Operator-inspired bodies save time and labour

Page 67

Page 68

Page 69

Page 70

If you've noticed an error in this article please click here to report it so we can fix it.

Making the best use of cubic capacity in terms of loadability and load storage is a common challenge to bodybuilders that typically requires close co-operation with the operator by Paul Brockington

BALANCING the cost and operational benefits of having bodies and equipment designed to cut turn-round time is relatively simple in the case of heavy vehicles making regular journeys on distance work but the choice is much more complex when one is considering vehicles and equipment for multi-drop delivery work. This is especially true if there are variations in the types of load carried and /or it is necessary to pre-load in a certain way to suit the unloading pattern.

Side openings of the right type in the right place, the form of rear opening, box dimensions tailored to the load, methods of securing the load, the existence or absence of wheel arches and so on can have a big influence on loadability.

In many cases an operator will prefer to have a standard body that can be altered or equipped to cater for his needs without high weight, cost and payload penalties, to one that is custom-built. While devices such as tail-lifts, floor tracks and so on are often important aids to easy loading, in this article they are considered

as part of the body /equipment "structure" devised to make the most of advantages in loadability.

Access both sides

The outcome of close co-operation between the operator, Proctor and Gamble Ltd, and the bodybuilder, Boalloy Ltd of West Heath, Congleton, Cheshire, the Linkliner body has sliding doors that provide complete accessibility from both sides. The forward sliding door is equippdd with a hinged leaf door that can be used in the unlikely event of the load shifting in transit and jamming the sides to manipulate the load. A roller shutter is fitted at the rear.

The body is said to have reduced loading time by fork-lift truck from 45min to 15min. Deliveries are mainly to retail outlets and accessibility is of first importance to order picking at the kerbside. Unloading is facilitated by construction of the doors in lightweight glass-fibre sandwich which is capped with aluminium along the edges. And as an aid to order assembly, a floor

level side platform is available which folds down along the side of the vehicle when not required. About 80 Linkliners are employed by the operator.

Linkliner bodies have also been adopted by Geest Ltd of Spalding for the distribution of produce from Holland to retail outlets in this country. Geest report that use of the bodies has materially reduced damage to flowers, fruit and so on.

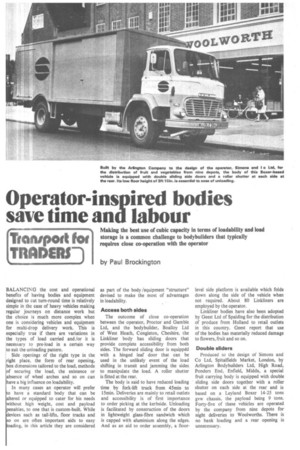

Double sliders Produced to the design of Simons and Co Ltd, Spitalfields Market, London, by Arlington Bodybuilders Ltd, High Road, Ponders End, Enfield, Middx, a special fruit carrying body is equipped with double sliding side doors together with a roller shutter on each side at the rear and is based on a Leyland Boxer 14-25 tons gvw chassis, the payload being 9 tons. Forty-five of these vehicles are operated by the company from nine depots for night deliveries to Woolworths. There is no bank loading and a rear opening is unnecessary. It is not practical to load soft fruits to a height of more than a few feet and ease of unloading from the pavement is essential. The bodies are therefore long (22ft 6in.) and low, the deck height being 3ft 10in. And the driver can reach into the body to pick a load without entering it, transhipment being made to lockable cages outside the shops manually or, in some cases, with the aid of a trolley.

Such is the nature of the loads that loading by fork-lift truck onto the floor of the vehicle is not possible. But a truck is used to carry the produce to the vehicle and acts as a loading platform.

A max-cap approach

Designed to eliminate "any odd corners to ensure maximum use of cubic capacity and for easy operation in crowded circumstances" the latest van body produced by Marshall of Cambridge (Engineering) Ltd, Airport Works, Cambridge, CB5 8RX for Curry's Ltd incorporates a nylon roller shutter at the front on the side of the vehicle appropriate to the location of shops to which deliveries are made on the normal route. If the shops are on the right-hand side of one-way streets the shutter is incorporated on the offside; in either case it is employed in conjunction with roller shutters at the rear, a Ratcliff 5cwt tail-lift being fitted at the rear or to a side opening as required.

A load typically comprises square-shaped washing machines, refrigerators, deep freezers and so on, a hinged shelf being provided for the carriage of smaller items, such as transistor radios and record players; straps of webbing are used to secure the loads in transit. The filler neck of the fuel tank has been repositioned to project through the front of the body and thus avoid waste of internal space.

Drink to it I When Frank Hobbs of Frank S. Hobbs (London) Ltd required a vehicle to collect and deliver the household furniture and personal effects of American servicemen in special boxes he approached Imperial Coachbuilders (Basildon) Ltd, Basildon, Essex, who were later rewarded — after the company had produced a suitable body on a Bedford KDL chassis — with the comment by a senior master sargeant that the vehicle was "the greatest thing since Coca Cola"!

