Extracting Ferreous Particles From Oil.

Page 71

If you've noticed an error in this article please click here to report it so we can fix it.

OUTSTANDING amongst the factors which hasten deterioration in the working parts of an internal-combustion engine are the numerous particles of metal which, during the running of the motor, beeome suspended in its lubricating oil. These, of course, are usually detached from the Working parts themselves owing to wear and tear, and are generally of steel, iron, brass or white metal. Those of brass and white metal are comparatively soft and cause, therefore, but little harm to the bearing surfaces with which they come into contact, but those of steel and iron are extremely hard and are thus able easily' to penetrate the oil film on any bearing. Once they have passed through this film of lubricant, which is usually not more than one tenthousandth of an inch in thickness, they assume an abrasive quality, which causes much wear and other damage to the working parts concerned.

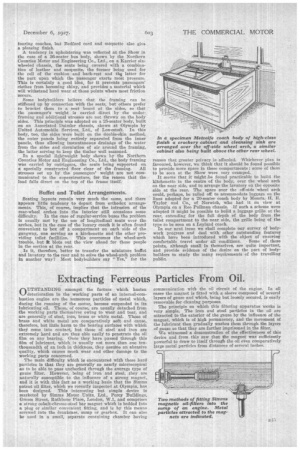

The main difficulty which is encountered with these hard particles is that they are generally so nearly microscopical as to be able to pass unchecked through the average type of gauze filter. However, being of iron and steel, they are naturally susceptible to the influence of a strong magnet, and it is with this fact as a working basis that the Simms patent oil filter, which we recently inspected at Olympia, has been designed. This interesting but simple device is marketed by Simms Motor Units, Ltd., Percy Buildings, Grasse Street, Rathbone Place, London, W.1, and comprises a strong cobalt-chrome-steel bar magnet which is bedded into a plug or similar convenient fitting, and is by this means acrewed into the erankcaee, sump or gearbox. It can also be used in a small, separate containing chamber having

communication with the oil circuit of the engine. In all cases the magnet is fitted with a sleeve composed of several layers of gauee and which, being but loosely secured, is easily removable for cleaning purposes.

The principle on which this filtering apparatus works is very simple. The iron and steel particles in the oil ace attracted to the exterior of the gauze by the influence of the magnet, which is of high permanency, and the movement of the lubricant then gradually washes them through the layers of gauze so that they are further imprisoned in the filter. We witnessed IL demonstration of the effectiveness of this device and from this saw that the magnet was sufficiently powerful to draw to itself through the oil even comparatively large metal particles from distances of several inches.