CONVERTING VEHICLES TO A LOWER LEVEL.

Page 74

If you've noticed an error in this article please click here to report it so we can fix it.

• A Resume of Recently Published Patent Specifications.

APATENT' (No. 279,696) has been granted to Ernest Usury Glennie and James 'Edward Briant, of Bothwell and Glasgow, for converting existing vehicles of the heavier type, such as buses, to a lower level in the course of reconstructing them. The main part of the idea appears to lie in taking the springs from their beds and turning the axles upside down, then replacing the springs under the axles. Certain new parts, all of well-known type, arc then added, and when completed the arrangement does not appear to us to have any points which can be classed as novel. The granting of a patent for arrangements such as this being somewhat unusual, we give the main claim in its entirety :—

" I. The method of and means whereby motor road vehicles of the heavier class, such as motorbuses, are reconstructed so that the floor level is lower, which e_onsists in turning upside down the spring-seat castings of the rear axle, arranging and securing the rear springs below said castings and the front springs below the front axle instead of over same, bending the side-members of the chassis upwards to clear the rear axle and the members carried by same, bending upwards the cross-member of the chassis in front of and nearest the rear axle to clear the cardan shaft and resetting the rods and members of the brake mechanism and steering gear substantially as set forth."

Cartridges for Grease-guns.

GREASE-GUN lubrication apPears to be increasing in ,populaiity, so that any improvements appertaining to the filling of such guns may be considered interesting to those who have to fill them without using the heavier classes of pump made for the purpose.

The specification of Alfred Bode and Albert Percy

Smedley, No. 279,682, describes a simple form of cartridge in which suitable grease can be packed for handling. According to this specification flaps provided at each end of the paper container are folded over discs at the ends, one of which Is provided with a hole through which the paper bursts when pressure is put on the plunger of the gun.

A Process for Preventing Leaks in Boilers. A PROCESS which should be of interest to all who operate

steam vehicles is described in the patent of Metallisation, Ltd., and Alfred Arthur Arnold, No. 279;584. The invention consists of means whereby metal can be deposited upon any part, such as the seam or rivets of a boiler, to prevent leakage. Reference is made to a co-pending application for a patent, No. 259,289. The main claim in the present patent is as follows:— " Process of rendering joints, seams, rivets and the like fluid-tight, which consists in spraying upon the edges of the joints or seams, rivets or the like, if desired after cleaning same, a suitable metal such as iron, nickel, copper or the like, by means of the metal-spraying process, whereby the joint or the like becomes coated with metal which also penetrates into and fills up any open spaces between the exposed edges of said joint or the like."

Without some explanation readers may not he able to understand what is meant by spraying metal such as iron or copper, hence a slight description of how such metals can be projected in a molten state may be acceptable. A pistolshaped instrument is held in the hand, and a wire of the desired metal is fed through the centre of an acetylene flame, and as it melts it is projected by a blast of compressed air on to the object to he coated. Minute particles of moltenmetal are projected with such force that they adhere to the object, and further spraying causes thole to 'adhere to those particles already on the object, until a layer of sprayed metal can be built up to any desired thickness.

Bel8

A Change-speed Gear Operated by Electra Magnets.

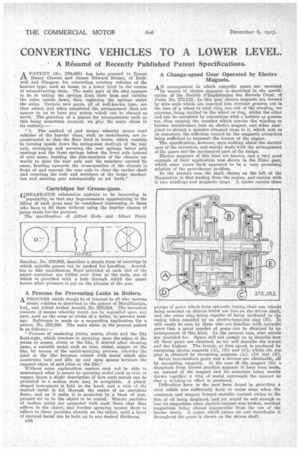

AN arrangement in which epieyelie gears are operated

by means of electro magnets is described in the specification of the Societe .d'Exploitation des Brevets Cotal, of Paris, No. 272,532. In this gear electro magnets are formed by wire coils which are inserted into circular grooves cut in the face of a wheel or steel ring, one cud of the winding we presume, being earthed to the wheel or ring, whilst the winding, end can be energized by connection with a battery or generator, thus causing the member which carries the winding to become transformed into an electro magnet, and when energized to attract a member situated close to it, which acts as an armature, the adhesion caused by the magnetic attraction being sufficient to transmit the torque of the engine.

The specification, however, says nothing about the electric part of the invention, and merely deals with the arrangement of the gears and the mechanical part of the design.

Electro magnets of this kind are known, and a very good example of their application was shown in the Elma gear, which some years back appeared to be a very promising solution of the gear-change problem.

In the present ease the shaft shown on the left of the illustration is that leading from the engine, and carries with it two windings and magnetic rings. A spider carries three

groups of gears which form epicytdic trains, their sun wheels being mounted on Eleeves whieh are free on the driven shaft, and „the outer ring being capable Of being anchored to the casing when required by an electro-magnetic ring (B). It will easily be seen by those who are familiar with epieyclid gears that a great number of gears can be obtained by an arrangement of this kind. In the present case, nine speeds 'are provided for. Space will not permit us to describe how all these gears are obtained, so we will describe the lowest and the highest. The lowest, or first speed, is produced by energizing electro magnets (A), (B) and (C), whilet the top gear is obtained by energizing magnets (A), (0) and .(E).

Seven intermediate gears and a reverse are obtainable, all by energizing magnets. In the case the 'magnet (B) a departure from known practice appears to have been made, as, instead of the magnet and its armature being merely drawn tog-ether, a ring of metal surrounds the magnet so that a winding-en effect is produced.

Difficulties have in the past been found in providing a steel which was sufficiently hard to resist wear when the armature and magnet formed metallic contact owing to the film of oil being displaced, and yet would be soft enough to lose its magnetism when electric contact was broken, residual magnetism being almost inseparable from the use of the harder steels. A pump which raises oil and distributes it throughout the gears is shown on the driven shaft.