A PRIZE OF TEN SHILLINGS is awarded each week to

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

the sender of the best letter which we publish en this page; all others paid for at the rate ora penny a line, with. an allowance for photographs. All notes are edited before being . publi,shed. Mention your employer's name, in confidence, as eridenee of good faith. Address _D., 211, and F. " The C11711777erCial Motor," 7-15, Rosebery Avenue, London, EX'.

Lamps Alight.

Light your -lamps at 9.44 in London, 10.55 in Edinburgh, 10.12 in Newcastle, 10.7 in Liverpool, 9.57 in Birmingham, 9.54 in Bristol, and 10.49 in Dublin.

Reboring a Four-cylinder en bloc Casting.

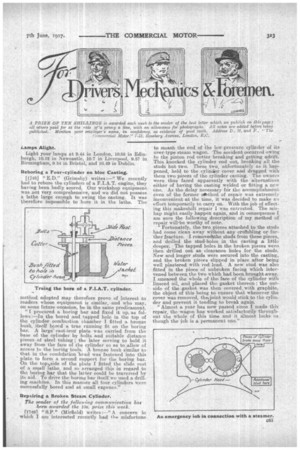

[1.748j " ED." (Grimsby) writes:—" We recently had to rebore the cylinders of a F.I.A.T. engine, they having been badly scored. Our workshop equipment was not very comprehensive, and we did not possess a lathe large enough to swing the casting. It was therefore impossible to bore it in the lathe. The

method adopted may therefore prove of interest to readers whose equipment is similar, and who may, on some future occasion, be in the same predicament. "I procured a. boring bar and fixed it up, as follows :—In the bored and tapped hole in the top of the cylinder combustion chamber I fitted a bronze bush, itself bored is true running fit on the boring bar. A large castdron: plate was carried from_ the base of the cylinder by bolts and suitable distance pieces of steel tubing ; the later serving to hold it away from the face of the cylinder so as to allow of access to the boring tools. A bronze bush similar to • that in the combdstion bead was fastened into this plate to form a second support for the boring bar. On the topside of the plate I fitted the slide rest of a small lathe, and so arranged this in regard to the boring bar that the latter could be traversed by its aid. To drive the boring bar itself we used a drilling machine. In this manner all four cylinders 'were successfully bored and at small expense."

Repairing a Broken Steam Cylinder.

The sender of the following communication has been awarded the 10s. prize this week.

[1749] " S.P." (Mirfield) writes :—" A concern in which I am interested recently had the misfortune

to smash the end of the low-,pressure cylinder of its over-type steam wagon. The accident occurred owing to the piston rod cotter breaking and getting adrift. This knocked the cylinder end out, breaking all the studs but two. These two, unfortunately as it happened, held to the cylinder cover and dragged with them two •pieces of the cylinder casting. The ownefs were thus faced apparently with the alternatives either of having the. casting welded or fitting a new one. As the delay necessary for the accomPlisluneut even of the former niftthod of repair was extremely . inconvenient at the time, it was decided to make al effort temporarily to carry on. With the job of effecting this makeshift repair I was entrusted. The mishap might. easily happen again, and in consequence I. am sure the following description of my method of repair will.he worthy of note. 'Fortunately, the two pieces attached to the studs had come -clean away without any cruinloling or further fracture. I removedithe studs from these pieces, and drilled the stud-holes in the casting a little deeper. The tapped holes in the broken pieces were then drilled out as clearance holes for the studs. New and longer studs were secured into the casting, and the broken pieces slipped in place after being well plastered with red lead. A new stud was also fitted in the piece of unbroken facing which intervened between the two which had been brought away. I smeared the whole of the face of the cylinder with linseed oil, and placed the gasket thereon ; the outside of the ,gasket was then covered_ with graphite, the object of this being to ensure that whenever the cover was removed, thevjoint would stick to the cylinder and prevent it tending to break again. "Almost a year has now passed since I made this repair, the wagon has worked satisfactorily throughout the whole of this time and it almost looks though the job is a permanent one."