Modern Methods For Fine Wine Transport

Page 78

Page 79

Page 80

If you've noticed an error in this article please click here to report it so we can fix it.

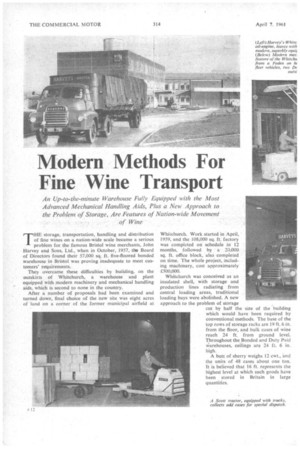

An Up-to-the-minute Warehouse Fully Equipped with the Most Advanced Mechanical Handling Aids, Pius a New Approach to the Problem of Storage, Are Features of Nation-wide Movement of Wine by G. Duncan Jewell

THE storage, transportation, handling and distribution of fine wines on a nation-wide scale became a serious problem for the famous Bristol wine merchants, John Harvey and Sons, Ltd., when in October, 1957, the Board of Directors found their 57.000 sq. ft. five-floored bonded warehouse in Bristol was proving inadequate to meet customers' requirements.

They overcame these difficulties by building, on the outskirts of Whitchurch, a warehouse and plant equipped with modern machinery and mechanical handling aids, which is second to none in the country.

After a number of proposals had been examined and turned down, final choice of the new site was eight acres of land on a corner of the former municipal airfield at Whitchurch. Work started in April, 1959, and the 108,000 sq. ft. factory was completed on schedule in 12 months, followed by • a 20.000 sq. ft. office block, also completed on time. The whole project, including machinery, cost approximately £500,000.

Whitchurch was conceived as an insulated shell, with storage and production lines radiating from central loading areas, traditional loading bays were abolished. A new approach to the problem of storage cut by half the size of the building which would . have been required by conventional methods. The base of the Lop rows of storage racks are 19 ft. 6 in. from the floor, and bulk cases of wine reach 24 ft. from ground level. Throughout the Bonded and Duty Paid Warehouses, ceilings are 24 ft. 6 in. high.

A butt of sherry weighs 12 cwt., 'and the units of 48 cases about one ton. It is believed that 16 ft. represents the highest level at which such goods have been stored in Britain in large quantities. The key to these operations was the development of new :.onstructional techniques and industrial handling by the lesigners, who had to consider matters peculiar to the wine :rade, for wine is extremely susceptible to alien odours and emperature changes. Consequently, Whitchurch is air:onditionedwith interior pressure slightly above that out:ide, to prevent obnoxious intrusions.

Use of the latest insulating techniques has given the warelouse rare thermal qualities and only one-tenth the power s needed to warm or cool the building that would be equired by conventional types. To avoid paint fumes, all urfaces are self-coloured, and light is kept to a minimum. rhe main production line is lit naturally by a glass-brick vall.

The cask store towers six rows high to the ceiling and here are four ranks of steel shelves with a capacity of 540 asks. The butts of sherry are constantly on the move to he storage tanks, making room for fresh supplies con

tinuously arriving from Spain. After gaining "landed age," wine is drawn from the tanks through glass pipes and filters to the production line, where it is bottled, labelled and sealed by modern machinery at a rate of 90 bottles per minute. There are two such production lines, and room for a third. At the end of the bottling lines, the filled bottles are repacked in the cases in which they arrived empty and are automatically sealed and weighed:

At this stage, Skid-Stac fork-lift trucks, the latest thing in mechanical handling, take over and remove them in cubic batches of 48 (12 bottles to a case), to the giant storage bays, one of which has a 140,000-case capacity and the other 45,000. These Skid-Stac trucks do not work on the usual pallet, as they are able to manipulate 1-ton loads on boards only a fraction of an inch thick. By this method a unit of 48 cases can be taken from ceiling level and neatly packed on a lorry for dispatch, within two minutes.

Provide Back Loads

This method of dispatching goods has had a beneficial effect on the economies of fleet operation; loading skids and pallets are returnable and, at 20 platforms to the ton, are expensive by hired haulage. They now provide back loads for Harvey's own long-distance vehicles.

All the Group's vans have special bodies, or are adapted for Skid-StaC loading, by means of false floors up to wheel box level, and have side entrances. Collis trucks are used where manhandling is required. and a Scott tractor, equipped with trucks, collects odd cases for special dispatch.

Lt.-Col. E. S. Cook is in sole Charge of transport, dispatch and distribution throughout the British Isles under the overall direction of Mr. A. M. McWatters, production and

transport director. There has been a 75 per cent. increase in the Group's own fleet since he joined Harvey's in the early 1950s.

Scheduled runs from Whitchurch for their own heavy vehicles include: London, three times weekly; Cardiff, three times monthly; Portsmouth, twice monthly; Manchester, twice monthly. There are also vans run to Bath and district weekly, and monthly to the Taunton area, Plymouth, South Devon, Salisbury Plain, Gloucester, Cheltenham and Torquay.

The fleet is split up between the various depots. At Whitchurch,there are 13 vehicles, including four articulated units, two of the tractors are Leyland Comets, one a Bedford with a Comet engine and the fourth a Dennis, all with Curimore trailers; seven ..of the remainder are vans and personnel carriers complete the total.

Fleet Distribution .

