• If you want performance and long life from your

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

truck tyres, take a tip from the manufacturers and maintain them properly. Doing so will save your money, protect your reputation and is, as Sir Robert Mark used to say, a major contribution to road safety.

There are over 2,500 depots in the National Tyre Distributors Association alone. If they are all as busy as the 500 Associated Tyre Services depots, which on average attend a breakdown call every three minutes, there are a staggering 1.2 million calls for assistance following tyre failure every year.

That represents an enormous burden to the fleet operator, trying to run a profitable operation on a tight budget.

Most of these distress calls are selfinflicted, say the makers, and arise from bad maintenance or neglect. SP Tyres, for example, warns that a tyre's service life can be reduced by as much as 30% from causes such as under inflation (15%), overloading (8.0%) and speeding (7.0%). This obviously boosts tyre costs to the extent that the heaviest artic operator may well be throwing away nearly £2,000 a year for every vehicle in its fleet. It may come as a relief to hear that one of the essential ingredients for keeping your tyres in the right condition for optimum performance and longevity is as free as. ..air.

Air carries the weight of the truck and its load, and a tyre derives its capacity to carry that load through the pressure within it: a specific pressure for a specific load. Under inflation will start an irreversible process of deterioration.

CONSIDERABLE NEGLECT

The inner tyres on driven and trailer axles are victims of considerable neglect, largely because they are awkward to reach for checking and inflation. The underinflated member of a pair scrubs out, while the correctly adjusted one carries extra load, suffers greater deflection and many fail prematurely through overheating.

An easy way to avoid this situation, particularly where rental vehicles are concerned, is to extend the valve stems of the inners, making it easy to balance the pressures.

Avon Tyres service manager Derek Trigg quantifies the problem: a 20% drop in pressure raises tyre costs by 25%. An overload of 10% reduces tyre life by 20%. In our Workshop conference, held earlier this month, John Ballinger, who heads Michelin's technical department, pointed out driver-related factors which affect tyre wear, including cornering, driving and braking forces, which create abrasion.

Whereas in normal circumstances a tyre may last up to 120,000km, locked-wheel braking can scrub off 15nun of tread in a few hundred metres. Braking can affect tyres in more ways than any other vehicle or driving factor, says Ballinger.

In serious cases of poor shoe adjustment or erratic driving behaviour, the tyre beads are subjected to high temperatures which can affect subsequent retreading.

In the worst cases he says, they can simply explode as the casing wires unwrap from the bead wire. This is fairly rare on 20 or 22.5 tyres but, warns Ballinger, is not uncommon on 15in tubed trailer tyres.

Fortunately such explosions usually happen when the vehicle is stationary, when extra heat is passed to the tyre by the close proximity of the wheel and drum.

Tyres generate longitudinal and lateral forces to drive, brake and steer a vehicle, so excesses in any of these areas will probably damage them. Wheel or axle misalignment, particularly on driving bogies or trailers, will cause sloping or irregular tread wear and could result in a GV9 ticket.

Trigg also advises transport managers to carry out regular wheel-alignment checks, especially if tyres are showing signs of heavy shoulder wear. Many semitrailers run out of alignment from their tractive units, leading to rapid abrasion of the trailer-bogie tyres and irregular "tramline" wear of the front steering-axle tyres.

Manufacturers also stress the harm caused by over inflation, particularly on drive axles.

For example, a tri-mded tractive unit pulling 36 or 38 tonnes may only have about 8.0 tonnes on its drive axle. With its 11 or 12k 22.5's inflated to 7 or 7.5 bar (100-110psi) the effect on tyre life, says Ballinger, can be disastrous. As a rule, slight over inflation on steering axles and the correct pressures on fully-laden drive axles will maximise tyre life.

Chronic over inflation, however, increases tread wear, affects traction on gradients and threatens the integrity of the tyre's structure, especially on sustained motorway work or over rough ground.

Overloading also places excessive strain on tyres, leading to greater deflection and overheating, which results in rapid wear. It also makes them more susceptible to impact damage and premature failure.

SP Tyres points out that where tyres are used in a twin-wheel configuration they should be properly matched for diameters — something that cannot always be guaranteed with less-familiar imported brands. For this reason care should also be taken when pairing part-worn tyres with regrooved ones. Despite apparently identical tread depths, tyre diameters will be different in this case, and could vary by as much as 17mm. They should be measured first, and only those with differences of lOrnm or less should be paired up.

Buying cheap imported brands that originate in the Far East, Middle East and certain Eastern European countries may give short-term savings, but some of the more obscure brands have insufficient rubber to allow for regrooving. Casings may not have a good trade-in value either.

Maintaining tyres is a relatively inexpensive task that takes only a few minutes per vehicle. Most tyre distributors and service agents will include it in their maintenance agreements.

There are many simple tips for looking after your tyres (besides checking the air in them), such as removing stones and chippings from the tread; discouraging the painting of valve stems; keeping the valve-stem threads clean, and, of course using dust caps.

Many tyre manufacturers believe that transport managers should look at the economics of employing someone full time to oversee tyre care. In a medium-sized fleet, the cost of adding just one fitter to its workforce could easily be recouped by savings in tyre replacement.

HIDDEN BENEFITS

There are hidden benefits too, such as reduced downtime, and fewer problems with delivery schedules.

In Britain, most CV tyre replacements are as a result of under inflation and overloading. Tubed tyres are 10 times more likely than tubeless to suffer from under inflation and run-flat damage.

Ballinger also stresses that fitting standards need to be monitored, and that operators should check the quality of the tubes and flaps supplied.

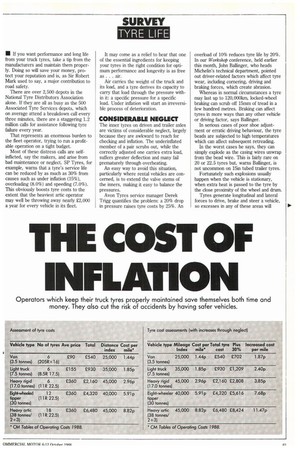

Tyre costs per kilometer fails to take into account poor driving, traffic or offroad conditions. According to our Tables of Operating Costs, they vary as a percentage of the total running costs from 5.0% for a 4.5-tonne load carrier to 10% with a 38-tonne artic. One thing is dear, however; specific tyre maintenance can save up to £2,000 per vehicle per year in real terms — and with today's high replacement costs, that is not to be ignored.

by Bryan Jarvis