HINTS ON MAINTENANCE.

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

613.—An Adjustment for the Clutch Brake the. A.E.C.

OUT sketch shows a simple method of providing a means of adjustment for the clutch brake of a standard A.E.C.

In practice, it is often found that the spring fitted on the brake operating rod is rather weak, so preventing the fine adjustment which is essential; in fact, it is often necessary, in order to ensure the clutch stopping in a satisfactory manner, to adjust the rod at the front end to such an extent that the clutch brake is slightly on all the time, but this soon wears away the Ferodo lining, besides throwing extra work on the engine.

By 'the simple method of removing the fixed nut at the rear end of the rod, screwing the rod for a further 11 ins, along its length and fitting locknuts, the spring can be so adjusted as to give a very effective and positive stop. Care must, of 'course, be taken effectively to lock the nuts so as to ensure that slacking back will not occur.

614.—Annealing Steam-wagon Components

There is quite a number of parts in connection with steam-wagon chassis which require annealing occasionally. The chief of these are boiler tubes, steering chains and copper pipes, and if more attention were given to the importance of this treatment, at fairly frequent intervals, fewer breakdowns would occur and the parts would last considerably longer.

The correct method of annealing boiler tubes and steering chains is to place them inside a furnace and to heat until blood red, allowing them to cool down inside the furnace.

If a furnace be not available, boiler tubes can be • annealed in an open fire in the following manner. Heat each end of the tube for a distance of about 6 ins, until blood red and allow these ends to cool down as gradually as possible, keeping in mind that the longer taken in the cooling the more effective will be the annealing.

With copper pipes, the work must be carried out in an entirely different manner, as they must be heated to blood red and then plunged into cold water.

622

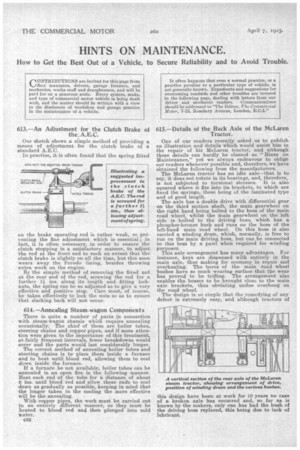

of 615.—Details of the Back Axle of the McLaren Tractor.

One of our readers recently asked us to publish an illustration and details Which would assist him in the repair of his McLaren tractor, and although these details can hardly be classed as " Hints on Maintenance," yet we always endeavour to oblige our readers whenever possible and, therefore, we have obtained the following from the manufacturers. The McLaren tractor has an idle axle—that is to say, it does not rotate in its bearings, and, therefore, is not subjected to torsional stresses. It is also squared where it fits into its brackets, to which are fixed the springs,these being of the laminated type and of good length.

The axle has a double drive with differential gear on the third motion shaft, the main gearwheel on

the right hand being bolted to the boss of the main road wheel, whilst the main gearwheel on the left side is bolted to the driving boss, which has a. phosphor-bronze bush and runs on the boss of the left-hand main road wheel. On this boss is also carried a winding drum, which, normally, is free to run on the main driving boss, but can be connected to this boss by a pawl when required for winding purposes. This axle arrangement has many advantages. For instance, keys are dispensed with entirely in the main axle, thus making for economy in repair and overhauling. The bores of the main road wheel bushes have so much wearing surface that the wear has proved to be trifling. The arrangement also enables the bosses to be brought close to the main axle brackets, thus obviating undue overhang on the road wheel.

The design is so simple that the remedying of any defect is extremely easy, and although tractors of this design have been at work for 10 years no case of a broken axle has occurred and, so far as is known by the makers, only one has had the bush of the driving boss replaced, this being due to lack of lubricant.