HINTS ON MAINTENANCE.

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

CONTRIBUTIONS are invited for this page from fleet managers, drivers, garage foremen, and mechanics, works staff and draughtsmen, and will be paid for on a generous scale. Every system, make, and type of conunercial motor vehicle will be dealt with, and the matter should be written with a view to the disclosure of workshop and garage practice in the maintenance of a vehicle—practices

128.—Economizing Oil in Dennis Engines.

All engines employed on the Dennis chassis are, as a rule, very economical in the use of lubricating oil, and if there is any tendency to smoking or extravagance in the use of oil, the cause can be traced in almost every instance to the oil scraper rings which are fitted to the skirts of thepistons. On careful examination, these rings will be found to be Stepped: When this step is worn down or is flush with the remaining portion of the ring it is no longer definitely effective, and should be replaced. „

When making a replacement, the step portion of the new ring should be at the bottom. The alteration may not be instantly effective, but after a short period of running the new rings will bed into position and normal -conditions will be restored: The.rings should be examined when the cylinders are lifted to.clean the pistons or during the overhaul, and replaced if necessary. They are not costly, and will amply repay attention in the saving of lubricant.

129.—Timing-case Gland on Tylor Engine.

A trouble which sometimes occurs with the ring nut holding the oil-retaining gland in the timing ca-se of the: Tylor engine is stripping of the thread in the timing case, owing to the fact that the ring can only be done up finger-tight, otherwise the white-metal oil: retaining ring may seize and run. Consequently, when the main bearings become a trifle slack, there is a hammering action on the ring, and the latter, having no locking device other than al, in. grub strew, soon frets awaY the thread in the case. Prevention being better than cure, the following procedure has been found to stop the trouble. Out out three or four rings from in. sheet iron, and of a suitable size to fit over the threads of the ring nut and yet to butt up against the collar These rings act asi distance pieces, and sufficient should be inserted between the nut and the face of the timing ease to allow the nut to be screwed home until it is tight against the casing and just piriching the oil-retaining gland.

which, whilst they may be quite normal, are peculiar to the particular vehicle and may not be generally known to those responsible for its running. Expedients and suggestions for overcoming roadside and other troubles are covered in the rollowing page, headed "Roadside and Garage." Communications should be addressed to "The Editor, The Commercial Motor, 7-15 Rosebery Avenue, London, RC. 1."

When adjustment is again needed it is only necessary to remove one of the rings and again to tighten the gland nut.

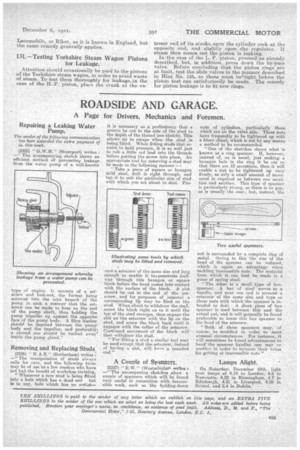

130.—Improving Peerless Water Pump.

The water-cooling system on Peerless chassis may be drained by means of a screwed plug in the base of the water-pump body, and through another screwed

plug in the radiator pipe, but it is impossible completely to drain the pump gear chamber by means of these two exits.

This is because the inlet to the chamber is about 2 ins, above the bottom, as is shown in the diagram, so that, when the water drains out of the pump over the lip of the inlet, a certain quantity is left in the base of the pump gear chamber. This naturally causes trouble in frosty weather, as the gear wheels freeze up, generally resulting in the shearing of the shaft coupling pin, or causing other damage which cannot be easily repaired, and which may place the vehicle in dock for a day or more. To remedy this defect it is only necessary to drill a hole of about in diameter through the base.of the pump-gear chamberinto the intake from the radiator. This enables the water to drain away. From a theoretical point of view the provision of this hole is bad, as it reduces the output of the pump, but its effect is hardly noticeable in .practice; in fact, during a long run in the hottest weatheobservers have been unable to notice any reduction in the efficiency of the cooling-water system. A similar defect will be found in several other water-circulating pumps, as, for instance, in the Locomobile, or Riker, as it is known in England, but the same remedy generally applies.

131.—Testing Yorkshire Steam Wagon Pistons for Leakage.

Attention should occasionally be paid to the pistons of the Yorkshire steam wagon, in order to avoid waste of steam. To test them thoroughly for leakage, in the case of the H.-P. piston, place the crank at the ex

treme end. of its stroke, open the cylinder cock at the opposite end, and _slightly open the regulator. If steam then comes out the piston is leaking. In the ease of the L.-P. piston, proceed. as already described, but, in addition, press down the by-pass valve. Before concluding that the piston rings are at fault, test the slide valves in the manner described in Hint No. 125, as these must bettight before the piston test can satisfactorily be made. The remedy for piston leakage is to fit new rings.