Holland Becoming

Page 41

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

an Assembler

By the Technical Editor

ALTHOUGH previously Holland has been considered a market for complete vehicles, the recent show at Amsterdam gave indications that component parts for the assembly of British vehicles in that country will be in increasing demand. It takes time to train engineers in a country which has formerly been mainly agricultural, but such is the trend in Holland. Besides the large proportion

of commercial chassis now being assembled from components produced in Europe and America, two factories ale supplying a steady flow of goods and passenger models for domestic use and a small percentage for export.

Statistics for 1952 show that 5,418 commercial vehicles of all types were imported complete, 2,866 were made or assembled in the country, and 567 were exported. There is a higher import tariff on complete vehicles than on component parts, and further increases may be imposed when the D.A.F. factory at Eindhoven is in full production. At present D.A.F. are building 900 vehicles per year, in addition to supplying all-wheel-drive chassis to N.A.T.O. requirements, and when such contracts have been fulfilled, it is considered likely in Holland that the import tariffs may be raised to protect home production.

Although there are only six eoachbuilding concerns of importance in Holland, the standard of bodywork is exceptionally good. External styling is moderate and the interior finish affords every comfort to the passengers and crew. Dutch construction and use regulations require irt the body two sliding sections in the roof to serve as an emergency exit, and an efficient heater. The conditions governing gangway width and area of door apertures are as rigid as those applicable in Britain, and occasional gangway seats, which are permitted in most European countries, are not allowed in Holland.

Because the country is virtually flat and good highways link the towns and cities, the tendency is to employ relatively small engines in goods and passenger vehicles used 117 domestically and, because of the much lower price of oil • fuel, to install oil engines in chassis of 3 tons or greater capacity. It is estimated that the higher cost of an oil engine in a 3-tanner is recovered in 25,000 miles. Oil fuel is about one-third the price of petrol, but this advantage is offset by a higher annual tax on the compression-ignitioncngined chassis.

As an example of the use of the small engine, Albatros Automobiel of Amsterdam assemble chassis with Albion components, employing the four-cylindered 75 b.h.p. oil engine in conjunction with a five-speed overdrive-top gearbox in a two-axled chassis, which is coupled to a trailer to haul a gross weight of 18 tons. The chassis, a forwardcontrol unit built with a wheelbase of 11 ft. 2 in. or 15 ft. 3 in., is modified to take a cab with an entrance ahead of the axle. In effect, the Albion frame is lengthened at the front overhang by 16 in. and the axle is moved back 12f in. from the normal position.

Steering and other driving controls are changed from the left to the right and brought forward to provide more entrance space ahead of the wheel-arches. The gear-change selector box is attached to the front cross-member, with a link to a small gear lever which projects through the scuttle close to the steering wheel.

Other applications of the small Albion four-cylindered

• unit are found in a left-hand-drive forward-control sixwheeler, rated for a gross weight of over 15 tons, and a Dutch version of the Victor bus chassis of 33 ft. 4 in. length and 18 ft. wheelbase, built for 45 seated passengers, all seats facing forward, front extensions are fitted to the chassis, so that the traditional radiator is screened, because the position of the engine and cooling system is not altered. Albatros Automobiel are, however, proud to display the Albion motif on the front panel.

Although the Albion in this form, and others of similar pattern operating in Holland, have a low power-to-weight ratio when carrying full load, the flat country counterbalances any tendency towards heavy wear of engine or transmission components. Operators told me that it was not unusual for 150,000-250,000 miles to be covered between engine overhauls with the small unit installed.

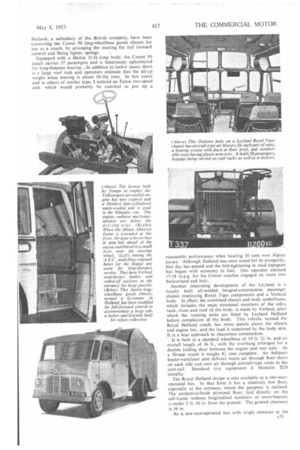

When the Leyland Comet 90 was produced, the announcement of the passenger version was delayed until the Tiger Cub underfloor-engined chassis was fully developed. The Comet passenger chassis with the former 75 b.h.p. oil engine was already popular in Holland, so in the interim, Leyland Holland, a subsidiary of the.British company, have been converting the Comet 90 long-wheelbase goods chassis for use as a coach, by arranging the steering for full forward control and fitting lighter springs.

Equipped with a Hainje 31-ft.-long body, the Comet 90 coach carries 37 passengers and is luxuriously upholstered for long-distance touring. In addition to locker space, there is a large roof rack and operators estimate that the all-up weight when touring is about 10-10i tons. In this coach and in others of similar type, I noticed an Eaton two-speed axle, which would probably be essential to put up a

reasonable performance when hauling 10 tons over Alpine passes. Although Holland was once noted for its prosperity, that day has passed and the belt-tightening in road transport has begun with economy in fuel. One operator claimed 17-18 m.p.g. for his Comet coaches engaged on tours into Switzerland and Italy.

