A new Ford 2.4-litre

Page 23

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

diesel for the Transit, G bb Grace cE g DAuE. MIMechE

WHEN the Transit was first introduced in October 1965 it was offered with a Ford V-4 petrol engine or the Perkins 4.99 diesel. The 4.99 diesel was soon replaced by the bigger 4.108 but Ford recognized that diesel van performance would eventually have to be made more competitive — especially in the heavier versions — with similar-weight vans being manufactured in France, Germany and Italy; and the result of a planning decision taken then is the new 2.4-litre Ford diesel engine announced this week.

Four years' design and development work and an investment of /114rn was needed to produce Ford's new baby diesel. The new engine, designed and built to metric standards in Britain, is offered as an option to petrol engines in all Transit models built in the UK and Belgium. At Ford's Dagenham plant a new production line has been laid down and has an initial projected target of 30,000 units per year;. the potential annual output of the plant is some 90,000 engines.

This new diesel is considerably more powerful than the Perkins 4.108 diesel it replaces, but weighs only 771b more, so carrying capacity is hardly affected. Two performance ratings are offered and the high-rated version produces nearly 25 per cent more power and almost as great a gain in maximum torque over the 4.108.

This extra power gives the whole Transit range improved road performance. Acceleration and hill-climbing will naturally improve but because of the greater engine flexibility and the need for fewer gear changes, similar or even improved overall fuel consumption can be expected.

Two versions of the 2.4-litre engine are being built. The low-rated version develops 54 bhp net at 3600 rpm and 85 lb ft at 2500 rpm, both measured in accordance with BS AU 141: 1967. The high-rated version 'develops 61 bhp net at 3600 rpm and 95 lb ft at 2250 rpm, again to BS AU 141: 1967.

The 2.4-litre engine is physically small; very approximately it will fit a box 211 long by 2ft wide by 2ft 6in. high. In common with other Ford diesels the new engine uses a parent-bore construction — no wet liners — and this has the advantage of permitting maximum bore dimensions to be obtained within a given volume, while at the same time providing optimum bore cooling.

An unusual feature of the engine is that the centre-line of the cylinder block is inclined at 22÷cleg to the vertical and this means that, because of the cross-flow breathing layout, the intake manifold is on the centre-line of the engine and the exhaust manifold on the left-hand side. Also the exposed side carries the dipstick, electrics, injection, etc, while the hidden side has only the exhaust system. Although the engine is a high-speed unit by diesel standards — it is rated at 3600 rpm — piston speeds are lower at 2020ft /min than those of any competitive diesel.

The feature is achieved by adopting a large bore — 3.687in. short stroke — 3.37in. configuration. Owing partly to the high design speed and the likely legislation on smoke and oxides of nitrogen emissions an indirect-injection design was chosen using Ricardo Mark V B-type pre-combustion chambers.

Completely new engines are rare but this

engine is new from the sump up. By far the largest part of the engine — and that includes cylinder block, cylinder head, crankshaft, camshaft, connecting rods, front assembly, water pump parts of the valve gear and the sump — are built by Ford at Dagenham and designers worked closely with pattern makers and sandcasters to produce a trouble-free economical design.

The engine block — the largest casting extends down well below the crankshaft centre-line to ensure maximum rigidity but this feature in itself allows very simple sump and crank sealing. This means on the one hand that the crankcase can be fully sealed and thus comply with all known crankcase-emission legislation and on the other allow the use of a pressed steel sump which gives inherently good sound deadening qualities.

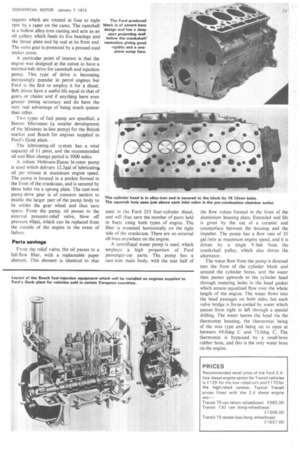

Intricate casting The cylinder head is a particularly intricate casting. Small precombustion chambers in the head are subject to intense heat and adequate coolant supply to these areas and to the valve bridges has been given detailed consideration. Eighteen cylinder-head bolts are arranged so that each cylinder bore has six bolts around it. It is interesting that a cylinder head gasket of a "non-retorque" type, ie once fitted it does not require further pulling down, has been especially developed. The gasket itself is very thin and has a wire-mesh centre which is relieved in places so as to achieve uniform loading of the gasket between bolts.

