DRIVING A WEDGE

Page 27

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

INTO VAN DESIGN

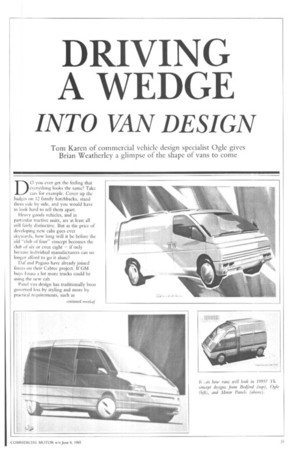

Tom Karen of commercial vehicle design specialist Ogle gives Brian Weatherley a glimpse of the shape of vans to come

D0 you ever get the feeling that everything looks the same? Take cars for example. Cover up the badges on 12 family hatchbacks, stand them side by side, and you would have to look hard to tell them apart.

Heavy goods vehicles, and in particular tractive units, are at least all still fairly distinctive. But as the price of developing new cabs goes ever skywards, how long will it be before the old "club of four" concept becomes the club of six or even eight — if only because individual manufacturers can no longer afford to go it alone?

Dar and Pegaso have already joined forces on their Cabtec project. ft-GM buys Enasa a lot more trucks could be using the new cab.

Panel van design has traditionally been governed less by styling and more by practical requirements, such as maximum payload and cargo space, access and durability. But recently stylists and vehicle designers have begun taking much more interest in the overall shape of the van.

Guessing what the future light van will look like is a precarious business at the best of times so to help me 1 talked to Tom Karen — one of the gurus of vehicle design and managing director of Ogle, the Letchworth based design company.

It is not difficult to find Ogle's influence on commercial vehicles — the evidence can be seen every day on roads throughout Europe. Among the many transport projects Ogle has worked on are Leyland's T45 Roadtrain and C44 Roadrunner cabs, Seddon Atkinson's interior and exterior truck styling and Plaxtons' Panorama II coach body. At the lighter end it also carried out the concept design work on the wide-bodied Sherpa as well as the K2 Sherpa facelift and the design and full-scale modelling for the Austin Maestro van.

In spite of the success of Japanese forward-control vans, most panel vans currently produced in Europe have a conventional or semi-forward control design — witness the Ford Transit, Bedford CF, Freight Rover Sherpa, Iveco Daily, Mercedes-Benz's Bremen range and the SEVEL-built Talbot Express and Fiat Ducat°. Most have retained a stepped front profile with at least some semblance of a bonnet.

But one manufacturer — Renault — took a radical step five years ago when it launched its aerodynamic wedge shaped front-wheel-drive 'End-lc and Master vans. These offered low platform heights and good interior space within a striking body shape.

Many people have suggested that the wedge shape of the Trafic and Master will be the template for future vans. The long awaited Transit van replacement — due to be launched by Ford at the end of the year — is already reported to have a wedge shaped body.

Would all future vans have a wedge design? Torn Karen replied: "There's no escaping the fact that vans will always be a box shape with a front dependent on engine position, and I'm inclined to think that the engine is preferable in the front. Fundamentally, the wedge is a good aerodynamic shape, but that's only half the truth. We do have to do more work on the plan rather than the side elevation, where there could be more benefit.

Although Tom Karen is impressed by Renault's designs he feels that they are rather too angular, particularly around the A-posts and rear body corners which could be "softened" by giving them a greater radius in plan.

Improving the frontal airflow of a van, then, is not simply a matter of increasing the A-post rake. Putting a curve into the rear upright would mean losing some internal space at the rear of the body, but Tom Karen feels these sharp interior corners are often under used when loading anyway.

Car manufacturers are already trying to smooth air flow across the A-post area and Volkswagen has gone as far as enclosing the A-post rain channels on the Golf van to minimise windflow disturbance.

Tom Karen was quick to point out the susceptibility of many of today's high-roof vans to cross winds, particularly when travelling at maximum speeds. To overcome stability problems he reckons that greater radii should also be incorporated in the roof line, lower sills and valances to reduce turbulence or sideways pull.

"Good design" for Tom Karen "brings together genuine practical requirements". The pronounced angles at the front corners of most vans are "just carrying fresh air". Smoothing them out would not only improve the van's wall-to-wall turning circle he maintains, but also reduces the likelihood of knocks and scrapes which these points seem to collect. "Cut the corners away and life is better for manoeuvrability, visibility and aerodynamics".

Two major manufacturers — Ford and General Motors — have already gone along the "smoothing off" road in their wedge shaped Aerostar and Safari vans. It is worth noting, however, that although the Americans are clearly interested in wedge designs they are still building plenty of conventional bonneted vans.

