The Prevention of Side-slip.

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

A Description of Newcomb's Latest Device to Overcome this Evil.

The attachment which we illustrate at the foot of this page is an extremely interesting mechanism devised be Mr. S. W. Newcomb, of the Newcomb Non-Skid Syndicate, Limited, Broad Street House, E.C., for checking, in its early stages, the side-slip of motorbuses, lorries, or other self-propelled vehicles. In its earlier form, Mr. Newcomb's device consisted of two inclined wheels, which were suspended from the rear axle, and these wheels were shod with rubber tires. The idea was that, when the vehicle evinced a tendency to slip sideways, either of these two wheels would resist the tendency and, in this attempt, they would act like wedges, and effectively stop the sideways progress of the vehicle. The device, as then made, however, failed in its object, chiefly because the wheels were shod with rubber tires. Another reason for this disappointing result was, in some cases, the fact that the inclination of the anti-sideslip wheels varied according to the condition of the drivingwheels' tires. When these were badly worn, the angle of the small wheels was very much greater than that for which they were originally designed.

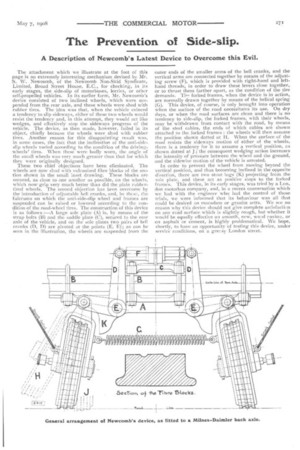

These two chief objections have been eliminated. The wheels are now shod with vulcanised fibre blocks of the section shown in the small inset drawing. These blocks are secured, as close to one another as possible, on the wheels, which now grip very much better than did the plain rubbertired wheels. The second objection has been overcome by the introduction of adjustable hell cranks, and, by these, the fulcrums on which the anti-side-slip wheel and frames are suspended can be raised or lowered according to the condition of the road-wheel tires. The construction of this device is as follows :—A large sole plate (A) is, by means of the strap bolts (B) and the saddle plate (C), secured to the rear axle of the vehicle, and on the sole plates two pairs of bell cranks (I), I)) are pivoted at the points (E, E); as can be seen in the illustration, the wheels are suspended from the outer ends of the smaller arms of the bell cranks, and the vertical arms are connected together by means of the adjusting screw (F), which is provided with right-hand and lef thand threads, in order to draw these levers close together, or to thrust them farther apart, as the condition of the tire demands. The forked frames, when the device is in action, are normally drawn together by means of the helical spring (G). This device, of course, is only brought into operation when the surface of the road necessitates its use. On dry days, or when the road surfaces are clean and there is no tendency to side-slip, the forked frames, with their wheels, may be withdrawn from contact with the road, by means of the steel cables, the ends of which cables are shown attached to the forked frames : the wheels will then assume the position shown dotted at H. When the surface of the road resists the sideways motion of either of the wheels, there is a tendency for it to assume a vertical position, as shown dotted at J; the consequent wedging action increases the intensity of pressure between the wheel and the ground, and the sidewise motion of the vehicle is arrested.

In order to prevent the wheel from moving beyond the vertical position, and thus becoming inclined in the opposite direction, there are two stout lugs (K) projecting from the sole plate, and these act as positive stops to the forked frames. This device, in its ,early stages, was tried by a Lon_ don motorbus company, and, in a recent conversation which we had with the engineer who had the control of those trials, we were informed that its behaviour was all that could be desired on macadam or granite setts. We see no reason why this device should not give complete satisfaction on any road surface which is slightly rough, but whether it would be equally effective on smooth, new, woed raving, or on asphalt or cement, is highly problematical. We hope, shortly, to have an opportunity of testing this device, under service conditions, on a greasy London street,