The 20ft 6in. body has four apertures on the left side with a width of 4ft bin, and these are closed by up-and-over light-alloy spring-loaded roller shutters. The sides are fitted with a panel of mild steel to withstand bumps when loaded by fork-lift trucks. Four equidistant tying battens of top-hat aluminium section run the full length of each side and across the front, the sections being detachable in the area of the apertures. Two half doors at the rear are designed to be flush with the sides when open, each door having a cam-action fastener.

Gravity rolling Exploiting the advantage of a maximumcapacity articulated van body to provide easy loading with relatively simple modifications is an achievement that can be claimed by the York Trailer company in the development of a Freightmaster van to cater for the special requirements of Express Dairy (Northern) Ltd, namely to carry an 18-ton load of 24 43in. x 37in. pallets designed for the application. The Freightmasters are equipped with Hands Neway rolling-lobe air suspension that is employed in conjunction with two rows of roller tracks to enable the pallets to be moved by gravity from the rear to the front or vice versa, the necessary tilt being obtained by regulating the pressure in the air springs. Each pallet is fitted with a base frame having a pair of skids. On-loading 24 pallets occupies less than 15min and unloading is completed in approximately the same time. Transverse levelling valves in the air suspension system compensate for asymmetric loading of the trailers.

Perimeter-framed boxes

A form of construction that facilitates the provision of extra door openings and variation of rear openings has obvious advantages in catering for the loading requirements of customers individually. Th Strongbox pillarless bodies, made by H. Tidd and Son Ltd, Marston Road Industri Estate, St. Neots, Hunts, come into thi category, their basic structure comprisin an aluminium perimeter frame, which i combined with one-piece side and fron panels of plywood bonded on each sid to a layer of grp.

Examples include Post Office parcel vans, based on Ford D0607 diesel-engined chassis, which having an interior length of 14ft and a height of and width of 6ft 3in. and 6ft 6in. respectively. The body incorporates a sliding door on the left to give an opening at the front, while two half-width rear doors are located above a 2ft high tailboard. The laden weight of the van is under 2 tons 19 cwt.

A Strongbox-bodied BLMC Boxer, supplied to Geest Industries Ltd for carrying bananas and fresh market-garden produce to wholesalers and collecting produce from growers, has a 6ft 6in.-wide opening at the front on each side which is closed by a roller shutter and a 2ft high drop-side having a toe aperture that is closed by a sliding plate. An under-run bumper can be used as a step to facilitate access to the interior through rear-mounted roller shutters. The suitability of a body for pallet loading is frequently of major importance to the operator notably if the pallets are of a standard type. In the case of a Strongbox 4011 semi-trailer van body an internal width of over 8ft 24.in. and enables 40m. x 48in. pallets to be loaded in two rows transversely in the body, which increases the number of pallets that can be carried to 24 compared with a total of 22 if they were carried in a narrower body that necessitated one row being placed on the floor lengthways.

For crane loading, too Options offered by Clarke Equipment Ltd (Trailer Division), Bridgend, Glamorgan, for the company's range of Cargo Vans cover a wide variety of door openings, and an open top designed to cater for crane loading, while a thinwall body gives a rear opening that is +in. less than the internal width. Side-door . options include a single 3ft wide or 5ft 10in, double door and roll-up doors up to 8ft, and there are five types of rear door. These comprise a top-hinged type (which is particularly suitable for bakery vans) a standard double opening hinged door, and doors providing a narrow single centre, a double narrow centre, a three-leaf full-opening and a four-leaf full-opening. A Clarke roller shutter has an oscillating top shaft which enables the top clearance when closed to be reduced to a minimum, and an under-roof shutter is available. The standard double-opening hinged door is of the slam-lock type that is equipped with locking barrels in the interests of security.

The open-top body (the Series 300) features special top rails that accept detachable roof bows, the top header being hinged to permit it to be swung away from either side for crane loading. In the case of the thinwall unit (the Series 400) a rear opening of 7ft 11+in. gives access to an interior of 8ft. And for deliveries on which washing out is essential to hygiene and time saved is important to overall vehicle utilization, reinforced plywood construction with panels that are gel-coated with woven glass (of the Series 500) has obvious benefits. It is notable that the range of options is applicable to the Series 200 under-3-ton bodies.

No sheeting needed Full-length side loading without any bother with sheeting and roping is provided by the Hustler curtain-sided bodies produced by Southfields Coachworks Ltd, Bakewell Road, Loughborough, which can be built on any chassis, rigid or articulated. It is particularly suitable for pallet loading and is available in lengths of 2411 to 40ft. The weight of a 4011 body is 14 cwt.

Southfields point out that loading in areas of heavy traffic and one-way streets typically increases the advantages of eitherside loading over the entire length of the vehicle, particularly if the sides can be quickly uncovered and closed up.

The pvc-coated polyester curtains of the Hustler are tensioned with Loadlok buckles of a new type and are said to be immune from stretching over a temperature range of 100 deg F. Attached at 2ft 6in. centres to the vehicle chassis, the nylon webbing of the buckles hook on curl plates fastened to reinforced strips of the curtains. A one-piece glass-fibre laminate roof is attached to the cant-rail frame with aircraft type Jo bolts that are claimed to obviate tearing of the material.