Contributions from Drivers and Mechanics.

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

Ten Shillings Weekly for the Best Communication Received, and One Penny a Line of ten words for anything else published.

Drivers of commercial motors, and niechanics and foremen of garages or shops, who are engagei in any branch of the industry, are invited to contribute short, personal experiences, °Pinions, or suggestions, on subjects which are likely to prove of interest to our readers. We shall be glad to hear of anything interesting that has come under any driver's or mechanic's notice, either in the shops or On the road. Long and successful runs ; services with no " lost journeys" ; workshop tips and smart repairs : all are suitable. subjects. Send a Post-rcerel, Or a letter, or a sketch to us—no matter how short, or how written, or how worded. We will " knock it into shape" before Pnblicalion. When writing, it is as well to mention your employer's name as a guarantee of bona fides (not for publication), and to state whether you w.sh your own name, or initials only, to be publ is h e d . Payment will be made immediately. after publication. Address your letters to The Editor, " THE COMMERCIAL Mo-rots," 7-15, kosebery Avenue, London, E.C.

Mild-steel Piston Rings.

[4[51 The achievement of a repair job, which displays very considerable mechanical skill and initiative, has prompted the communication of the following account to us by M. V. CAMBRIDGE (Portsmouth) :—" I recently had occasion to effect a repair to a small compound steam engine, which was used for auxiliary work, and the method, which I was able successfully to adopt, has suggested to me that a similar dilemma, if it occurred on a steam wagon or tractor, might with great advantage be solved in like manner.

" The engine in question was of the small vertical compound type, and its temporary incapacity was due, I found, to the breakage of the gun-metal piston rings in the L.P. cylinder. The only reasonable remedy, of course, was to fit new rings, but this, in the absence of spares, is never a job which can he done in a moment. It was, in this case, impossible to secure new rings within a reasonable time, and, of course, a pattern and new C.I. or G.M. castings would have involved two or three days' delay at the least. "1, at first, seemed to be up against a brick wall, but, after thinking over every possible means of making a sound repair, even if it were only a temporary one, I resolved to try and make .a pair of mild-steel rings. As luck would have it, I could not lay my hands on a piece of square bar, and I had to he content with a length of i-inch round stuff. I cut off a piece equal in length to rather more than the circumference of the piston, and, after a deal of trouble, I eventually managed to hammer out a ring with a flat section of sufficient size to cut into two rings. I did not dare to attempt to weld the ends, as I feared I should spoil the circle, although this would have considerably facilitated the subsequent machining. In the absence of the proper appliances for bending or forming the ring, it took me a long time to get the ring true enough to be serviceable.

" I clamped the rough-forged ring up to the lathe face plate, and turned it up, by degrees, to a inch larger than the piston bore. Owing to the split in the ring, I had to take very small cuts, and the process was rather a tedious one, but I eventually managed to bore and face it, and then nearly to divide the two rings. I finished the division with a hacksaw, for fear that the forging would jump out of the dogs. I fitted the butted ends with a file, so that the rings would very nearly close when placed in position. After carefully fitting the rings in the grooves, I closed the cylinder up again, and I am pleased to say my mild-steel rings have run quite satisfactorily ever since.

" With the help of a good smith, it is quite possible that a steam road vehicle, which would otherwise be kept out of service for some days with broken rings and no spares, might be quickly got to work again in the manner I have endeavoured to describe."

Hints .for White-metalling.

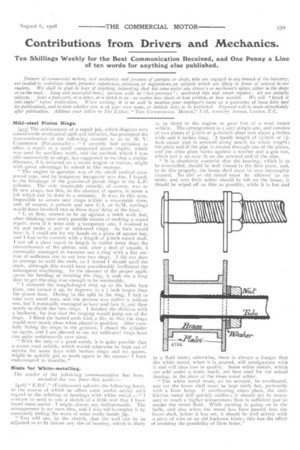

The sender of the following communication has been awarded the loc. prise this week:— kid] " B.1LC." (Eastbourne) submits the following letter, in the course of which he offers some useful advice with regard to the relining of bearings with white metal :—" venture to send to you a sketch of a little tool that I have found most useful—I might almost say, indispensable. The arrangement is my own idea, and I was led to employ it by constantly feeling the want of some really handy jig. " You will see, by the sketch, that the tool can be so adjusted as to fit almost any size of bearing, which is likely

to be fitted to the engine or gear box of a road motor vehicle. The arrangement is a very simple one, and consists of two pieces of I-inch or 5-M-inch sheet iron about 4 inches wide and 6 inches long. A handy length of ti-inch or t.4inch steam pipe is screwed along nearly its whole length ;. the plain end of the pipe is riveted through one of the plates, and the other plate backs against a washer and a gas nut, which nut is an easy fit on the screwed end of the pipe.

" it is absolutely essential that the bearing, which is to be remetalled, should be well tinned in the first place, and, to do this properly, the brass shell must be very thoroughly cleaned. No dirt or old metal must be allowed to remain, and very little solder should be left on the brass; it should be wiped off as thin as possible, while it is hot and in a fluid state; otherwise, there is always -a danger that the white metal, when it is poured, will amalgamate with it and will thus lose in quality. Some white metals, which are sold under a trade mark, are best used for the actual tinning, in the place of the more usual solder. " The white metal must, on no account, be overheated, and yet the brass shell must be kept fairly hot, preferably with a blow lamp. If everheating takes place, the antifriction metal will quickly oxidise; it should not be necessary to reach a higher temperature than is sufficient just to render the metal fluid. While melting is going on in the ladle, and also when the metal has been poured into the brass shell, before it hiss set, it should be well stirred with pioce of wire or an old hacksaw blade; this has the effect of avoiding the possibility of blow holes."