THE MAINTENANCE

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

OF OIL

ENGINES

By MAJOR W. H. GODDARD, A.M.I.Mech.E.

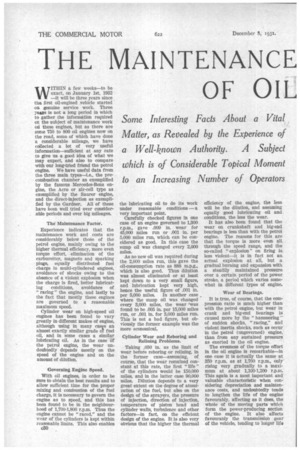

Some Interesting Facts About a Vital Matter, as Revealed by the Experience of a Well-known Authority. A Subject which is of Considerable Topical Moment to an Increasing Number of Operators

WITHIN a few weeks—to be exact, on January 1st, 1932 —it will be three years since the. first oil-engined vehicle started on genuine service work. Three YRILIS is not a long period in which to gather the information required on the subject of maintenance work on these engines, but as there are some 750 to 800 oil engines now on the road, some of which have done a considerable mileage, we have collected a lot of very useful information—sufficient at any rate to give us a good idea of what we may expect, and also to compare with our long-tried friend the petrol engine. We have useful data from the three main types—i.e., the precombustion chamber as exemplified by the famous Mercedes-Benz engine, the Acro or air-cell type as exemplified by the Saurer engine, and the direct-injection as exemplified by the Gardner. All of these have been well tried over considerable periods and over big mileages.

The Maintenance Factor.

Experience indicates that the maintenance work and costs are considerably below those of the petrol engine, mainly owing to the' higher thermal efficiency, more even torque effort, elimination of the carburetter, magneto and sparking plugs, equally distributed fuel charge in multi-cylindered engines, avoidance of shocks owing to the absence of a violent explosion when the charge in fired, better lubricating conditions, avoidance of " racing " the engine, and lastly to the fact that mostly these engines are governed to a reasonable maximum speed.

Cylinder wear on high-speed oil engines has been found to vary greatly in different makes of engine, although using in many cases an almost exactly similar grade of fuel oil, and in some cases a similar lubricating oil. As in the case of the petrol engine, the wear undoubtedly depends mostly on the speed of the engine and on the amount of dilution.

Governing Engine Speed.

With oil engines, in order to be sure to obtain the best results and to allow sufficient time for the proper mixing and combustion of the fuel charge, it is necessary to govern the engine as to speed, and this has been found to be in the neighbourhood of 1,700-1,800 r.p.m. Thus the engine cannot be "raced," and the wear of the cylinders is kept within reasonable limits. This also enables 030 the lubricating oil to do its work under reasonable conditions — a very important point.

Carefully checked figures in one case of an engine governed to 1,300 r.p.m., gave .009 in. wear for 45,000 miles run or .001 in. per 5,000 miles run, which can be considered as good. In this ease the sump oil was changed every 2,000 miles.

As no new oil was required during the 2,000 miles run, this gave the oil-consumption rate as 888 m.p.g., which is also good. Thus dilution was almost eliminated or at least kept down to a very small figure, and lubrication kept very high, hence the useful figure of .001 in. per 5,000 miles. In another case _ where the sump oil was changed every 3,000 miles, the wear was found to be .005 in. per 15,000 miles run, or .001 in. for 3,000 miles run. This is not a bad figure, but obviously the former example was the more economical.

Cylinder Wear and Reboring and Relining Problems.

Taking .030 in. as the limit of wear before reboring or relining, in the former case—assuming, of course, that the wear remained constant at this rate, the first "life" of the cylinders would be 150,000 miles, and in the latter case 90,000 miles. Dilution depends to a very great extent on the degree of atomization of the fuel, but also on the design of the sprayers, the pressure of injection, direction of injection, temperature of piston head and cylinder walls, turbulence and other factors—in fact, on the efficient design of the engine. It is also very obvious that the higher the thermal efficiency of the engine, the less will be the dilution, and assuming equally good lubricating oil and conditions, the less the wear.

It has also been found that the wear on crankshaft and big-end bearings is less than with the petrol engine. The reasons for this are that the torque is more even all through the speed range, and the so-called " explosion " on firing is less violent—it is in fact not an actual explosion at all, but a gradual burning and expansion with a steadily maintained pressure over a certain period of the power stroke, a period which varies somewhat in different types of engine.

Wear of Bearings.

It is true, of course, that the compression ratio is much higher than with the petrol engine, but wear in crank and big-end bearings is caused more by the " hammering " of sudden shocks, "racing," and violent inertia shocks, such as occur in the petrol (ungoverned) engine, than from any sustained pressure as exerted in the oil engine.

