Austin Experimenting with Two-strokes'?

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

1:0ATENT No. 722.285 comes from Weaving and The Austin Motor Co.. Ltd., Longbridge Works, Birmingham, and deals with improvements in two-stroke engines. No details are given of the general layout because the patent refers only to the porting arrangements.

The aim is to provide a more complete scavenge than that usually obtained from cylinder-wall ports. In the scheme proposed, the exhaust ports (I), six in number, are set in two opposite quadrants, and the inlet ports (2) are alternated in two groups of four..

The cylinder head is toroidal in outline and the piston crown (3) is generally conical, but is cut away to form what may be called a "boy scout's hat." The result is to direct the incoming charge up the cylinder in two separate streams, which turn over at the top and assist the expulsion of the exhaust gases. If the engine is to be a compression-ignition" unit, it is preferred to make the inlet ports tangential so as to impart a degree of swirl.

A NEW PRINCIPLE IN FILTER CONSTRUCTION DATENT No. 721,592, refers to diffl1 culties arising in the construction of very fine filters: an example which comes to mind is the final-stage filter used in an injection pump. The patentee, R. Stevens, " Dunoon," Coombe Lane, Kingston Hill, Surrey, describes a novel method of producing very fine passages across the surface of a sheet metal plate, several of which can then be assembled to form a pack.

The technique employed is that ..)f the printing industry;' a pattern is first printed on the plate, and then it is immersed in acid to etch away the unprintcd areas, thus forming the required fine grooves.

The depth of the grooves can be very carefully controlled by this method, and an even finer control can be imposed by using electrolytic etching and adjusting the current.

The sheet can be prepared in large sizes and subsequently cut up to the actual sizes required.

Filters of an exceptional degree of fineness, for which the foregoing pro

cesses would be insufficiently delicate can be made by taking a piece of the treated plate and passing it through a rolling process. This would reduce the sheet thickness and with it the groove depth in proportion. By this means, it is claimed, filter passages one micron deep can be made.

VEHICLE WASHING PLANT

PATENT No. 721,450, deals with a rapid washing plant for buses. coaches and the like. The action of the outfit is rapid enough for the vehicle to be driven slowly through it. The patent comes from Dawson Bros., Ltd., Ventnor Works, Gomersal, Leeds.

A steel girder structure supports spray pipes (I and 2) for wetting the vehicle and a pair of cylindrical bristle brushes (3) revolve in contact with the body. Across the lop is a third rotary brush (4) which is pivoted and weighted so as to follow the contour of the roof.

Suggested refinements are a heater in the underground water tank (5) and a waste-preventing light-ray, device which cuts off the water when no part of the vehicle is in the spray region.

AN INJECTION-PUMP GOVERNING SCHEME

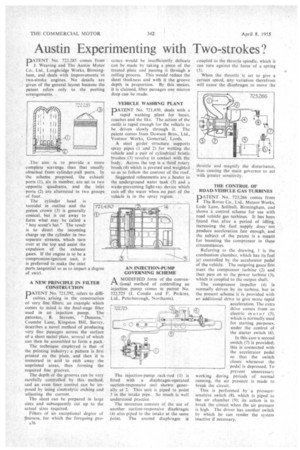

AMODIFIED form of the conventional method of controlling an injection pump comes in patent No. 722,725 (J. Condie and F. Perkins, Ltd., Peterborough, Northants).

The injection-pump rack-rod (i) is fitted with a diaphragm-operated suction-responsive unit shown generally at 2. This unit is piped to point 3 in the intake pipe. So much is well understood practice.

The invention consists of the use of another suction-responsive diaphragm (4) also piped to the intake at the same point. The second diaphragm is coupled to the throttle spindle, which it can turn against the force of a spring (5).

When the throttle is set to give a certain speed, any variation therefrom will cause the diaphragm to move the throttle and magnify the disturbance, bus causing the main governor to act with greater sensitivity.

THE CONTROL OF ROAD-VEHICLE GAS TURBINES

PATENT No. 723.266 comes from The Rover Co., Ltd.. Meteor Works, Lode Lane, Solihull, Birmingham, and shows a control scheme for use with road vehicle gas turbines. It has been found that after a period of idling, increasing the fuel supply does not produce acceleration fast enough, and the subject of the patent is a meant for boosting the compressor in these circumstances.

Referring to the drawing, 1 is the combustion chamber, which has its fuel jet controlled by the accelerator pedal of the vehicle. The outgoing gases first meet the compressor turbine (2) and then pass on to the power turbine (3), which is coupled to the output shaft.

The compressor impeller (4) is normally driven by its turbine, but in the present scheme it is provided with an additional drive to give more rapid acceleration. The extra drive comes from an electric motor (5), which is normally used for starting purposes, under the control of the starter switch (6).

In this case a second switch (7) is provided; this is connected with the accelerator pedal so that the switch closes whenever the pedal is depressed. To unnecessary of normal is made to prevent working during periods running, the air pressure break the circuit.

This is performed by a pressuresensitive switch (8). which is piped to the air chamber (9); its action is to break the circuit when the air pressure is high. The driver has another switch by which he can render the system inactive if necessary.