New Special Trailers for Oil Exploration

Page 85

If you've noticed an error in this article please click here to report it so we can fix it.

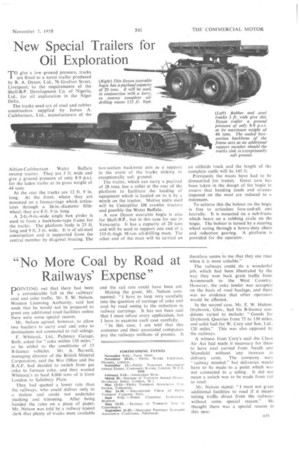

TO give a low ground pressure. tracks are fitted to a novel trailer produced by R. A. Dyson, Ltd, 76 Grafton Street, Liverpool, to the requirements of the Shell-B.P. Development Co. of Nigeria, Ltd., for oil exploration in the Niger Delta. '

The tracks used are of steel and rubber construction supplied by James A. Cuthbertson, Ltd., manufacturers of the Albion-Cuthbertson Water Buffalo swamp tractor. They are 3 ft. wide and give a ground pressure of only 8-9 p.s.i. for the laden trailer at its gross weight of 44 tons.

At the rear the tracks are 12 ft. 9 in. long. At the front, where they are mounted on a forecarriage which articulates through a 36-in.-diameter fifthwheel, they arc 8 ft. 9 in. long.

A 2-ft.-9-in.-wide single box girder is used to form a backbone-type frame for the trailer. The platform body is 25 ft. long and 9 ft. 3 in. wide. It is of all-steel construction and is supported from the central member by diagonal bracing. The box-section backbone acts as a support in the event of the tracks sinking in exceptionally soft ground.

The trailer, which can carry a payload of 28 tons, has a roller at the rear of the platform to facilitate the loading of equipment which is hauled on to it by a winch on the tractor. Motive units used will be Caterpillar D8 crawler tractors and possibly the Water Buffalo.

A new Dyson steerable bogie is also for Shell-B.P., but in this case for use in Venezuela. It has a capacity of 20 tons and will be used to support one end of a 133-ft.-high 38-ton oil-drilling mast. The other end of the mast will be carried on an oilfields truck and the length of the complete outfit will be 145 ft.

Previously the masts have had to be dismantled for transit. Great care has been taken in the design of the bogie to ensure that bending loads and stresses imposed on the mast are reduced to a minimum.

To achieve this the bolster on the bogie is free to articulate fore-and-aft and laterally. It is mounted on a sub-frame which bears on a rubbing circle on the bogie. The bolster is turned by a steering wheel acting through a heavy-duty chain and reduction gearing. A platform is provided for the operator.