The evenness of the torque effort in the oil engine is remarkable—in one case it is actually the same at 350 r.p.m. as at 1,700 r.p.m., only rising very gradually to a maximum at about 1,100-1,200 r.p.m. This again is a most important and valuable characteristic when considering depreciation and maintenance costs, and undoubtedly tends to lengthen the life of the engine favourably, affecting as it does, the whole of the moving parts which form the power-producing section of the engine. It also affects favourably the transmission gear of the vehicle, tending to longer life of the gears and universal joints. Thus we can reasonably say that as regards the second most important item in maintenance of engines, the compression-ignition type can more than hold its own as compared with petrol engines.

• Now we come to the real " heart" of the engine—i.e., the' fuel-injec.-tion pump. Owing to the fact that

• with very few exceptions' the Bosch Pump is almost universally employed, and that very little information is yet available concerning other types of pump, we must base our criticisms on the Bosch pump. This is an extremely simple and foolproofi mechanical; device, consisting of simple plungers working in barrels, cam driven against springs, in which it is difficult for anything to go wrong. The life of the plungers and barrels appears • to be very great judging by the wear after 125,000 miles. It is possibly well over 200,000 miles.

Life of Plungers and Barrels.

Assuming, however, that the plungers and barrels have to he replaced even at 150,000 miles, the cost is very trifling and the work would be not worth taking into consideration. The cams and springs will wear for years. To get at the depreciation allowance for such a pump, we should have to go to a very fine and distant decimal point per mile run. One can only say that the precision work and quality of materials used in these pumps is such that maintenance costs will be extremely small.

There are several types of sprayer, but as in the case of pumps, they are mostly of Bosch make. Some makers, howevet, prefer to use their own. Nozzles should be taken out and cleaned periodically, depending on the mileage run and the work performed. With a spare nozzle carried, a vehicle can be sure Of never being In trouble from this source. A great deal depends on the filtering arrangements provided to ensure

that no foreign matter gets into the system. Pressure of injection also affects the life of sprayers. This varies from 900 lb. per sq. in. to 7,000 lb. Per sq. in.

If the pressure be not over 2,500 lb. per sq. in., one can safely assume the life of a good sprayer to be

200,000 miles. Taking out and cleaning sprayers is easily and quickly carried out. The maintenance work and costs of nozzles is. small, and probably less than the work entailed with sparking plugs in a petrol engine.

Maintenance Costs of Engines with Pre-combustion Chambers.

There are some engines in which the maintenance will not be so favourable. Those oil engines with either pre-combustion chambers, air cells or other designs in which it Is necessary to make use of electric heater plugs to warm up before starting, and in which the compression ratio is of the order of 15 to 1 and up to 164 to 1, which therefore require aCvolt batteries and heavy starter motors, are at somewhat of a disadvantage as regards maintenance costs. This starting gear is bound to be more cestly to maintain.

In the case of engines employing heater plugs, these details must be taken into consideration when calcuhating the cost of efficient mainten

ance. Tho-y should be regularly inspected to see that they are not giving rise to unnecessary work for the battery--in the form of prolonged heavy discharge. for starter operation—by reason of their temporary loW efficiency.

The time that an oil engine will run before decarbonizing is required varies greatly with different types, but in any case is much longer than with petrol engines. Cases have been known where the heads have not been touched for 40,000 miles, but it is goodlpractice to take off the heads once in 15,000 miles or 20,000 miles, clean off the carbon, and lightly grind-in the valves. At the same time the sprayers can be attended to.

Exhaust Temperatures.

Exhaust valves do not (in most types of oil engine) burn out as in petrol engines as the exhaust temperature is only about 450-500 degrees C. as against 1,200 degrees C. in the petrol engine. The valves should last much longer—probably twice as long—than those in a petrol engine. • A greater quantity of the heat from the fuel is turned to useful work, therefore there is less to be dissipated in the cooling water. With tho direct-injection type of engine there is no need for a fan to be used. Fans and their belts are always a cause of expense both in material and labour.

Several of these engines have cylinder liners fitted, but this liner question is still very controversial and applies equally to both the heavy oil and the petrol engine.

Quick Starting a Feature.

An important saving in yearly costs, which applies to all classes of oil •engine, is the quick starting. Taking a large fleet of buses or lorries with petrol engines, the cost both in fuel and time wasted in the winter months is great, because after the engine is running it will not pull its load for some time, and must run at fairly high revs, until the engine is really warm. The ail engine can be started up and will then pull its load at once—a mere efficient state •-of affairs altogether.