From the 0

Page 80

Page 81

If you've noticed an error in this article please click here to report it so we can fix it.

rowing BOBIE

by Graham Montgonneri The Engineering Editor examines one of the few assembly-on operations in this country — that of the US-owned Mack in Bolt° Lancs — and assesses its range's chances here.

FEW IMPORTERS assemble in the UK. Since the demise of the Winsford-built Magirus Deutz models, it has been left to the Scottish arm of Volvo to carry on the practice.

It appears, however, that Volvo is not to be alone for long as the American company Mack is soon to build over here. Mack Distributors (UK) Ltd are having a new factory built near Manchester which should be finished in December.

I have been talking to Mack at their present premises in Bol ton about the company's UK performance to date and about some of the more interesting design features of the vehicles.

The model names for Mack trucks refer to the cab rather than the vehicle as there is no such thing as a "standard" Mack. As far as the UK is con cerned, Bolton lays down the spec which is considered ideal for this market. This is then gone over by the Mack engineering division in the States who give final approval. All this means that from the placing of the order to actual delivery takes 150 days, so we are talking about six months from the first enquiry.

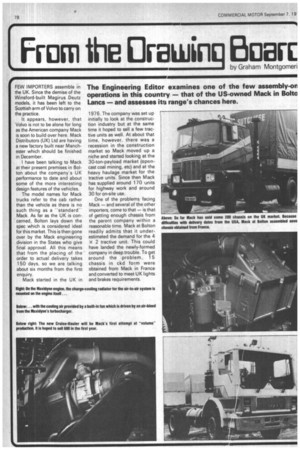

Mack started in the UK in 1976. The company was set up initially to look at the construction industry but at the same time it hoped to sell a few tractive units as well. At about that time, however, there was a recession in the construction market so Mack moved up a niche and started looking at the 30-ton-payload market (opencast coal mining, etc) and at 'the heavy haulage market for the tractive units. Since then Mack has supplied around 170 units for highway work and around 30 for on-site use.

One of the problems facing Mack — and several of the other importers, come to that — is that of getting enough chassis from the parent company within a reasonable time. Mack at Bolton readily admits that it underestimated the demand for the 4 x 2 tractive unit. This could have landed the newly-formed company in deep trouble. To get around the •problem. 15 chassis in ckd form were obtained from Mack in France and converted to meet UK lights and brakes requirements.

-Converted to UK requirenentsis made easier by the act that the Mack Interstater is tot suitable for right-hand-drive :onversion anyway. Until introiuction of the Cruise-Hauler vhich I will come back to shortly no Mack was available in rhd orm.

The assembly of the 'French"' Macks gave the Solon company a chance to look at :kd operation and see what :ould be done. One of the ineresting observations was that here was a surprisingly small ist of shortages with ckd.

The concept of the Mack Aaxidyne engine with its high orque and constant horsepower vas developed about 14 years igo. Mack and Cummins share he same philosophy with enlines in that one basic engine is

manufactured with a wide range of ratings. From the same 11litre (671cuin) turbocharged engine, -Mack can offer outputs from 200 to 300-plus horsepower.

Designed to complement the Maxidyne engine, the Maxitorque gearbox is a triplecountershaft design which has only five speeds, although the basic unit is usually supplemented by an auxiliary box giving an overdrive on fourth and fifth.

Mack claims to have been the first manufacturer to introduce air-to-air charge-cooling for automotive diesel engines. Although many other companies now fit an air-to-air system, they use an auxiliary radiator mounted in front of the conventional coolant radiator. Examples of this include the DKS engine from DAF, the TD7OF in the Volvo F7 and the Perkins T6.354.

The system employed by Mack is slightly different in that the charge-cooling radiator is mounted on the engine and not at the front of the chassis. The necessary cooling airflow is provided by a built-in tip-turbine fan driven by an air-bleed from the turbocharger. This fan draws its own air from a dual-outlet air filter shared with the engine. In the metal, this is a surprisingly compact system and is similar in dimensions to the Cummins and Rolls-Royce air-to-water chargecooling layouts.

This is the type of chargecooling featured on the Interstater and on the new CruiseHauler which was announced at the IRTE conference in May of this year. Available in righthand-drive form, the CruiseHauler is intended to be Mack's -volumemodel in this country. By this Mack means around 600 chassis per year.

A new factory is currently under construction near Oldham to assemble the Cruise-Hauler from ckd kits. Mack is also looking at ways to incorporate some local content in the vehicle but the extent of this is not certain at the moment.

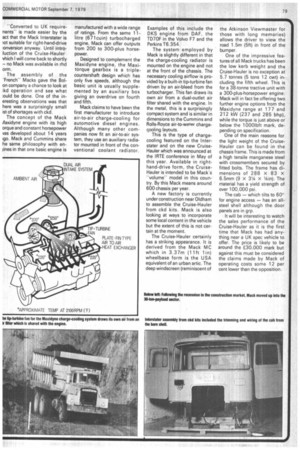

The Cruise-Hauler certainly has a striking appearance. It is derived from the Mack MC which in 3.37m (lift 1in) wheelbase form is the USA equivalent of an urban artic. The deep windscreen (reminiscent of the Atkinson Viewmaster for those with long memories) allows the driver to view the road 1.5m (5ft) in front of the bumper.

One of the impressive features of all Mack trucks has been the low kerb weight and the Cruise-Hauler is no exception at 5.7 tonnes (5 tons 12 cwt) including the fifth wheel. This is for a 38-tonne tractive unit with a 300-plus-horsepower engine. Mack will in fact be offering two further engine options from the Maxidyne range at 177 and 212 kW (237 and 285 bhp), while the torque is just above or below the 1000Ibft mark, depending on specification.

One of the main reasons for the light weight of. the CruiseHauler can be found in the chassis frame. This is made from a high tensile manganese steel with crossmembers secured by fitted bolts. The frame has dimensions of 288 x 83 X 6.5mm (9 X 31/4 x 1/4in). The material has a yield strength of over 100,000 psi.

The cab — which tilts to 60" for engine access — has an allsteel shell although the door panels are in grp.

It will be interesting to watch the sales performance of the Cruise-Hauler as it is the first time that Mack has had anything near a UK spec vehicle to offer. The price is likely to be around the £30,000 mark but against this must be considered the claims made by Mack of operating costs some 12 per cent lower than the opposition.