Solid choice for FH discs

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

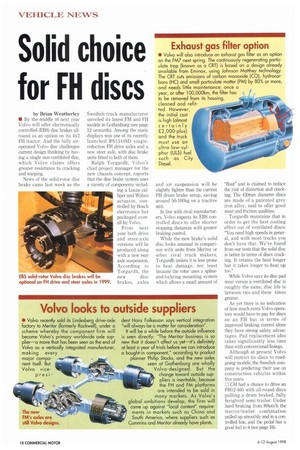

by Brian Weatherley • By the middle of next year Volvo will offer electronically controlled (EBS) disc brakes allround as an option on its 4x2 Fl-1 tractor. And the fully airoperated Volvo disc challenges current design thinking by having a single non-ventilated disc, which Volvo claims offers greater resistance to cracking and warping.

News of the solid-rotor disc brake came last week as the Swedish truck manufacturer unveiled its latest FM and PH models in Gothenburg (see page 12 onwards). Among the static displays was one of its recently launched RS1344SD singlereduction FH drive axles and a new steer axle, with disc brake units fitted to both of them.

Ralph Torgardh, Volvo's chief project manager for the new chassis concept, reports that the disc brake system uses a variety of components including a Lucas calliper and Wabco actuator, controlled by Bosch electronics but packaged overall by Volvo.

From next year both drive and steer-axle versions will be produced along with a new rear axle suspension. According to Torgardh, the new disc brakes, axles and air suspension will be slightly lighter than the current FH drum brake setup, saving around 50-100kg on a tractive unit.

In line with rival manufacturers, Volvo expects its EBS controlled discs to offer shorter stopping distances with greater braking control.

While the new brake's solid disc looks unusual in comparison with units from Mentor or other rival truck makers, Torgardh insists it is less prone to heat damage, not least because the rotor uses a splineand-lockring mounting system which allows a small amount of

"float" and is claimed to reduce the risk of distortion and cracking. The 430rtun diameter discs are made of a patented grey iron alloy, said to offer good wear and friction qualities.

Torgardh maintains that in order to get the best cooling effect out of ventilated discs: "You need high speeds in general, and with most trucks you don't have that. We've found from our tests that the solid disc is better in terms of discs cracking. It retains the heat longer but it takes longer to heat up too."

While Volvo says its disc pad wear versus a ventilated disc is roughly the same, disc life is between two and three times greater.

As yet there is no indication of how much extra Volvo operators would have to pay for discs on an FH but in terms of improved braking control alone they have strong safety advantages. Pad replacement also takes'significantly less time than with conventional linings.

Although at present Volvo will restrict its discs to roadgoing models, the Swedish company is predicting their use on construction vehicles within five years.

CM had a chance to drive an FI-112-460 with all-round discs pulling a drum braked, fully freighted semi-trailer. Under hard braking from 80kin/h the tractor/trailer combination pulled up smoothly and in a controlled line, and the pedal has a good feel to it (see page 16).

Exhaust gas filter option

• Volvo will also introduce an exhaust gas filter as an option on the FM7 next spring. The continuously regenerating particulate trap (known as a CRT) is based on a design already available from Eminox, using Johnson Matthey technology. The CRT cuts emissions of carbon monoxide (CO), hydrocarbons (NC) and small particulate matter (PM) by 80% or more, and needs little maintenance: once a year, or after 100,000km, the filter has to be removed from its housing, cleaned and refitted. However,

the initial cost is high (almost certainly £2,000-plus) and the truck must use an ultra-low-sulphur (US) fuel such as City Diesel.