A CAM-OPERATED STEERING GEAR.

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

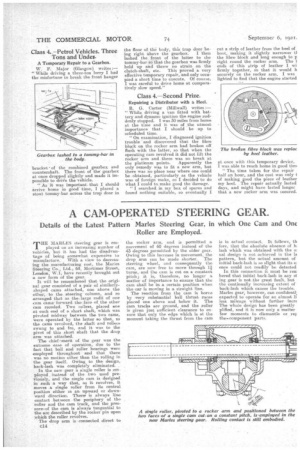

Details of the Latest Pattern Manes Steering Gear, in which One Cam and One Roller are Employed.

THE MARLES steering gear is employed on an increasing number of vehicles, but it has had the disadvantage of being some-what expensive to manufacture. With a view to decreasing the manufacturing cost, the Manes Steering Co., Ltd., 64, Mortimer Street, London, W.1, have recently brought out a new form of the gear.

It will be remembered that the origiMt1 gear consisted of a pair of similarlyshaped cams attached, one above the other, to the steering column, and so arranged that as the-large radii of one cam came forward the. face of the other cam receded. Two rolleas, placed sue at each end of a short shaft, which was pivoted midway between the two cams, were operated by the latter so that, as the cams revolved, the shaft and roliera swung to and fro, and it was to the pivot of this short shaft that the drop arm was attached.

The chiebanerit of the gear was the extreme ease of operation, due to the fact that hall and roller bearings were employed throughout and that there was no motion other than the rolling in the gear itself. Owing to thedesign, back-lash was completely eliminated. . In the new. gear a single roller is employed instead of the two used previously, and the single cam is designed in such a way that, as it revolves, it moves .a single roller from its central position either in an upwaad or downward direction. There is always line contact between the periphery of the roller arid the cam track, and the prossurei of the cam is always tangential to the arc described by the rocker pin upon which the roller revolves.

The drop arra is -connected direct to C14

the rocker arm, and is permitted a movement of 60 degrees instead of the 43 degrees permitted by the older gear. Owing to this increase in movement, the drop arm can be made shorter. The steering wheel, and consequently the cam, are now free to move through 11, turns,• and the cam is cut on a constant pitch; it is, therefore, no longer a matter of importance to ensure that the cam shall be in a certain position when the car is moving in a straight line.

The reaction from the cam is borne by ;very substantial ball thrust races placed one above and below it. The cam tracks are ground, and the roller is given just 'sufficient clearance to ensure that only the edge which is at the moment taking the thrust from the cam is in actual contact. It follows, th fore, that the absolute absence of b; lash which was obtained with the a nal design is not achieved in the la pattern, but the actual amount of initial back-lash is so slight that its e: ence could not readily be detected In this connection it must be rear bered that initial back-lash in any at big gear is not the great fault, but the continually increasing extent of back-lash which causes the trouble. Manes gear, however, can confidentl; expected to operate for an almost li less mileage without further iners The whole design has been greatly plified, and it is now only a matter few moments to dismantle or rep theecomponent parts.