Progress, DAF style

Page 25

Page 26

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

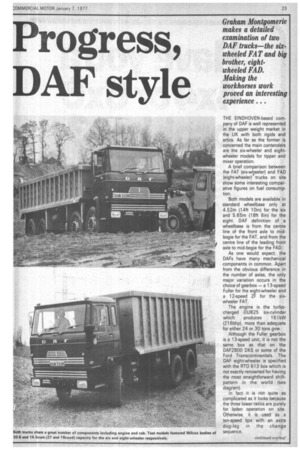

THE EINDHOVEN-based company of DAF is well represented in the upper weight market in the UK with both rigicis and artics. As far as the former is concerned the main contenders are the six-wheeler and eightwheeler models for tipper and mixer operation.

A brief comparison between the FAT (six-wIreler) and FAD (eight-wheeler) trucks on site show some interesting comparative figures on fuel consumption.

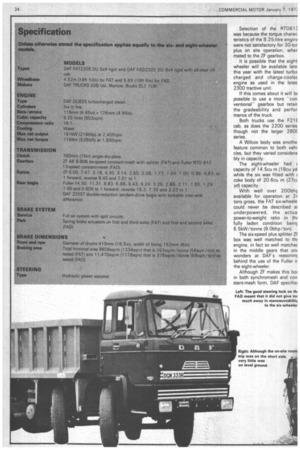

Both models are available in standard wheelbase only at 4.52m (14ft 10in) for the six and 5.65m (18ft 6in) for the eight. DAF definition of a wheelbase is from the centre line of the front axle to midbogie for the FAT, and from the centre line of the leading front axle to mid-bogie for the FAD.

As one would expect, the DAFs have many mechanical .components in common. Apart from the obvious difference in the number of axles, the only major variation occurs in the choice of gearbox — a 13-speed Fuller for the eight-wheeler and a 12-speed ZF for the sixwheeler FAT.

The engine is the turbocharged DU825 six-cylinder which produces 161 kW (216bhp), more than adequate for either 24 or 30 tons gvw.

Although the Fuller gearbox is a 13-speed unit, it is not the same box as that on the DAF2800 DKS or some of the Ford Transcontinentals. The DAF eight-wheeler is specified with the RTCI 613 box which is not exactly renowned for having the most straightforward shiftpattern in the world (see diagram).

In fact it is not quite as complicated as it looks because . the three lower ratios are purely for laden operation on site. Otherwise, it is used as a ten-speed box with an extra dog-leg in the change sequence. Selection of the RT061:: was because the torque,charac teristics of the 8.25-litre engin( were not satisfactory for 30-tor plus on site operation, wher mated to the ZF gearbox.

It is possible that the eight wheeler will be available late this year with the latest turbo charged and charge-coole( engine as used in the fates 2300 tractive unit.

If this comes about it will b( possible to use a more "con ventional" gearbox but retair the gradeability and perfor mance of the truck.

Both trucks use the F21E cab, as does the 2200 series though not the larger 280( series.

A Wilcox body was anothe feature common to both vehi cles, but they varied considera bly in capacity.

The eight-wheeler had capacity of 14.5cu m (18cu yd while the six was fitted with ( coke body of 20.6cu m (27c( yd) capacity.

With well over 200bhr available for operation at 2z tons gross, the FAT six-wheele could never be described a! underpowered, the actua power-to-weight ratio in th( fully laden condition beinr 6.5kW/tonne (9.0bhp/ton).

The six-speed plus splitter ZF box was well matched to th( engine, in fact so well matche( in the middle gears that on( wonders at DAF's reasonin( behind the use of the Fuller ir the eight-wheeler.

Although ZF makes this bo; in both synchromesh and con stant-mesh form, OAF specifie! the latter as it has proved to be far more robust in use.

One thing to watch with all DAFs using the ZF box is that the shift pattern is reversed with the lower gears being towards the driver and the higher gears away from him.

Complete with Wilcox body and all the Edbro bits and pieces, the FAT had a kerb weight of 8.38 tonnes (8 tons 5cwt) which gave it a potential payload capacity of just under 16 tons (four buckets).

It proved impractical to measure the fuel consumption at the various stages of the test, so we had to settle for an overall figure which included the empty run from DAF Trucks (GB) Ltd at Marlow, to the site and back again. Fuel consumption for the sixwheeler finally worked out at 42.8Iit /100km (6.6mpg). During its on-site test the FAT accounted for nearly 130 tons of sand in approximately one hour.

A fairly muddy loading area caused the six-wheeler some problems in grip both at the front and the rear. Even with the diff lock engaged, it was easy to get wheelspin on the top surface unless the driver was very, very careful indeed about how he fed the power in With mud and loose gravel on the twist,y route to the tipping area, the front wheels tended to plough on straight ahead when a change in direction was called for.

On the road, the FAT was as well behaved as we have come to expect from the Dutch-built trucks. From the driver's point of view, the comfort and comparative quiet of the cab were points in its favour.

Steering was very precise with none of the "woolliness" in the straight-ahead position that several trucks bave.

When cornering, the power steering was excellent while the geometry gave the FAT a turning circle of 16.8m (55ft).

The 14.5cu m (19cu yd) " body on the eight-wheeler plus the tipping gear resulted in a kerb weight of 10 tonnes (9 tons 17cwt) for the FAD 8x4. Therefore on road use at 30 tons gvw the potential payload capacity was just over 20 tons.

The main problem with the bigger DAF is getting to know the gearbox.

The first three gears are real "crawler" ratios; none of these got the truck moving fast enough to register on the tachograph.

With a bit of experimenting it was unnecessary to use these low gears on the site test, even when fully laden up the steeper parts. Starting from rest and pulling away from the shovel, fourth gear coped admirably.

Considering the extra 6 tons on board compared with the 6x4 with the same power output, no obvious difference could be felt from the driving seat.

Under exactly the same conditions as for the FAT, the eight-wheeler returned an overall fuel consumption of 50.51it/100km (5.6mpg). Owing to a mix-up at the loading area, the first two tips were carried out one bucket short, but during the test the eight-wheeler shifted over 150 tons of sand.

As both trucks use the same F218 tilt cab, remarks on engine accessibility apply equally to the FAT and FAD models.

The turbocharger is side mounted at the nearside of the engine and all the components on the scheduled maintenance list such as injectors and fuel pump are easy to reach.