Forward Control Applied to an 8 h.p. Van Chassis

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

THERE would appear to be ample scope for a forward-control van of the minimum rated capacity, viz., 5-8 cwt. Drapers, milliners, laundrymen and other tradesmen who deal with light but bulky loads would welcome such a vehicle, especially if their operations were of limited scope.

It is, therefore, of interest to note that such a conversion has been effected with success. The chassis is the 8 h.p. Ford and the designer is Mr. Sidney W. Lewis of the Bowes Road Garage and Engineering Co., Ltd., London, N. It is anticipated that the first example of the new model will be exhibited at the forthcoming exhibition of Ford products at the Albert Hall, London.

The nature of the difficulties to be surmounted, and the special features of the design, can best be demonstrated by a brief summary of the alterations.

The bonnet is, of course, removed, and its place is taken by a cowling. The framework supporting the cowl is rigidly but lightly built, so that it adequately supports the radiator casing. The fact that the rearmost portion of the cowl is not vertical, but continues, in a modified degree, the slope of the upper surface, is important, the object being to facilitate the escape of warm air from theengine, directing it downwards and away from the driver's cab, thus at one and the same time cooling both engine and cab. As a further aid to that objective the cowl is lined with asbestos. The starter button and dimmer switch are on the right of this part of the cowl and the choke is on the left.

To carry the steering column and wheel forward presented a difficult problem which, however, has been simply solved. The track rod is moved from behind the axle to the front by the simple expedient of reversing the steering arms. The steering box is sup. ported on a special bracket bolted to the extreme forward end of the main frame. The bracket is bent downwards, thus altering the angle of the column from 26i degrees to 38 degrees. This has the effect of bringing the wheel still farther forward and, in addition, the column itself is shortened by 4 ins.

The pedal assembly is removed from the cross-member on the chassis and is supported by a special bracket neatly designed to fit between the off side of the engine and the frame. Care had to be exercised not to diminish the steering lock, and it was necessary to remould the off-side wing.

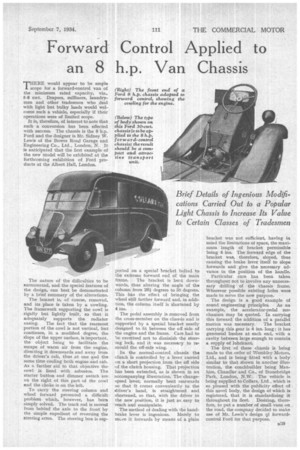

In the normal-control chassis the clutch is controlled by a lever carried on a short projection from the off side of the clutch housing. That projection has been extended, as is shown in an accompanying illustration. The changespeed lever, normally bent rearwards so that it comes conveniently to the driver's hand, is straightened and shortened, so that, with the driver in the new position, it is just as easy to reach and manipulate.

The method of dealing with the hand brake lever is ingenious. Merely to move it forwards by means of a plain bracket was not sufficient, having in mind the limitations of space, the maximum length of bracket permissible being 4 ins. The forward edge of the bracket was, therefore, sloped, thus causing the brake lever itself to slope forwards and give the necessary advance in the position of the handle.

Particular care has been taken throughout not to involve any unnecessary drilling of the chassis frame. Wherever possible existing holes were made to serve the new purpose.

The design is a good example of sound engineering principles. As an example, the accelerator-pedal mechanism may be quoted. In carrying this forward the addition of a parallel motion was necessary. The bracket carrying this gear is 4 ins. long ; it has gunmetal bushes at each end, with a cavity between large enough to contain a supply of lubricant.

The first of these chassis is being made to the order of Wembley Motors, Ltd., and is being fitted with a body similar to that shown in another illustration, the coachbuilder being Manhire, Chandler and Co., of Stonebridge Park, London, N.W. The vehicle is being supplied to Collars, Ltd., which is so pleased with the publicity effect of this novel body, the design of which is registered, that it is standardizing it throughout its fleet. Desiring, therefore, to put a number of small vans on the road, the company decided to make use of Mr. Lewis's design ctt forwardcontrol Ford for that purpose.