HINTS ON MAINTENANCE.

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

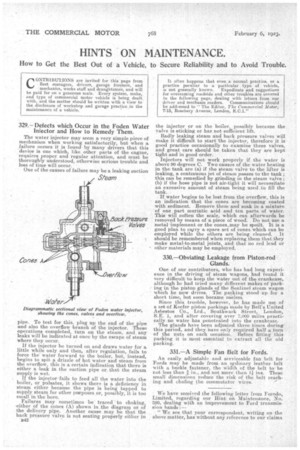

329.—Defects which Occur in the Foden Water Injector, and How to Remedy Them.

The water injector may seem a very simple piece of mechanism when working satisfactorily, but when a failure occurs it is found by many drivers that this device is one which, like other parts of the engine, requires proper and regular attention, and must be thoroughly understood, otherwise serious trouble and loss of time will occur.

One of the causes of failure may be a leaking suction pipe._ To test for this, plug up the end of the pipe and also the overflow branch of the injector. These operations completed, turn on the steam, and any leaks will be indicated at once by the escape of steam where they occur.

If the injector be turned on and draws water for a little while only and then, after regulation, fails to force the water forward to the boiler, but, instead, begins to spit a drizzle of hot water and steam from the overflow, this is a certain indication that there is either a •leak in the suction pipe or, that the steam supply is wet.

If the injector fails to feed all the water into the boiler, or pulsates, it shows there is a deficiency in steam either because the pipe is being tapped to supply steam for other purposes or, possibly, it is too small in 'the bore.

Failures may sometimes be traced to choking, either of the cones (A) shown in the diagram or of the delivery pipe. Another cause may be that the back pressure valve is not seating properly either in

B42

the injector or on the boiler, possibly because the valve is sticking or has not sufficient' lift.

Badly leaking steam and back pressure valves will make it difficult to start the injector, therefore it is good practice occasionally to examine these valves, and great care shouldbe taken that they are kept tight and in good order.

Injectors will not work properly if the water is above 90 degrees C. Two causes of the water heating in the tank are (a) if the steam valve to the lifter is leaking, a continuous jet of steam passes to the tank ; i this can be remedied by grinding n the steam valve ; (b) if the hose pipe is not air-tight it will necessitate an excessive amount of steam being used to fill the tank.

If water begins to be lost from the overflow, this is an indication that the cones are becoming coated with sediment. Remove them and soak in a mixture of one part muriatic acid and ten parts of water. This will soften the scale, which can afterwards be removed by means of a piece of wood. Do not use a metalimplement or the conessmay be spoilt. It is a. good Plan to carry it spare. set of cones which can be employed while the others are being cleaned. It should be remembered when replacing them that.they make metal-to,anetal joints, and that no red lead or other materials may be employed.

330.—Obviating Leakage from Piston-rod Glands.

One of our contributors, who has had long experience in the driving of steam wagons, had found it very difficult to keep the water out of the crankcase, although he had tried many different makes of packing in the piston glands of the Sentinel steam wagon which he DOW drives. The packing stood up for a short time, hut soon became useless.

Since this trouble, however, he has made use of a set of Keefer piston paekings made by Bell's United Asbestos Co., Ltd., Southwark Street, London, S.E. 1, and after covering over 7,000 miles practically no water has penetrated into the crankcase.

The glands have been adjusted three times duringthis period, and they have only required half ,a turn of the nuts on each occasion. Before fitting this packing it is most essential to extract all the old packing.

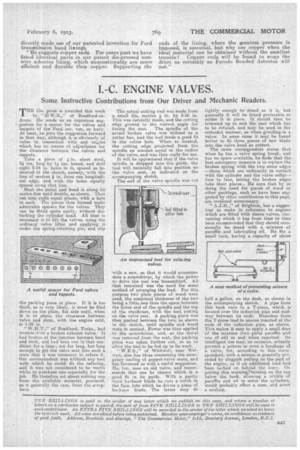

331.—A Simple Fan Belt for Fords.

An easily adjustable and serviceable fan belt for .• Fords may be made from an grdinary leather belt with a buckle fastener, the width of the belt tobe

not less than / in., and not more than ins. These small dimensions reduce the risk of the belt reaching and chafing the commutator wires.

We have received the following letter, from Ferodo, Limited, regarding our Hint on Maintenance, No. no, dealing with an improvement to Ford-transmission bands:—

"We see that. your correspondent, writing on the above matter, has without any .reference to our claims directly made use of our patented invention for Ford trangmission band linings. "He suggests copper ends. For years past we have fitted identical parts in our patent die-pressed nonwire asbestos lining, which unquestionably are more efficient and durable than copper. Supporting the ends of the lining, where the greatest pressure is imposed, is essential, but why use copper when the ideal material can be obtained without the smallest trouble1 Copper ends will be found to score the deuce as certainly as Ferodo Bonded Asbestoi will riot."