Why diesel additives add up...

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

OPERATORS are always concerned with the economy of their operation and can usually be relied upon to be well up in the latest methods of fuel saving. Most of the techniques used in recent years — radial tyres and wind deflectors for example — are familiar to operators, but what about a fuel additive?

Although accepted in the lube oil field, additives are not so well known as far as dery is concerned.

CM has been talking to Barry Lewis of Chalbar — manufacturer of Econsol Auto D — about what exactly an additive is and how an operator can use one to improve fuel consumption and cut down on black smoke.

The fuel oil used in diesel engines is produced as part of the fractional distillation of crude petroleum. This was laid down by nature during the carboniferous period over 160,000,000 years ago and is the result of geologically changing patterns of pressure and temperature on tree-ferns and other vegetable matter fossilised over aeons of time That is why it is called fossil fuel.

For generations, the availability of such fuels has been governed by the economics of the refining pro cess. This, in turn, depends upon the availability of petroleum crudes from which the major petroleum companies have been able to produce good quality fuels for use in the diesel engine.

Some years ago, pump fuel and bulk fuel were of consistently high quality, but this has now become more variable — a factor controlled by the availability of world-wide supplies of crude. Because of this the fuel companies have less ability to provide their customers with consistently good fuel of a guaranteed specification and thus the end user, the operator, can suffer. Road transport operators are traditionally among the most hard pressed to maintain the economics of their operation in a period of trade recession and Chalbar suggests that they would be advised to look closely at all the basic factors involved in effective diesel engine performance.

These factors — some obvious, some not so obvious are as follows: a) The basic design and characteristics of the engine in relation to its required performance.

b) The conditions, such as ambient temperature and

The modern tendency in e gine design is to extract high power but without increasir the engine size usually by turb charging. Design fines: especially in the area of fu injection has meant that adjui ment and maintenance ha, become more and ma significant with the more cor plex and sophisticated dies engine. Thus to obtain the be performance from the engin regular maintenance is essent with particular attention to jection pumps and injectors.

Combustion in the comprE sion ignition engine depen upon a well balanced injecti, of a finely atomised fuel togei er with exactly the right quant of air to ensure optimum co, bustion. Induction of air controlled volumetrically ai therefore atmospheric tempe ture, pressure and humidity v ect the actual amount of /gen available for combus-i.

Drivers obviously have a very nificant influence on the permance of a vehicle particuy in the area of smoke emisn where high acceleration :hniques will inject partially imised fuel into the cylinder cause black smoke consist! of carbon particles and unrnt hydrocarbons.

Attempts to govern the enle performance while limiting ) speeds can aggravate the cation by limiting the availle torque from the engine.

jel quality

It is 611 unfortunate fact that a quality of available middlestillate fuels is variable. Alough there has been a very gnificant increase in price ice the Middle East oil crisis is has been accompanied by a icrease in quality. This is par:ularly so in relation to the ,ntent of asphaltenes, waxes id sulphur.

This affects the combustion Jalities of the "fuel with a meral deterioration in pertorance at a time when rising ists and more critical engine asign require just the reverse. It is necessary therefore in any instances to consider the Jality of the fuel as a very gnificant factor in engine perrmance.

It is in this context that the 30 of a fuel control additive )comes significant. The addye itself consists of products hich have both a chemical and lysical effect on the fuel used the engine. There are many tch chemicals available but the ast additives, known as "fuel mtrollers," do not contain free ietals.

The chemicals act on the fuel 'land stabilise it preventing its ossible change between the me it is placed in the tank and s injection into the cylinders. bviously they must be non)xic and non-hazardous and lust be guaranteed not to dalage the engine or affect its forking other than to improve combustion quality of the Jel, Chalbar claims that a number f advantages can be realised by he selection of the right adlitive system!

I An improvement in maintelance cycles, keeping injecors clean and free from deposited hard carbon.

I Stability of the fuel in torage and an improvement in he fuel flow properties.

I Elimination of unscheduled It is an unfortunate fact that, while the use of additives in lubricating oils has been ac

cepted for many years, an additive control system for dery tends to be regarded as "snake oilto be avoided at all cost.

Obviously, an effective additive system must be easy to use and based on sound technology.

This has been proved in the past in the field of lubrication where high-duty products are used in critically operating engines. Their performance is only made possible by the use of an additive package which is an integral part of the product.

As far as Chalbar is concerned the additive is designed for diesel fuel control and it is in this context that it is used to the best advantage. Very small doses placed in petrol can have a beneficial effect acting as an upper cylinder lubricant which is not recommended as there are specific additives available for petrol engines.

Generally speaking, the petroleum companies add everything that is necessary to the petrol before it is actually sold, unlike the situation with diesel fuel which is normally sold on a heavily rebated basis.

Various dosage rates are recommended depending on the state of the engine. Usually a purge treatment is placed in the vehicle tank and this one tank full of treated fuel brings the engine back to the original condition. Subsequently a much smaller dosage (eg 0.5 per cent or one gallon to every 200 gallons of fuel) is added to the bulk storage tank. With the Econosol additive from Chalbar, for example, there is a strong residual effect on the engine.

Although regular treatment of the bulk fuel is recommended, should a driver have to collect a few tanks full ''en route'' there is little falling off in effect until he is able to restock with treated fuel.

The cost of the fuel control additive is slightly in excess of three per cent of the cost of the fuel — in other words, for every El spent on derv, the additive will cost approximatly 3p.

The right additive system can be useful for cutting down on exhaust pollutants both visible and invisible.

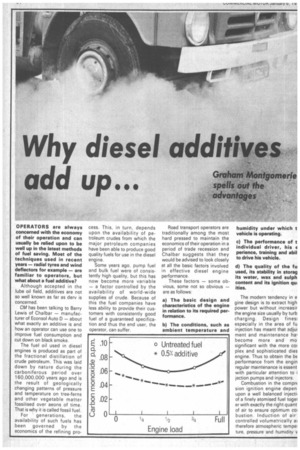

The two graphs show the effect of an additive at a concentration of 0.5 per cent on the visible smoke measured in Hartridge units and on carbon monoxide emission measured in parts per million.

So if you're anxious to squeeze the last useful drop from your fuel, then an additive might be worth considering as it should also give a useful bonus in terms of smoke reduction.