One vehicle that has caught Torn Karen's eye is Ford's Aerovan — designed by Ghia — the manufacturer's in-house design group. Versions of the dual-purpose van and "people mover" have already been seen at European motor shows.

"I've been predicting that kind of vehicle for years — it has amazed the that it hasn't taken off in a bigger way". Manufacturers' recent economic problems could well have delayed its arrival, although Tom Karen feels the Aerovan will prompt greater development of dual-purpose van/passenger models.

Many features from the Aerovan's aerodynamic "one-box" design are already used in the Ford Aerostar van which manages to incorporate a conventional front engine, rear-wheeldrive layout in an attractive body with an impressively low 0,37 cd drag coefficient.

The Aerostar's 905kg (I7.8cwt) maximum payload is comparable with many one-tonne Eurovans. Its 4cum (142cuft) load volume is small by European standards and may indicate the kind of trade-off van operators will have to make for improved aerodynamics.

Some light commercials do not lend themselves to a wedge design, the most obvious being the Luton van. "It is a vehicle too practical to throw away just because of had aerodynamics," says Tom Karen, "although there is room for improvements".

More use of smoother, moulded glass reinforced plastic panels, particularly on the front bulkhead, would be a step in the right direction for him.

One UK bodybuilder — Walkers of Watford — obviously feels the same way. Its award-winning Walker Van body launched at last year's Motor Show proves that Luton vans can be practical and well-styled in spite of difficult design limitations.

'I 'he process of improving aerodynamics, although not infinite, is by no means at an end and Toni Karen expects far more work, particularly on vehicle stability, to be carried out. "Aerodynamics, however, will soon not he the big issue — durability and interior design will," he predicts.

For tractive units containerisation proved an important catalyst, changing designs in the late Sixties.

For Motor Panels, the Coventry-based cab manufacturer, containerisation has been applied further down the weight range. Its concept of vans carrying min containers delivered by larger trucks forms a part of its Cabvan modular light vehicle design project (CM, December 6, 1984).

MP's idea appeals to Torn Karen: "Containerisation makes a lot of sense. It has already shown itself to be cost effective at the heavy end so there must be a niche for it in the van market".

What, then, will these front-wheeldrive, container-carrying, smoothed-out wedge-shaped vans actually be made of? According to Tom Karen pretty much the same thing as today's vans: "Steel is a damn good material and not likely to go out of fashion for sometime". There were, however, "more clever ways in which to use it which can also reduce tooling costs".

While the basic van structure will continue in metal he sees much greater scope for plastics, particularly in sills and valances arid even roof sections. Plastic bumpers are also a logical step, considering the kind of low-speed knocks and bumps vans get. A plastic front end could make stone-chips a thing of the past and also, as he is quick to point out, allow vans to be "facelifted" much more easily by manufacturers.

So much For the outside of the vehicle, but what can a van driver of the future expect the inside to be like? Ten years ago vans were hardly noted for their high levels of comfort. Today, the situation is vastly different, due partly to the advent of more comfortable Japanese and continental vans. Tom Karen believes that van drivers "are entitled to be looked after, just like a car or even a

truck driver — after all they are in them all day".

Keeping a van driver happy is not just a matter of giving him a soft seat and a radio. "The fundamental issues of human factors and ergonomics, whether in cars or vans, haven't been as thoroughly studied as they should be".

'[he rush by many car manufacturers to put microchips in car dashboards is more a case of gimmickry than practicality, Toni Karen suggests. If the new LED displays are to be adopted he feels they must be at least as good as the old fashioned dials. What is more important in Tom's opinion is not so much the way vehicle data is displayed, but how quickly it can be understood by the driver, who on average takes up to two or three seconds to look down at a dashboard, focus, and then refocus on the road.

The potential of vehicle electronics, however, can only be guessed at. Microchip controlled vehicle and engine management systems are already used in a number of expensive saloon cars and it is quite logical to expect more practical versions to be fitted to vans. Tom Karen thinks there is potential for route planning systems using a small on-hoard computer, such as that unveiled recently by Nissan (CM, March 23). "If there is a cost penalty for such electronic devices it could well be paid back in improved productivity, both from the driver and the van" — a factor close to any operator's heart.

Just how long before the new generation of vans will be seen on the roads is difficult to say, although the wedge concept will certainly be strengthened when the new Transit makes it debut. If the new wedge shaped Transit sells as well as the old bonneted one then it could be the beginning of the end for the bonnet.