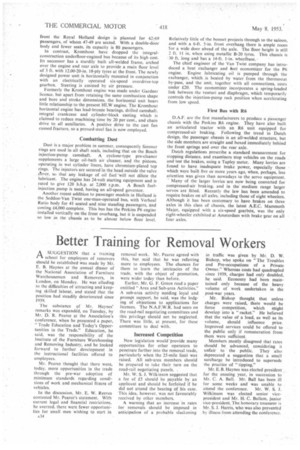

Another interesting development of the Leyland is a locally built all-welded integral-construction passenger chassis employing Royal Tiger components and a Verheul body. In effect, the combined chassis and body undcrframe, which includes the main structural members of the sides, back, front and roof of the body, is made by Verheul, after which the running units are fitted by Leyland Holland before completion of the body. This vehicle, termed the Royal Holland coach, has stress panels above the wheels and engine bay, and the load is supported by the body skin. It is a near approach to chassisless construction.

his built to a standard wheelbase of 19 ft. 21 in. and an overall length of 36 ft., with the overhang arranged for a double folding door between the engine and rear axle. As a 50-seat coach it weighs 8,1 tons complete. An Ashanco heater-ventilator unit delivers warm air through floor -ducts on each side and cool air through aircraft-type vents in the cant-rail. Standard tyre equipment is Michelin b20 metallic.

The Royal Holland design is also available as a one-manoperated bus. In that form it has a relatively low floor, especially at the entrance, where the gangway is inclined. The protective-finish plywood floor, laid directly on the sub-frame without longitudinal members or cross-hearers, is under 2 ft. 10 in. from the ground. The ground clearance is 10 in.

As a one-man-operated bus with single entrance at the

front the Royal Holland design is planned for 62-69 passengers, of whom 47-49 are seated. With a double-door body and fewer seats, its capacity is 80 passengers.

In contrast, Kromhout have dropped the integralconstruction underfloor-engined bus because of its high cost. Its successor has a sturdily built all-welded frame, arched over the engine and rear axle to provide a main floor level of 3 ft. with 12.00-20-in. 18-ply tyres at the front. The newly designed power unit is horizontally mounted in conjunction with an electrically operated six-speed overdrive-top gearbox. Steering is assisted by air pressure.

Formerly the Kromhout engine was made under Gardner licence, but apart from retaining the same combustion shape and bore and stroke dimensions. the horizontal unit bears little relationship to the present HLW engine. The Kromhout horizontal engine has lead-bronze bearings, drilled camshaft, integral crankcase and cylinder-block casting which is claimed to reduce machining time by 20 per cent., and chain drive to all auxiliaries. A positive drive to the cast fan caused fracture. so a pressed-steel fan is now employed.

Combatting Dust

Dust is a major problem in summer. consequently Simmer rings are used in all shaft scats, including that on the Bosch injection-pump camshaft. A cyclone-type pre-cleaner supplements a large oil-bath air cleaner, and the pistons, operating in wet cylinder liners, have chromium-plated top rings. The injectors are secured in the head outside the valve ever, so that any leakage of oil fuel -will not dilute the lubricant. The engine has 24-volt starting equipment and is rated to give 120 b.h.p. at 2,000 r.p.m. A Bosch fuelinjection pump is used, having an all-speed governor.

Another recent addition to passenger models in Holland is the Seddon-Van Twist one-man-operated bus, with Verheul Ratio body for 41 seated and nine standing passengers, and costing £4,000 complete. This bus has the Perkins P6 engine installed vertically on the front overhang, but it is suspended so low in the chassis as to be almost below floor level. Relatively little of the bonnet projects through to the saloon, and with a 6-ft. 5-in, front overhang there is ample room for a wide door ahead of the axle. The floor height is still 2 ft. 11 in. when using metallic B-20 tyres. This chassis is 30 ft. long and has a I4-ft. 1-in. wheelbase.

The chief engineer of the Van Twist company has introduced a heat exchanger and fuel economizer for the P6 engine. Engine lubricating oil is pumped through the exchanger, which is heated by water from the thermostat by-pass, and the unit, together with all connections, costs under £20. The economizer incorporates a spring-loaded link between the venturi and diaphragm, which temporarily controls the injection-pump rack position when accelerating from low speed.

First BUS with R6 D.A.F. are the first manufacturers to produce a passenger chassis with the Perkins 126 engine. They have also built an articulated tractor with an 1(6 unit equipped for compressed-air braking. Following the trend in Dutch design, the passenger chassis is an all-welded structure, but the side members are straight and boxed immediately behind the front springs and over the rear axle.

Dutch regulations prescribe a standard measurement for stopping distance, and examiners stop vehicles on the roads and test the brakes, using a Tapley meter. Many lorries are found to have inadequate brake power, especially those which were built five or more years ago, when, perhaps. less attention was given than nowadays to the servo equipment. Many of the larger lorries are now being converted for compressed-air braking, and in the medium range larger servos are fitted. Recently the law has been amended to require brakes on all axles, including those of eight wheelers. Although it has been customary to have brakes on three axles in this class of chassis, the latest A.E.C. Mammoth Major, equipped with a six-speed gearbox, was the only eight-wheeler exhibited at Amsterdam with brake gear on all four axles.