SPRING-DAMPERS FOR COMMERCIAL VEHICLES.

Page 138

Page 139

If you've noticed an error in this article please click here to report it so we can fix it.

The Reasons for Spring Bouncing and How this Undesirable Disability Can be Overcome. Details of the Commercial Model Houdaille Device.

ONIX a few weeks ago we published several articles dealing with the need for improving the suspension of commercial vehicles, and particularly those used for passenger, services which, naturally, are often run at higher speeds than lorries, and, apart from this, must afford

• passengers the maximum possible degree of comfort.

Many forms of springing were discussed, but it was pointed out that although the laminated form of spring, the origin of which dates back almost to antiquity, has proved most suitable for transport work, as it embodies a certain degree of self-damping which does not exist in any other known form used to any considerable extent, this damping effect depends upon the movements between the leaves when the spring is deflected. Naturally, the more the spring be lubricated the less this friction becomes. Therefore, it would appear better not to lubricate a spring. Froin the point of view of damping-out vibrations, this is fairly satisfactory, but an unlubricated spring loses a great amount of that flexibility which should exist. Conseqilently, to gain one property we are losing another which is also of vital importance.

In the majority of vases. makers 'strongly advise adequate lubrication of the springing, and, in some instances, they make special provision for this, utilizing gaiters and so forth, in which case there still remains the difficulty of lessening the cumulative bouncing effects which are apt to occur, siarticularly where the period of vibration of a spring happens to coincide with, or approximates to. the vibrationary impulses given to a vehicle by road inequalities, which may be fairly evenly spaced, as sometimes occurs where the roads become waved or where pot holes are formed.

Much, of course, depends upon the speed of a vehicle. A bad road can often be taken at a fairly high speed without great discomfort to the passengers, whereas if taken at low speed the bouncing may become most objectionable.

Due of the difficulties confronting designers is that they must often provide springs much stronger than would be justified if flexibility only had to be considered, for the reason that it is when the flexibility is at its best that bouncing is most apt to occur.

Some makers have adopted the expedient of off-setting their axles from the spring centres, and this certainly does something towards obviating cumulative vibrations, as the period of one portion of a spring then becomes different from that of the others, so that the two tend to damp out each other.

A fair amount of success has also been obtained in some cases by utilizing layers of special friction material be tween the laminations of a spring, but the need has shown itself in the majority of instances for some form of external spring-damping device which can easily be fitted to the heavier classes of vehicle.

To the pest of our belief, only one of these designed particularly for such vehicles has been placed on the market," and this only within the past few months. It is the device marketed by the Houdaille hydraulic Suspension Co., Ltd., 41, New Bond Street, London, W.1, which, whilst embodying the same principle as is employed in the model built for light vehicles, has been increased in size and greatly strengthened to make it suitable for commercial vehicles, and particularly heavy passenger-carrying models.

Before describing the new Houdaille we should like to point out that we do not look upon such a device as a shock absorber. It is the springs which take up the shock, whilst the Houdaille acts as a brake upon the recoil, thus preventing or greatly reducing both bowieing and side sway. Incidentally, such a device as this will do much to prevent spring breakage, for it is the cumulative bouncing of a spring which often causes breakage, for the load imposed depeads

upon the weight and the distance through which it acts, and with cumulative bouncing the distance rapidly increases until it is damped out in some manner, so that, where it is permitted, a spring may be called upon to resist shocks two or three times greater than should be necessary. Conversely, where such vibrations are estaped out a spring is not called upon to resist nearly so much loading and may, therefore, be of lighter design and work at its most efficient loading.

Thereis one very important feature in a damping device and that is that it should be capable of regulation. In the Houdaille this is a simple matter, and it is only a question of a minute or less to change the valve-regulating position on a complete set of four dampers. Thus the correct setting for an average load may be found and the dampers adjusted to this, or, when the maximum of comfort is required, they can be altered to suit each particular ioad.

