Cool ideas in cold storage

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

by Steve Banner • Marshall Thermo King's annual reefer van and truck display at its Cambridge base featured the first Dennis Eagle Elite-based aircraft catering vehicle to join Air Canada's fleet. Equipped with a highreach refrigerated body by Hullbased bodybuilder Paneltex, the 17-tonne„5.4m-wheelbase Elite chassis is the first of four to enter service at Heathrow Airport to deliver supplies to airliner galleys.

Telehoist gear raises the body to heights between 2.25 and 6.0m. Internally the box is 7,11m long, 2.37m wide and 2.21m high, with wide-slat shutter doors at each end. Paneltex acquired the rights to this and other designs when the oldestablished Solihull bodybuilder Wilsdon closed last year.

Not surprisingly the Dennis was fitted with Thermo King SD-1750 refrigeration equipment but later versions will have SD-II Max units.

The event also promoted two new fridge units: the SMX Tel dual-temperature nose-mount system for 33-Euro-pallet 13,6m trailers; and the V-250 unit for lightweight rigids. Both models were on display at the Institute of Road Transport Engineers' show at Telford in May.

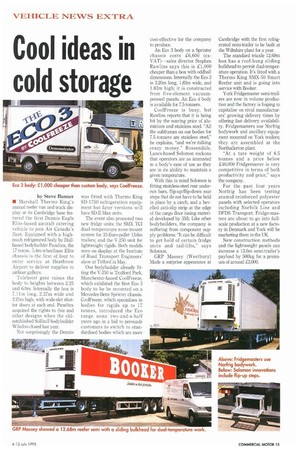

One bodybuilder already fitting the V-250 is Trafford Park, Manchester-based CoolFreeze, which exhibited the first Eco 3 body to be be mounted on a Mercedes-Benz Sprinter chassis. CoolFreeze, which specialises in bodies for rigids up to 17 tonnes, introduced the Eco range some two-and-a-half years ago in a bid to persuade customers to switch to standardised bodies which are more cost-effective for the company to produce.

An Eco 3 body on a Sprinter chassis costs £6,600 (exVAT)—sales director Stephen Rawlins says this is £1,000 cheaper than a box with oddball dimensions. Internally the Eco 3 is 3.20m long, 1.83m wide, and 1.83m high; it is constructed from five-element vacuumpressed panels. An Eco 4 body is available for 7.5-tonners.

CoolFreeze is busy, but Rawlins reports that it is being hit by the soaring price of aluminium and stainless steel. All the subframes on our bodies for 7.5 tonners are stainless steel," he explains, "and we're talking crazy money." Rossendale, Lancs-based Solomon reckons that operators are as interested in a body's ease of use as they are in its ability to maintain a given temperature.

With this in mind Solomon is fitting stainless-steel rear underrun bars, flip-up/flip-down rear steps that do not have to be held in place by a catch, and a bevelled anti-slip strip at the edge of the cargo floor (using material developed by 3M). Like other bodybuilders, the company is suffering from component supply problems; "It can be difficult to get hold of certain fridge units and tail-lifts," says Solomon.

CRP Massey (Westbury) Made a surprise appearance at Cambridge with the first refrigerated semi-trailer to be built at the Wiltshire plant for a year.

The standard triaxle 12.68m box has a roof-hung sliding bulkhead to permit dual-temperature operation. It's fitted with a Thermo King SMX-50 Smart Reefer unit and is going into service with Booker.

York Fridgemaster semi-trailers are now in volume production and the factory is hoping to capitalise on rival manufacturers' growing delivery times by offering fast delivery availability. Fridgemasters use Norfrig bodywork and ancillary equipment mounted on York trailers; they are assembled at the Northallerton plant.

"At a tare weight of 8.5 tonnes and a price below £40,000 Fridgem aster is very competitive in terms of both productivity and price," says the company.

For the past four years Norfrig has been testing aramid-reinforced polyester panels with selected operators including Norfolk Line and DFDS Transport. Fridge-masters are about to go into fullscale production at a new factory in Denmark and York will be marketing them in the UK.

New construction methods and the lightweight panels can increase a 13.6m semi-trailer's payload by 500kg for a premium of around £2,000.