Contract hire suits Carron

Page 79

Page 80

If you've noticed an error in this article please click here to report it so we can fix it.

By Johnny Johnson

INCOMPATIBILITY of loads is a problem which the general haulier faces constantly. Solving the loadability problem becomes second nature and consolidating cargo with seemingly irreconcilable differences in package shape and size into economic vehicle loads becomes a way of life.

In general, the own-account operator is rarely faced with this situation. Manufacturers of a particular product tend to present their transport manager with goods of a similar nature to distribute and packages tend to be similar in size and shape, too.

When new lines are launched, these are often produced at a different factory so that vehicles suitable for each activity can be based at appropriate points without much difficulty.

The own-account operator encounters loadability problems only when a diversification of products occurs at the same production point. This is more evident, too, when the basic raw material from which products are made lends itself to the manufacture of a variety of goods for widely different applications.

Cannon to cookers

This is what has happened in the case of the Carron Company at Falkirk, iron founders since 1759, which if it has not actually taken to turning swords into ploughshares has certainly diversified from cannon to cookers.

The company is proud of its reputation for fine products. Its cannon were much in demand in the wars of the 18th Century and for its patriotic services at this time King George III incorporated it by Royal Charter which was renewed by the Queen in 1963.

No longer manufacturing the cannonade which revolu tionised naval warfare and the guns which were so effective at Waterloo, Carron now specialises in the manufacture of high-class household kitchen and toilet fittings.

To add to the problems of its transport manager, John Smith, the company has also turned its attention to working in modern materials and produces a range of goods in plastic.

Goods to be transported and distributed to outlets through out the country now includes cast iron drainage pipes; cast iron, steel and plastic sink and washbasin units together with baths in similar materials; central heating radiators; complete shower units; and gas and electric cookers.

Most of the loads emanating from the Falkirk factory are, of necessity, mixed. However, the vulnerability of such products as electric cookers, particularly the enamel, from travelling with iron drainage pipes which are themselves of a brittle nature can be imagined.

Diverse vehicles

Thus, it is not surprising that the vehicle types used to distribute the company's products are diverse.

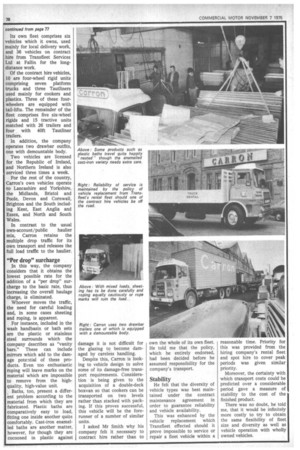

Carron transports 60 per cent of the traffic on its own vehicles and distributes the remaining 40 per cent among a number of public hauliers. Its own fleet comprises six vehicles which it owns, used mainly for local delivery work, and 36 vehicles on contract hire from Transfleet Services Ltd at Fallin for the longdistance work.

Of the contract hire vehicles, 10 are four-wheel rigid units comprising seven platform trucks and three Tautliners used mainly for cookers and plastics. Three of these fourwheelers are equipped with tail-lifts. The remainder of the fleet comprises five six-wheel rigids and 15 tractive units matched with 26 trailers and four with 40ft Tautliner trailers.

In addition, the company operates two drawbar outfits, one with demountable body.

Two vehicles are licensed for the Republic of Ireland, and Northern Ireland is also serviced three times a week.

For the rest of the country, Carron's own vehicles operate to Lancashire and Yorkshire, the Midlands, Bristol and Poole, Devon and Cornwall, Brighton and the South including Kent, East Anglia and Essex, and North and South Wales.

In contrast to the usual own-account/public haulier mix, Carron retains the multiple drop traffic for its own transport and releases the full load traffic to the haulier.

"Per drop" surcharge

In this way, the company considers that it obtains the lowest possible rate for the addition of a "per drop" surcharge to the basic rate, thus increasing the overall haulage charge, is eliminated.

Whoever moves the traffic, the need for careful loading and, in some cases sheeting and roping, is apparent.

For instance, included in the wash handbasin or bath sets are the plastic or stainless steel surrounds which the company describes as "vanity bars." These can include mirrors which add to the damage potential of these products. Even too enthusiastic roping will leave marks on the material which are impossible to remove from the highquality, high-value unit.

Baths, too, present a different problem according to the material from which they are fabricated. Plastic baths are comparatively easy to load, fitting one inside another quite comfortably. Cast-iron enamelled baths are another matter, however, for though they are cocooned in plastic against damage it is not difficult for the glazing to become damaged by careless handling.

Despite this, Carron is looking to vehicle design to solve some of its damage-free transport requirements. Consideration is being given to the acquisition of a double-deck boxvan so that cookers can be transported on two levels rather than stacked with packing. If this proves successful, this vehicle will be the forerunner of a number of similar units.

I asked Mr Smith why his company felt it necessary to contract hire rather than to own the whole of its own fleet. He told me that •the policy, which he entirely endorsed, had been decided before he assumed responsibility for the company's transport.

Stability

He felt that the diversity of vehicle types was best maintained under the contract maintenance agreement in order to guarantee reliability and vehicle availability.

This was enhanced by the vehicle replacement which Transfleet effected should it prove impossible to service or repair a fleet vehicle within a reasonable time. Priority for this was provided from the hiring company's rental fleet and spot hire to cover peak periods was given similar priority.

Moreover, the certainty with which transport costs could be predicted over a considerable period gave a measure of stability to the cost of the finished product.

There was no doubt, he told me, that it would be infinitely more costly to try to obtain the same flexibility of fleet size and diversity as well as vehicle operation with wholly owned vehicles.