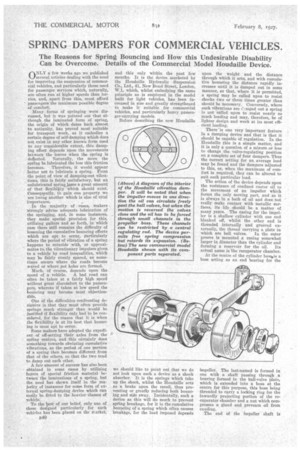

The action of the device depends upon the resistance of confined castor oil to the movement of an impeller which forms the only moving part, and as it is always in a bath of oil and does not really make contact with metallic surfaces, its life should be a matter of many years. The casing for the impeller is a shallow cylinder with one end blanked off, whilst the other end is threaded internally and grooved externally, the thread carrying a plate in which are hail valves. In the outer groove is mounted a casing somewhat larger in diameter than the cylinder and

forming a reservoir for the oil. Its actual name is The recuperator chamber. At the centre of the cylinder basesis a boss acting as an end bearing for the

impeller. The last-named is formed in one with a shaft passing through , a bearing formed in the bell-valve plate, which is extended into a boss at the centre for this purpose, this boss being threaded to carry a locking ring for the inwardly projecting portion of the recuperator chamber and a nut which compresses a gland and prevents oil from exuding.

The end of the impeller shaft is

quared _to carry the lever arm by ifich it is connected to a bracket on. le axle, and threaded for the nut holdig this lever. The whole spindle is so bored out to take the regulating al. If the sketches which we include in ifs article be examined in conjunction ith our description, the action of the )paratus can easily be followed.

When the impeller moves, say, in the irection of the arrows, the ball valves the fixed member lift from their ?as and allow the oil to pass freely om one section of the working chainsr to the other, thus offering no check ) the movement of the blade, and affordig no retarding action. When, however, le impeller reverses its direction of tovement the ball valves close, and the 1 between impeller and plate checks ad controls any further movement, the seing of the oil then depending upon the tting of the regulating rod which perits the oil to flow at a controlled speed

o in the compression chambers to the ee chambers, the oil passing through le regulating apertures in the impeller. Thus, when the body of the instruent is secured to the frame of a vehicle, id the impeller arm is connected to the de in the proper manner, the last named can rise, compressing the spring and without affecting the Houdaille except by lifting the lever, which then acts quite freely. Immediately the spring recoils, however, the damper comes into action and the speed of recoil is retricted to any desired extent, The regulating rod serves merely to open or close the passages in the boas of the impeller, which permit oil to flow between the various chambers.

An oil-filler screw is provided at the uppermost part of the recuperator chamber so that this can be replenished with. oil.

The new Houdaille is designed for, and has been tested out with satisfaction on, vehicles carrying from 30 cwt. to 7 tons. They are marketed in pairs at a cost of £10 10s., special discounts being quoted according to the quantities ordered.

The service depot of the company is 60, Drayton Gardens, South Kensington, London, S.W., where the company will be pleased to see any commercial-vehicle owner who may be interested in the Houdaille, and, at the same time, will arrange to fit a set which can be tried for one month and then bought or returned as desired. It is claimed that the savings effected in connection with reduced tyre usage, less weight due to the obviation of wheel bouncing, the prevention of damage to breakable goods, and the greater custom owing to increased comfort to passengers, will quickly offset the cost of the apparatus, whilst the commercial model can easily be fitted to any make of commercial vehicle.

It must be remembered that the Houdaille device is already most popular on private cars and the lighter types of commercial vehicle—in fact, the sales exceed 225,000 pairs per year.

Up to the present quite a large number of commercial vehicles owned by wellknown users has been equipped with the device, these including 80 lorries for Lambert Bros., who deal in building materials ; 50 lorries for Galeries Lafayette, and 50 for the well-known French grocers, Felix Potin.

One of the important points about the commercial Howlaille is its size, which is so small that a set is almost inconspicuous when fitted. The actual overall length is under 101 ins, and the diameter of the centre chamber di ins., whilst the length of the arm from its fulcrum point is under 7 ins.