi-trailer these loadings become 3 tons 6 cwt. and 8 tons respectively in the case of the short-wheelbase tractive unit with 10-in, kingpin location.

The new tractive unit can, in simple term's, be described as being basically the same as the D.310 IS-ton-gross shortwheelbase four-wheeler with certain optional items as standard, including full air braking, Eaton 18802 Mk. 1 two-speed axle with slightly different ratios, and the option of an overdrive sixth speed. Differences include the use of lighter front springs, although the front axle itself is the same; 48-in, rear springs as opposed to 54-in, equipment: and 9.00-20 (12-ply)

tyres on B6.5720 wheels, ai opposed to 10.00-20 (16-ply) tyres on B7.0 wheels.

Apart from its drilling the kingwheelbase tractive unit and the shortwheelbase rigid have the same 10-in. by 3-in. by 0.3125-in, chassis frame. The front springs are 50-in.-long, 3-in.-wide dual-rate assemblies, whilst the single-rate rear springs are 3-5 in. wide. Mules cam and double roller steering is standard, and a I4ydrosteer servo is offered as an option: the longer-wheelbase model has a turning circle of 40 ft. The brakes are Girling cam-type units of 15.5-in. diameter and have Westinghouse air-pressure actuation.

The front brakes have 5-in.-wide linings, whilst the rear linings are 7 in. wide, and the total frictional area is 722 sq. in. The handbrake is a Sackville variable-ratio assembly.

A specially rated version of the A.E.C. AV470 7-685-litre six-cylinder diesel engine is employed in the new tractive unit, this having a net power output of 137 b.h.p. at 2,400 r.p.m, whilst the torque rating is 361 lb. ft. (net) at 1,000 r.p.m. The engine has the Dodge. type of fourpoint mounting, and is in unit with an A.E.C. five speed, constant mesh gearbox with optional overdrive. Only one set of rear-axle ratios are offered-6.5 and 8-87 to I, and the low ratio • gives a theoretical maximum grade ability of 1 in 5.5, whilst maximum speeds in direct and in overdrive are 42 and 56 m.p.h.

On the standard 9.1710-20 tyres, the D.310 tractive unit is most competitively priced at £2,450, this figure including spare wheel and tyre with winch-type carrier, but excluding rear wings and fifth-wheel.

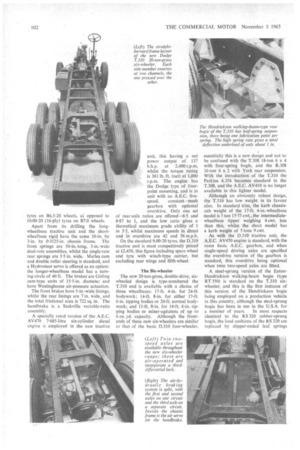

The Six-wheeler The new 20-ton-gross, double-drive, sixwheeled design is type-numbered the T.310 and is available with a choice of three wheelbases: 17-ft. 4-in. for 24-ft. bodywork; 14-ft. 8-in, for either 17-ft. 6-in, tipping bodies or 20-ft. normal bodywork; and 11-ft, 8-in. for 14-ft. 6-in, tipping bodies or mixer-agitators of up to 6 Cu. yd. capacity. Although the frontends of these new six-wheelers are similar to that of the basic D.310 four-wheeler, essentially this is a new design and not to be confused with the T.308 18-ton 6 x 4 with four-spring bogie, and the R.308 16-ton 6 x 2 with York rear suspension. With the introduction of the T.310 the Perkins 6.354 becomes standard in the T.308, and the A.E.C. AV410 is no longer available in this lighter model.

Although an obviously robust design, the T.310 has low weight in its favour also. In standard trim, the kerb chassiscab weight of the 17-ft. 4-in.-wheelbase model is 5 ton 15.75 cwt., the intermediatewheelbase tipper weighing 4 cwt. less than this, whilst the short model has a kerb weight of 5 tons 9 cwt.

As with the D.310 tractive unit, the A.E.C. AV470 engine is standard, with the same basic A.E.C. gearbox, and when single-speed driving axles are specified the overdrive version of the gearbox is standard, this overdrive being optional when twin two-speed axles are fitted.

A steel-sprung version of the EatonHendrickson walking-beam bogie (type RT 350) is standard on the T.310 sixwheeler, and this is the first instance of this version of the Hendrickson bogie being employed on a production vehicle in this country, although the steel-sprung bogie has been in use in the U.S.A. for •

a number of years. In most respects identical to the RS 320 rubber-sprung bogie, the load cushions of the RS 320 are replaced by slipper-ended leaf springs which are .34 in. long and 4 in. wide and which, because of their high rate of 13.900 [bun., have a total deflection of only a bout lin. Lubrication of this bogie suspension is at a minimum, being restricted to one greaser per spring. .

Eaton single-speed axleS are standard except in the case of the short-wheelbase chassis, which has to have the two-speed axles when it is to be used as a tipper. I he only available axle ratio is 7•17 to 1, and this gives a maximum grade ability of 1 in 5.6 and an overdrive-top maximum speed of approximately 51 m.p.h. The two-speed axles used are basically Eaton 6802 assemblies, with linked air-pressure shift mechanisms and lockable thirddifferential. The normal gearing for these axles is 6.14 and 8.54 to I, but where 1-M.-4 gradient ability is required ratios of 7.17 and 9.97 can be supplied. The hither-ratio axles give a low-ratio gradient ability of 1 in 4-6 and an overdrive top speed of 60 m.p.h., this being reduced to 45 in.p.h, in direct drive.

The front axle is the same as that of the 0.310 15-tonner, with a capacity of 5 tons, and the front springs are dual-rate 50-in. by 3-in, assemblies, telescopic dampers being optional. The chassis frame has dual side members, consisting of 10-in. by 3-in. by 0-3125-in main members over which are pr.essed outer channels which extend from the area of the front-spring rear hanger brackets to the extreme end of the frame. These outer channels are standard on all models, and the frames are of all-bolted construction. with nine, seven or six cross-members, according to the wheelbase.

Girling two-leading-shoe .brakes with air-hydraulic actuation are standard, but there is the option of Girling cam brakes with full air-pressure operation. In both cases the brakes are the same size and have a total lining area of 1,024 sq. in-a high figure for a six-wheeler. The front brakes are I5-5-in. by 5-in, assemblies,. whilst the rears are 16-5-in. by 6-in, units. The air-hydraulic system has twin airpressure actuators and master cylinders controlled by a single valve, the first and second axles being on one circuit, whilst the third axle has a separate circuit. The air-pressure system is not split, however. In all cases the single-pull handbrake is air assisted.

Cam Gears high-efficiency steering gear is employed, with a Hydrosteer servo as standard, and the quoted turning circle of the long-wheelbase chassis is 78 ft.. The standard tyres are 10.00-20 (16-ply) at the front and 9.00-20 (14-ply) at the bogie, all being mounted on 10-stud wheels. Radial-construction tyres are optional. A 35-gal. fuel tank is standard, with the option of a 46-gal. tank.

With single-speed axles, the 17-ft. 4-in.wheelbase six-wheeler has a chassis-cab list price of £3,125, thisincluding the sixspeed gearbox. With similar specification, the 14-ft. 8-in.-wheelbase model costs £3,100, whilst the 11-ft. 8-in.-wheelbase chassis with two-speed axles and fivespeed gearbox costs £3,165. The extra cost of the two-speed axles on the two

longer chassis is £75. I.F.M.