Combining Two Types of Clutch

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

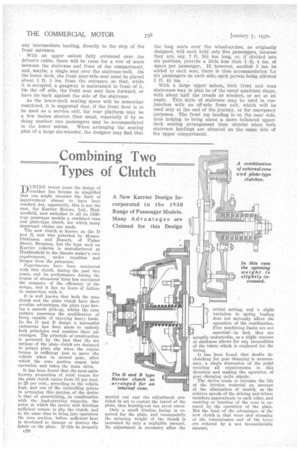

1/ URING recent years the design of clutches has become so simplified that one might consider the limit of improvement almost to have been reached, but, apparently, this is not the case, for Karrier Motors, Ltd., Fludtiersfield, now embodies in all its 1930type passenger models a combined cone and plate-type clutch, for which many important claims are made.

The new clutch is known as the D and B, and was patented by Messrs. Dickinson and Bassett, of Fisher Street, Swansea, but the type used on Karrier vehicles is manufactured at Huddersfield to the chassis maker's own requirements, under royalties and licence from the patentees.

Experiments have been conducted with this clutch, during the past two years, and its performance during the course of strenuous tests has convinced the company of the efficiency of the design, and it has no fears of failure in connection with it.

It is well known that both the cone clutch and the plate clutch have their peculiar advantages, the plate type having a smooth pick-up, whilst the cone pattern possesses the qualification of being capable of carrying heavy loads. In the D and B design a successful endeavour has been made to embody both principles and combine their advantages. The principle of construction is governed by the fact that the six springs of the plate clutch are designed to permit plate slip when the engine torque is sufficient just to move the vehicle when in second gear, after which the cone portion comes into operation and takes the main drive.

It has been found that the most satisfactory proportion of total torque for the plate clutch varies from 15 per cent. to 25 per cent., according to the vehicle load, and one of the controlling points in arranging this portion of the device is that of ascertaining, in combination with the load-carrying capacity, the point at which the power unit develops sufficient torque to slip the clutch, aud W.: the same time to bring into operation the cone portion, before sufficient heat is developed to damage or destroy the fabric on the plate. If this be properly carried out and the adjustment provided be set to curtail the travel of the plate, then burning-out can never occur.

Only a small friction facing is required for the plate, and consequently the spinning weight of the clutch is increased by only a negligible amount. No adjustment is necessary after the

initial setting, and a slight

variation in spring loading j does not seriously affect the

operation of the combination.

Fine machining limits are not

essential—in fact, they are actually undesirable' as a slight amount of slackness allows for any inequalities of the fabric which is employed for the facing.

It has been found that double declutching for gear changing is unnecessary, a single depression of the pedal covering all requirements in this direction and making the operation of gear changing quite simple.

The device tends to increase the life of the friction material on account of the elimination of snatch, as the relative speeds of the driving and driven members approximate to each other, and centring or location of the cone is ensured by the operation of the plate. Not the least of the advantages of the new clutch is that wear and stressing of the transmission and of the tyres are reduced by a not incousiderable amount. •