BODYWORK REPAIRS

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

MADE EASY

A Useful Contribution from Our Bodybuilding Expert which Explains the Various Operations in Repairing Damaged Coachwork. How to Remove a Body from a Chassis

I N the modern commercial vehicle the various parts are designed, materials selected and processes adopted to ensure that the inevitable wear is slow and gradual, and is such as may be rectified as part of the normal maintenance operations.

Structural defects are still met with, although they occur less frequently as a result of the improvements made in design and construction.. However, it is impossible to inspect every inch of material, or every detail of the structure, as it proceeds towards completion. Moreover, no branch of the motor industry has evolved so rapidly as that of the building of coach and bus bodywork, consequently there is much experiment with new designs which may not be entirely successful so far as the earlier examples are concerned.

Wear and structural defects may be combated by devising remedies based on the experience gained. But when damage arises through an accident the chief problem is to find the most economical method of repair.

Nevertheless, the designer may use such opportunities for inventing better means for protecting the bodywork so that injury is mini

mized, or arrange the construction so that repair is facilitated.

Much minor damage to the panelling is prevented by fitting bumpers at the back and using protecting rails and steps at the sides of the body. Repairs are easier if exterior panelling be in regular sections and secured by simple devices, whilst seats and windows should be designed for quick removal and interior panelling eliminated wherever possible,

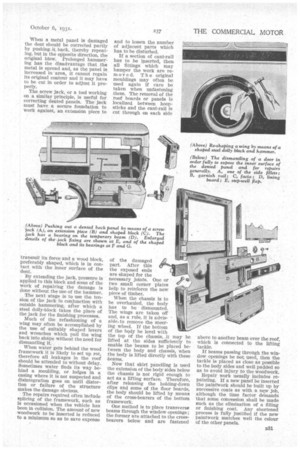

When a metal panel Is daniaged the dent should be corrected partly by pushing it back, thereby repeating, but in the opposite direction, the original blow. Prolonged hammering has the disadvantage that the metal is spread and, as the panel is increased in area, it cannot regain its original contour and it may have to be cut in order to adjust it properly.

The screw jack, or a tool working on a similar principle, is useful for correcting dented panels. The jack must have a secure foundation to work against, an extension piece to

transmit its force and a wood block, preferably shaped, which is in contact with the inner surface of the dent.

By extending the jack, pressure is applied to this block and some of the work of repairing the damage is done without the use of the hammer.

The next stage is to use the tension of the jack in conjunction with outside hammering, after which a steel dolly-block takes the place of the jack for the finishing processes.

Much of the refashioning of a wing may often be accomplished by the use of suitably shaped levers and wrenches which pull the wing back into shape without the need for dismantling it.

When water gets behind the wood framework it is likely to set up rot, therefore all leakages in the roof should be attended to without delay. Sometimes water finds its way behind a moulding, or lodges in a casing where it is not suspected and disintegration goes on until distortion or failure of the structure makes the damage obvious.

The repairs required often include splicing of the framework, such as is occasioned when the vehicle has been in collision. The amount of new woodwork to be inserted is reduced to a minimum so as to save expense and to lessen the number of adjacent parts which has to be disturbed.

If a section of cant-rail has to be inserted, then all fittings which may hamper the work are remove d. The original mouldings may often be used again if care be taken when unfastening them. The removal of the roof boards or panels is localized between hoop sticks and the cant-rail is cut through on each side of the damaged part. After this the exposed ends are shaped for the necessary joints. One or two small corner plates help to reinforce the new piece of timber.

When the chassis is to be overhauled, the body has to be dismounted. The wings are taken off and, as a rule, it is advisable, to remove the steering wheel. If the bottom of the bedy be level with the top of the chassis, it may be lifted at the sides sufficiently to enable the beams to be placed between the body and chassis, when the body is lifted directly with these beams.

Now that skirt panelling is used the extension of the body sides below the chassis is not rigid• enough to act as a lifting surface. Therefore, after releasing the holding-down clips and some. of the floor boards, the body should be lifted by means of the cross-bearers of the bottom framework.

One method is to place transverse beams through the window openings ; the former are attached to the crossbearers below and are fastened above to another beam over the roof, which is connected to the lifting tackle.

If beams passing through the window openings be not used, then the tackle is placed as close as possible to the body sides and well padded so as to avoid injury to the woodwork, Repair work usually includes repainting. If a new panel be inserted the paintWork should be built up by successive coats as with a nqw job, although the time factor demands that sonic concession shall be made such as the elimination of a filling or finishing coat. Any shortened process is fully justified if the new paintwork matches well the colour of the other panels.