HINTS ON MAINTENANCE.

Page 72

If you've noticed an error in this article please click here to report it so we can fix it.

Improving the Cooling System of the Peerless. Lubricating the Dennis Steering. Valve Caps for the A.E.C.-Tylor Engine.

Obviating Overheating on the Peerless Engine.

grA NE of the troubles experienced with the Peerlek is k_la tendency for the cooling water to boil under the slightest provocation, particularly when climbing hills under load, but even at times when running on the level. The boiling does not appear to do any harm, but it is a nuisance, as the radiator has to be replenished constantly, and in warm weather these vehicles are often seen running in clouds of steam. Of course, if the overheating be carried to excess, troubles, such as burnt valves, heavy consumption of oil and petrol and extra wear on the bearings, become common, whilst local overheating of parts of the cylinders may cause serious distortion.

By keeping the wire gauze in the water pump clear and the fan in as good working order as possible, some improvement in running is obtained, but not sufficient.

The main cause of the overheating lies in the cooling system, there being a scarcity of water around the cylinder heads, whilst the exit from the cylinders to the radiator is too restricted, being less than 1 in. in ham in some parts, and the water-chamber covers are too flat, causing back pressure on the pump and slowing the circulation of the water.

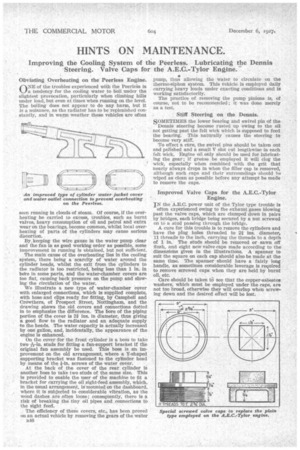

We illustrate a new type of water-chamber cover with enlarged connections, which is supplied complete, with hose and clips ready for fitting, by Campbell and CroWthers, of Prospect Street, Nottingham, and the drawing shows the old covers and connections dotted in to emphasize the difference. The bore of the piping portion of the cover is 2k ins, in diameter, thus giving a good flow to the radiator and an adequate supply to the heads. The water capacity is actually increased by one gallon, and, incidentally, the appearance of the engine is enhanced.

On the cover for the front cylinder is a boss to take two -8F-in. studs for fitting a fan-support bracket if the original fan assembly be used. This boss is an improvement on the old arrangement, where a Y-shaped supporting bracket was fastened to the cylinder head by means of the i-in. screws of the water cover.

At the back of the cover of the rear cylinder IS another boss to take two studs of the same size. This is provided to enable the user of the machine to fit a bracket for carrying the oil sight-feed assembly, which, in the usual arrangement, is mounted on the dashboard, where it Is subjected to considerable vibration, as the wood dashes are often loose; consequently, there is a risk of breaking the tiny oil pipes and connections to the sight feed.

The efficiency of these covers, etc., has been proved on an actual vehicle by removing the gears of the water n46

pump, thus• allowing the water to circulate on the thermo7siphon system. This vehicle is employed daily carrying heavy loads under exacting conditions and is working satisfactorily.

The practice of removing the pump pinions is, of course, not to be recommended ; it was done merely as a test,

Stiff Steering on the Dennis.

SOMETIMES the lower bearing and swivel pin of the

Dennis steering become rusted up owing to the oil not getting past the felt wick which is supposed to feed the bearing. This naturally -causes the steering to become very stiff.

To effect a cure, the swivel pins should be taken out and polished and a small V slot cut lengthwise in each felt wick. Engine oil only should be used for lubricating the gear ; if grease be employed it will clog the wick, especially when combined with the grit that nearly always drops in when the filler cap is removed, although such caps and their surroundings should he wiped as clean as possible before any attempt be made to remove the caps.

Improved Valve Caps for the A.E.C.-TyIor • Engine.

IN the A.E.C. power unit of the Tylor type trouble is often experienced owing to the exhaust gases blowing past the valve caps, which are clamped down in pairs by bridges, each bridge being secured by a nut screwed on to a stud passing through the bridge.

A cure for this trouble is to remove the cylinders and have the plug holes threaded to 2,1 ins. diameter, 11 threads to the inch, carrying tile threads to a depth of 1 in. The studs should be removed or sawn off flush, and eight new valve caps made according to the dimensions given in the illustrations. A spanner to suit the square on each cap should also be made at the same time. The spanner should have a fairly long handle, as sometimes considerable leverage is required to remove screwed caps when they are held by burnt oil, etc.

Care should be taken to see that the copper-asbestos washers, which must be employed under the caps, are not too broad, otherwise they will overlap when screwing down and the desired effect will be lost.