BIG-ENDS AND THEIR TROUBLES.

Page 73

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Contributions From Our Driver and Mechanic Readers.

The Vulnerability of Big-ends.

IN Me Commercial' Motor of November 8th we published a letter from "E.F.E." of Bermondsey, dealing with the above subject, and we are glad to see that the points mentioned by him have called forth a large number of letters from mechanics, foremen, etc., all giving facts of real value.

As the big-end is still the most vulnerable part of the modern engine, we propose to devote this page this week entirely to the experiences and suggestions of mechanics on this very important subject, and to follow it up with further letters in our next issue, for although many matters, such as the use of bearings made entirely of white metal, the over-tightening of bolts, tour versus two bolts, the use of split pins, and the pros and eons of letting bearings together or fitting new Ones, are discussed, there are many points that are not mentioned in the letters now appearing.

We would suggest that engine designers would do well closely to follow this discussion.

Bearings Without Shims.

AS regards the oil-ways recommended by " E.F.F.," according to " " .his statement is correct and used by all fitters who have had years of experience; if oil-ways were cut through to the edges of the bearing, in some cases when the pressure gauge is fed from the same pump that feeds the bearing be may find his pressure showing rather low on the gauge, because the oil would be going almost straight through. He also agrees with "E.F.F." as to the taking down of the main bearing' but he points out that while the main bearing that feeds the big-end bearing in question is down, it is advisable to clean out the crankshaft by squirting a pumpful of paraffin through the hole in the main journal of the crankshaft and watch the big-end journal—a few seconds' job, but most important. He has found the hole in the shaft clogged up twice during the last few months, and this not in the same engine.

As regards the fitting of shims, he has always found brass to stand perfectly, but quite agrees that it is liable to hammer out. The material of the shim is not the thing to be tackled : the point is, has the bearing been ttted correctly? Have the brasses of the bearing been taking more pressure than the caps and shim? Have the shims been filed •flat and not left thicker in the centre than the ends?

We will assume the bearing has been fitted correctly. It may be that the bigend bolts have stretched through the use of poor material, or the belts, having been used before, may have had the threads stretched, or may have been injured by continually tightening up while fitting the bearing.

As proof that brass is quite suitable, "1.$.B," says that a short time age a driver had the misfortune to knock out a big-end. He did not telephone, but took off the let. cable of that cylinder and ran home steadily (a thing not LO be recommended, as the big-end may come adrift), a distance of 7 miles. When the sump was dropped the brasses, caps and shims were perfectly tight. Surely this was a severe test?

As to using fibre, " J.S.B." asks: will this stand up to being continually in oil, to extrema temperatures, and remain free from cracking? lie has never used it nor has he ever seen it fitted to an internal-combustion engine with such small bearing-cap surfaces, yet, as a shim, it may stand up on a bearing that does not run in a crankcase.

Lastly, his opinion of a well-designed big-end is the one without shims and with the caps and brasses made to fit. Of course, it has the disadvantage that the bearing cannot be reduced without filing the caps ; but when one can overhaul an engine for a vehicle carrying 6 tons daily and make it last for two or three years, he thinks that it earns a. new set of bearings at the end of that time, especially as the metal must have lost some of its good qualities.

The Fitting of Shims.

oun correspondent, " Ed.," of Pantyffynon, says :— "May I send you some notes on my experience with the fitting of shims to big-end bearings and add my comments with regard to shims hammering out and being found in the sump? I believe that if E.F.F.' has found shims in such a state as he suggests, these shims were never fitted properly, as the brasees must have been loose in the connecting rod and the shims could not have been held tightly between the brasses or bearings. May I now suggest the cause of this, from my own experience as a foreman mechanic? I have found that most mechanics, when fitting new or remetalled bearings, will, in most cases, place the bearing in the keep or connecting rod and then file it off level. This way is wrong, "The correct way is to leave the brasses standing proud above the level of the keep and connecting rod to the extent of about 2-1000th of an inch, and thou, when ;bolted up, the shims will force the bearing home tight in each half of. the connecting rod, and no hammering effect will take place.

"I have fitted all kinds of metal, such as copper, bronze and brass, but have not found them hammer out if held tightly between the brasses.

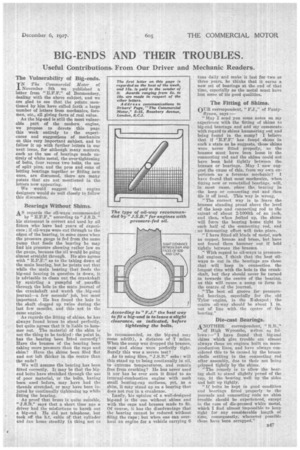

" With regard to oil-ways in pressurefed engines, I think that the best (Always to cut in the hearings are those that will keep in connection the longest time with the hole in the crankshaft, but they should never he turned in towards the centre of the bearing, as this will cause a sump to form in the centre of the journal.

"The best oil groove for pressurefed bearings, especially for the old Tyler engine, is the -shaped; the centre oil-way should be about I in. out of line with the centre of the bearing."

Die-cast Bearings.

ANOTHER correspondent, "

of High Wycombe, writes as fellOWS :—" 1 have found that big-end shims which give trouble are almost always those on engines built on massproduction lines, and have always considered this to be caused by the bronze shells settling in the connecting rod after assembly, due to their not being gripped tightly by the shims.

"The remedy is to allow the bearing hell to stand slightly proud of the cap, fit the bearing well lip the sides and bolt up tightly.

"If bolts be kept in good condition and bearings fitted properly to the journals and connecting rods no shim trouble should be experienced, except in the case of die-pressed white metal, which I find almost impossible to keep tight for any considerable length of time, consequently, whenever possible these have been scrapped."