The depots are equipped mainly with vehicles for local distribution as follows: London, five vans and a personnel carrier; Birmingham, four vans and a personnel carrier; Kidderminster, one personnel carrier; Wolverhampton, one personnel carrier; Ipswich, two vans; Manchester, three vans and a personnel carrier; Glasgow, two vans and a personnel carrier; Portsmouth, two vans; Cardiff, two vans.

In addition to these 39 goods vehicles, Lt.-Col. Cook is responsible for 48 private cars and a small bus. The vans are Mainly of Morris, Bedford and Austin makes. All maintenance outside Bristol is done by local garages and servicing is on a regular basis, at 1,000-mile intervals. Replacement is considered as soon as normal running becomes expensive. Four mechanics are employed at Whitchurch.

In 1960, sub-contracting payments were 160,000, out of a total haulage cost of 04,000. Ninety-five per cent. of long-distance work is done by hired transport, including all Scottish deliveries. Quotations for transport are sought half-yearly, and the work is given out on the basis of the best rate commensurate with service.

British Railways or British Road Services are used for the majority of smalls to all depots, but orders for three bottles or under are sent by post. Business is mainly wholesale although there are still a small number of old-established retail customers who insist on direct dealings.

New Warehouses

New warehouses have been built at Birmingham, Glasgow, London and Manchester where Skid-Stac loading is also practised. Portsmouth and Cardiff depots have oldtype cellar storage with conveyor-belt systems from ground level, but in view of the steady expansion irt trade, plans are in hand for the development of new premises at these points also. Kidderminster and Wolverhampton are subsidiaries of the Birmingham depot, and Ipswich is in the hands of an associated company, Sidgwick and Cowell, Ltd.

All forward distribution to depots is from Bristol and large orders are sent direct to Customers. Wines and spirits dispatched in 1960 amounted to more than 11,000 tons, which included 450,000 cases for the home market and 150,000 cases for export. Dispatches average about four 10-ton loads per working day, but there is a 50 per cent. increase during the October-December peak.

Stocks .are held at depots ready for distribution and normal storage is as follows: London, 20,000 cases (350 tons); Manchester, 26,000 cases (460 tons); Glasgow, 21,000 cases (365 tons); Portsmouth, 7,500 cases (135 tons); Cardiff, 5,000 cases (90 tons); Birmingham, 28,000 cases (500 tons). Each depot is responsible for its own distribution within a radius of approximately 50 miles.

Inward traffic in 1960 amounted to 12,000 casks (1,400 tons) of wine, and 30,000 cases (500 tons) of branded wines D I 4

and spirits. There were also60,000 gross of new bottles— no second-hand bottles are used.

Because of its isolated position, the Whitchurch factory bus service, to and from Bristol, for the 364 employees hal to be provided by contract. Harvey's hire three buses ir each direction, morning and evening, five days a week from Bristol Omnibus Co., Ltd. They also provide a lunch-time shopping service for female employees or Tuesdays and Thursdays.

Wine has been shipped into Bristol since Anglo-Saxor times, and it is recorded that two centuries ago, casks a wine travelled from the quayside to merchants' cellars or rough wooden sledges dragged through the streets by team: of two or three horses.

Harvey's themselves have been established in the wim trade for more than 160 years and haveseen the Cit] give its name to two of their finest sherries, " Bristol Milk' and "Bristol Cream."

Among the great wine cellars built around the time of th, Norman Conquest was that of the monastery of Si Augustine on the banks of the river Frome, bordering th• ancient city. Harvey's premises in Denmark Street are ii this area, and it was probably the ancient vaults of th monks, which were purchased by their founder, Willian Perry, in 1796.

Descended from Sea Captains The Harveys are descended from two sea captains, th son, Thomas Harvey, marrying Anne Urch, sister of Perry' junior partner, and the concern later became a Harve family partnership. A limited liability company was forme in 1893, with John Harvey II as chairman.

Their initial export order was to Mombasa in 1884, an the company now export to virtually every market open t importation of liquor, their United States market alon having increased by 25 per cent. in the last few year: Harvey's also pioneered mechanical bottling and bought th first labelling machine.

They suffered severely in the Second World War, th Denmark Street offices being destroyed by enemy action i 1940. Temporary quarters were taken in Pipe Lane an despite a wine famine—Bristol handled 9,500 tons in 194 but only 50 tons in 1942—Harvey's emerged, undeterred E the end of hostilities. Happily, their ancient Denmark Strei cellars remained unscathed and the company's head offic was reconstructed on this site in 1953. The business rapidl built up again and Mr. G. E. McWatters, whose moth{ was a Harvey, became chairman in 1956. In 1958, whe plans for expansion were ready, they became a publ company.

Agreements with Spanish associates who own the world biggest Sherry Bodega, ensure Harvey's supplies from Jen and give them control of stocks up to 47,000 butts. l Oporto they have connections with the famous Port wir firm, Cockburn Smithes, Ltd.

Fork-lifts in Cellars

Not the least notable feature of the Whitchurch proje is that the " cellars " are above ground in a unique him wine store. There tables wines, both Harvey's own bottlit and those bought in bottle from France, are stored fi maturing in bays, on three levels of rigid steel, with acce by fork-lift trucks and trolleys. Bottles are individual binned by hand and there is a capacity of 200,000 dozi bottles.

Whitchurch has a production capacity of lm. don bottles of fortified wines annually, with another 50,01 dozen of table wines, and their smooth transportation ai distribution is a triumph for the project's designers and tl transport department.