kNTROCK BRAKE SYSTEMS: VIRYLL PAY FOR SAFETY?

Page 71

Page 72

If you've noticed an error in this article please click here to report it so we can fix it.

)ULD anti-locking brake systems be le compulsory on commercial vehicles? call for legislation on this, and on the gation to fit anti-jack-knife devices to :s, is repeated from time to time in the Ase of Commons. So far as Anti-locking oncerned, future legislation will probably end on the sums now being done by isticians to show cost-effectiveness in Is of accident prevention, according to type of device and the type of vehicle so ipped.

n the meantime, more and more British :ks are being fitted with brake anti-lock ems intended to make stopping safer and .e controlled, especially on artics. Many hese are in fact engaged on comparative .eises to establish just what extra margin ifety such devices confer.

.ctronic sensing he development of suitable electronic pment over the past few years has )led systems to be evolved that are not eptible to false signals. This is a highly ortant development and some hundreds articulated vehicles equipped with tronic systems are currently operating in UK on normal service or on evaluation cises.

he electronic system has arrived and ems controlling all the wheels of a cle as well as the type applicable to the ing axles of articulated units will oubtedly be used by a fair number of -ators throughout the country in due -se solely because of the merits of the ern. Pending enforcement by regulation, Jai enforcement by a ruling of the ms or the threat of early enforcement 'wing the example of other countries, pment makers in this country are, 'ever, faced with perpetuating projects promise little or no profit. Development s are high and the pay-off on low ntity production will be strictly limited. quantity production of systems for cars Id help to reduce costs but this is at best ng way off.

;evertheless, the electronically-controlled -locking system is here to stay and 30 or .e systems have been evolved in various ntries in recent years. In this country flop was first on the scene some 13 rs ago with the Maxaret which originally a flywheel—overrun type of mechanical or and is now controlled by an tronic unit, systems for air brakes being .ently available off the shelf for fitting to driving axles of artics to prevent :-knifing,

)unlop converted to electronic sensing to iinate response to false signals and to plify the system, and after starting with :hanical sensing, Automotive Products changed to electronic control for the same reasons.

The Mullard company developed an electronic sensor for AP (to an AP specification) and has evolved a complete system in experimental form for applications to the hydraulic brakes of cars which, it is envisaged, will be fitted in high-cost cars in 1974/1975. Announced late last year, a system jointly developed by the Girling and Lucas companies also caters for hydraulic car brakes. Other UK companies are known to be "having a go" with a watchful eye on portents that may indicate what regulations to expect, if any, and extraneous factors that may influence marketing.

When Mr. H. Perring, the chief mechanical engineer of the Department of Environment, attended a demonstration on film of the Eaton Yale and Towne all-wheel electronic system in March, he said that braking was a vast subject covering vast variations of service conditions; anti-locking systems were now applicable commercially and it should be possible to be more precise in the official definition of wheel locking.

The Eaton system will be available in America in January 1972 and will later be produced in this country by Eaton Axles Ltd. A spokesman of the American company mentioned at the function that the system would cost about $100 (£42) an axle which is highly competitive.

As stated by a Dunlop spokesman, UK technicians are masters of innovation. If Dunlop and AP were given the prospect of a big market they could undoubtedly hold their own against intense competition. But in the meantime some commercial vehicle operators are doing cost-effectiveness sums of their own without much thought of accident statistics.

Electrical faults are the most common form of failure, so these operators are apt to view additional electronic equipment as a potential source of extra trouble that is going to increase servicing and down-time charges. In fact, the electronics of the latest systems are reliable and long wearing and give reliable operation so long as suitable wiring, junction boxes and so on are employed.

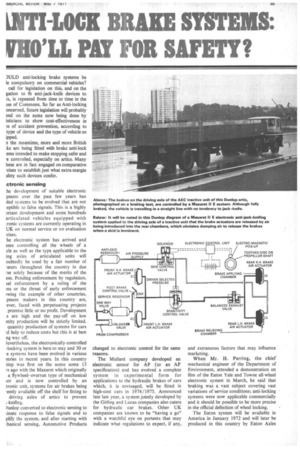

The sensors of the Dunop and AP electronic systems (and of all the known ones) take the form of a toothed ring and an electro-magnetic pick-up which acts as a pulse timer and signals the pulse rate to the electronic control unit.

Dunlop is. concentrating entirely on applications of the Maxaret IIE system to the tractive units of artics as an anti-jack-knifing device and one sensor is used driven by the pinion shaft of the back axle. While AP is also concentrating on tractive-unit applications of the AP Antilok system which will be available to operators for equipping tractive unit drive axles later this year, equipment has been developed for all-wheel applications, a sensor being required for each wheel in the case of nondriven axles.

Dunlop has supplied BRS with 80 systems as part of a Mintec contract for 150 Dunlop units being used, or to be used, for evaluation purposes and AP has supplied 150 sets to BRS on Mintec contract. A total of 300 Maxaret sets has been produced by Dunlop for service applications and some 30 companies are operating vehicles with the system fitted, including most of the major oil companies and many well-known own-account and private haulage companies. It is anticipated that around 500/800 sets will be sold this year.

Service evaluation Antilok has been fitted to the tractive units of a number of large private operators for evaluation in a variety of servi conditions. For test purposes, Antilok been fitted to all the axles of a Ford D8 three-axle semi-trailer and to the seem& brake system, incorporating spring brak of a two-axle rigid to provide all-wh control. It has also been appli experimentally to cars.

In the opinion of Dunlop technicians I need to prevent jack-knifing of artics is such importance that it should be I foremost objective in applications anti-locking systems. The cost of equipmi for fitting to an existing vehicle is relativl high at about £240 partly because it necessary to modify the air actuators.

Release of the brakes (on the threshold skidding) is provided by admitting air to 1 rear of the actuator chamber which considered preferable to dumping air obtain release—when a standard type actuator is used—on the score of prec control and low air consumption.

The system gives rapid release of air the critical wheel deceleration speed wk reapplication is relatively slow, and it ci out at a speed of 4 mph. If jack-knifing prevented, the lesser evil of trailer swing still a potential hazard and it is notable th according to Dunlop, the compan semi-trailer anti-roll air suspension grea reduces trailer-swing tendencies.

Special features of the AP system jock a pressure-modulator valve which lim release of the brakes to the minimum tral required, eliminates oscillation of the axle a makes control by the electronic unit It critical. Future developments will probat include extending the area of electronic cc trol. A tractive-unit drive-axle system v cost about 150. In the AP view, an k wheel system can give optimum utilizati of all the brakes on the vehicle with a variation of axle loading and centre gravity, whereas the use of load sensi valves may result in under-utilization of t brakes of one or more axles. An AP tec nician who attended the Eaton, Yale a Towne demonstration noted the claim ti• an anti-locking system could be used prevent wheel spin when applied to a drivi axle. And he confirms that this could be doi