Is a Change-speed Gear Necessary ?

Page 2

Page 3

If you've noticed an error in this article please click here to report it so we can fix it.

A Description oi an Internal-combustion Engine in which the Length of the Piston-stroke may be Varied.

The high state of efficiency which has been obtained with modern internal-combustion engines, especially of the type which burn petrol, helix/A, paraffin, or any liquid fuel of a sitnilar nature, has gene far towards placing the motor industry in its present relatively-important position among the engineering industries of the world, but, unfortunately, however efficient such engines may be, or however well designed, they lack, to a great extent, the property of flexibility which is possessed by steam engines. In order to obtain the highest efficiency from a petrol engine, of normal design, the compression pressure, and pistonspeed. must be maintained at uniform values ; all petrol motor vehicles, therefore., are fitted with some form of change-speed gear, by the employment of which a certain amount of variation in ratios between the relative speeds of rotation of the crankshaft and the driving wheels may be made. The steam engine does not suffer from this disadvantage, because the turning effort may be increased or diminished merely by the regulation of the steam pressure on the piston. There have been many attempts, in the past, to produce internal-combustion engines in which the necessary variations in the ratios of leverage, between crankshaft and back axle, might be ohtamed -without the employment of a toothed change-speed gear, but most inventions of this nature have failed, in some way or other, to perform the required functions, and the designs have ultimately been abandoned.

We now have before us a design for, and the records of a series of tests with, a petrol engine in which the length of the piston stroke may be varied, while the volume swept out by

the piston always bears the same ratio to the total working capacity of the cylinders; that is to say, the compression remains practically uniform. The variation in the compression pressure, for any two lengths of stroke, is not mous than five per cent. This engine has been designed by Mr. J. F. Gill, M.Sc., B.Eng., and Mr. T. C. Aveling, A.M.Inst.C.E,, assisted by Mr. A. A. Remington, A.M.I.Mech.E., and its inventors claim that it offers a solution to the direct-drive problem. Whether or no their claims will be

substantiated, by the results obtained in actual tests on the road, with a four-cylinder engine, has yet to be proved, but we are convinced that the design is practicable, and we shall look forward, with interest, to seeing some tests under working conditions.

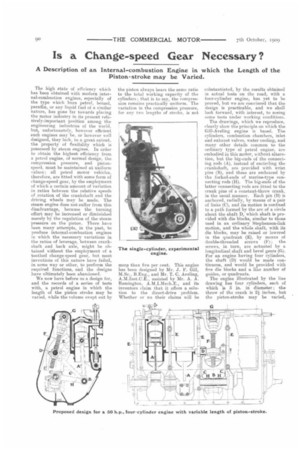

The drawings, which we reproduce, clearly show the principle on which the Gill-Aveling engine is based. The cylinders, combustion chambers, inlet and exhaust valves, water cooling, and many other details common to the ordinary type of petrol engine, are embodied in this motor, without alteration, but the big-ends of the connecting rods (A), instead of encircling the crankshaft, are provided with wrist pins (II), and these are embraced by the forked-ends of marine-type connecting rods (H). The big-ends of the latter connecting rods are fitted to the crank pins of a constant-throw crank, in the usual manner. Each pin (B) is anchored, radially, by means of a pair of links (01, and its motion is confined to a path formed by the arc of a circle about the shaft D, which shaft is provided with die blocks, similar to those used in an ordinary Stephenson-link motion, and the whole shaft, with its die blocks, may be raised or lowered in the quadrant (E), by means of double-threaded screws (F); the screws, in turn, are actuated by a longitudinal shaft and bevel gears (G). For an engine having four cylinders, the shaft (D) would be made continuous, and would be provided with five die blocks and a like number of guides, or quadrants.

The engine illustrated by the line drawing has four cylinders, each of which is 5 in. in diameter ; the throw of the crank is 2 inches, but the piston-stroke may be varied, from a, minimum of 2 in., up to a maximum of 71inches. It is estimated that the engine will develop ;30 h.p. We have prepared three din grams showing the relative positions of the piston rod, connecting rod, and radius rod, for one cylinder of this engine, with a 2 in. stroke, a

41-in_ stroke, and a stroke. In each case the solid lines represent the positions of the rods when the piston is at the top of its stroke, whilst the dotted lines show the relative position of the same parts, at the lower end of the stroke. The three cross-sectioned rectangles show the comparative volumes swept out by the piston for the three lengths of stroke represented by the diagrams. These diagrams also illustrate another point: taking the top of the piston-stroke in the left-hand diagram as the basis of comparison with the others, it may be seen that, as the length of the pistonstroke is increased, the topmost position of the piston is moved further down the cylinder, and this enlargement of the combustion space results in the maintenance of an almost uniform ratio between stroke-vole me, and total volume. At first sight, the construction of this engine appears to be very complicated. and it must be admitted that the cost of production for an engine of a given size will be considerably greater than would that of an engine of normal design, hut, if in actual application to a vehicle on the road the engine fulfils the expectations of the designers, this increased cost, for engine, would be offset by the absence of the need for a change-speed gearbox. Such an engine should he most economical in fuel consumption, and the mechanical efficiency would practivally be constant throughout the whole range of pistonstroke lengths it has generally been admitted that a very large proportion of the work that is lost., in a petrol engine of ordinary design, is that which is absorbed by the friction of the piston against the cylinder walls. An advantage which this engine appears to have over many others is that the angular reaction of pressure on to the walls of the cylinder is reduced to a minimum.

Once an engine of this type is started, and the carburetter adjusted to suit the atmospheric conditions of the day, all further control, over speed or power, may be made by variation in the length of the piston-stroke ; the throttle valve would only be used in cases where the engine, with its minimum piston-stroke, developed more power, or ran at a higher speed, than was needed for the road conditions of the moment. Should this engine come up to its inventors' expectations, the only additional step needed to meet practically all the requirements of the road would be a self-starting device, and a sliding camshaft, by the manipulation of which the engine could be made reversible. With such an ideal power plant, the need for change-speed gearboxes, and reversing gears, would no longer exist.

An experimental engine has already been made on this system, and with it Mr. Gill has conducted a series of interesting tests, at the Birmingham University. The diameter of the cylinder of this model is 3 in., and the piston-stroke may be varied from 1 in. to 3i in. We reproduce a photograph of this engine, and the view shows one end of the crankcase removed, thus exposing, for inspection, the connecting-rod and link motion. The engine was tested for brake-horse-power, at various speeds, and lengths of stroke, and the results of the tests are given in the• accompanying table. Throughout the tests, the compression pressure was about 85 lb. per sq. in. for all lengths of piston-stroke, and, although not recorded in the table, we understand that the highest velocity was obtained with a 11-in. stroke, when the tachometer indicated 2,400 r.p.m. 320 r.p.m. was the slowest speed at which the engine would run with a 3k-in. stroke, but, with a 1 in. stroke, steady running, at 240 r.p.m., could be maintained. Taking the figures from the third and fourth columns of the table, we have plotted a chart, in which piston-speed in feet-per-minute is represented by the ordinates, and brakehorse-power by the abscissas; an examination of this chart reveals the interesting fact that the brake-horsepower bears an almost-direct relation to the piston speed, although, for the lower piston-speeds, there is a considerable drop below the arbitrary line of proportion; the decreased efficiency at slow speeds may be attributed to valve leakage, and other causes that are eliminated when the speed is increased.

In spite of its apparent complica tion, every part of the engine is perfectly accessible when the large cover, which forms one part of the crankcase, is removed.