Ford pioneered modular cast iron crankshafts in the 105E Anglia and chose this method of production because it simplifies machining techniques and provides an excellent bearing surface without further treatment. The crankshaft runs in five large-diameter bearings; four bearings have a common 2.76in. diameter but the rear bearing is increased to 3.03in. to strengthen what could be a potential trouble-spot and to allow tapped holes for the flywheel mounting to run within the working length of the journal and thus reduce the overall length of the engine. Steel-backed Vandervell copper /lead and Glacier aluminium /tin crankshaft bearings are alternative specifications.

The connecting rods are steel forgings of H-section but the big-end bearing caps have a U-section to minimize weight. The Wellworthy aluminium alloy pistons are diamond-tuined to give an oil-retaining finish and are cut away and relieved at the sides to reduce weight. Three piston rings, two compression and one oil-control, are chromium plated and supplied by Perfect Circle, a French company.

Valve operation is by push rods and rockers. The push rods are short — only 6in. long — and carried in chilled cast-iron tappets which are rotated at four to eight rpm by a taper on the cams. The camshaft is a hollow alloy-iron casting and acts as an oil gallery which feeds its five bearings and the thrust plate and lip seal at its front end. The valve gear is protected by a pressed-steel rocker cover.

A particular point of interest is that the engine was designed at the outset to have a toothed-belt drive for camshaft and injection pump. This type of drive is becoming increasingly popular in petrol engines but Ford is the first to employ it for a diesel. Belt drives have a useful life equal to that of gears or chains and if anything have even greater timing accuracy and do have the very real advantage of being much quieter than either.

Two types of fuel pump are specified, a Simms Micromec (a smaller development of the Minimec in-line pump) for the British market and Bosch for engines supplied to Ford's Genk plant.

The lubricating-oil system has a total capacity of 11 pints, and the recommended oil and filter change period is 3000 miles.

A robust Hoboum-Eaton hi-rotor pump is used which delivers 12.3gal of lubricating, oil per minute at maximum engine speed. The pump is located in a pocket formed in the front of the crankcase, and is secured by three bolts via a sprung plate. The cast-iron pump-drive gear is of concave section to enable the larger part of the pump body to lie within the gear wheel and thus save space. From the pump, oil passes to the external pressure-relief valve, blow off pressure 60psi, which can be replaced from the outside of the engine in the event of failure.

Parts savings From alp relief valve, the oil passes to a full-flow filter, with a replaceable paper element. This element is identical to that used in the Ford 255 four-cylinder diesel, and will thus save the number of parts held in fleets using both types of engine. The filter is mounted horizontally on the right side of the crankcase. There are no external oil lines anywhere on the engine.

A centrifugal water pump is used, which employs a high proportion of Ford passenger-car parts. The pump has a cast-iron main body, with the rear half of the flow volute formed in the front of the aluminium housing plate. Extended seal life is given by the use of a ceramic seal counterface between the housing and the impeller. The pump has a flow rate of 35 gal /min at maximum engine speed, and it is driven by a single V-belt from the crankshaft pulley, which also drives the alternator.

The water flow from the pump is directed into the front of the cylinder block and around the cylinder bores, and the water then passes upwards to the cylinder head through metering holes in the head gasket which ensure equalized flow over the whole length of the engine. The water flows into the head passages on both sides, but each valve bridge is force-cooled by water which passes from right to left through a special drilling. The water leaves the head via the thermostat housing, the thermostat being of the wax type and being set to open at between 69.0deg C and 73.0deg C. The thermostat is bypassed by a small-bore rubber hose, and this is the only water hose on the engine.