"THE COMMERCIAL MO] )NE-TON VAN CHASSIS.

Page 16

Page 17

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

IN the design of a one-ton van, intended to combat the foreign competition which is undoubtedly pressing the British manufacturer at the present moment, so many debatable points arise that it is difficult to decide how far one should go towards producing the " cheapest !possible " model—one which is cheap only from a matter of first cost—and whether it would not be better to follow the lines which have characterized British manufactures hitherto and to produce a machine which will not be the " cheapest possible," but will give thorough satisfaction and be economical. in use.

A van which is cheap to buy but is not economical in-use does not recommend itself to a business man. It must be remembered that it,is not only the cost of the van which has to be considered ; it is the cost of carrying the-goods which matters. As an example of what we mean, we would point to a certain American outfit which does duty for a pleasure car and with certain modifications, as a one-ton van. This chassis has an engine which is precisely similar in ita bore and stroke to that of a well-known British van built to carry two and a half tons, which load it carries well with no greater consumption of petrol or lubricating oil than its foreign competitor employs in carrying one ton.

The matter of depreciation is one which cannot be overlooked. In the earlier days of American history it was thought that machinery could be made on the principle of the famous one-horse chaise, which was designed so skilfully that all parts wore. out at exactly the same time.

Attempts were made in America to construct lathes, locomotives and other machinery on these lines, with the idea that they should last just so long and then he scrapped. This line of policy, however, has not turned out to be a success and, gradually, the need for giving durability to the article has been studied and means have been provided for renewal of wearing parts, until, to-day, we see the American lathe and locomotive every bit as well made, as expensive, and as long-lasting as those of British manufacture-. In other words, the Americans have abandoned the cheap, and nasty method, and have followed on the British lines of making a machine as well as it can be made, with as full a regard for durability and long life as has assisted in the past to establish world-wide reputation. for all British productions.

This, we predict, is what will eventually happen with the motorvan. The idea of making a van which will run well for a few years and can then he scrapped is nonsense, as it is an undoubted fact, that, long before the scrapping time arrives, the thing begins to give trouble here and there. When patterns were altering quickly

and improvements were being introduced rapidly, there was some reason for the scrapping idea, but, with our present-day knowledge, there is no reason why a van should not be quite serviceable in ten years' time, or even after a longer period of service, provided all wearing parts have been cheaply renewable and that the design is such that a fair amount of neglect and rough handling do not injure it. The lasting properties of a van cannot be disregarded when the cost of carrying goods is considered, as the matter of depreciation is so materially affected by it.

The design of a one ton van to meet foreign competition is no easy task. The main selling feature of the foreign production is its low first cost, and, although English buyers do not, as a rule, make this the leading factor when deciding on a particular make, it undoubtedly has a great influence in Colonial and other markets. Home demand alone will not warrant a sufficiently large output to enable the subject to be properly tackled, and it is, therefore, necessary that a model should be designed which will be equally useful for home and abroad—in other words, for a world's trade.

It is impossible that, in connection with any new production, there can instantly any organized a system of servicewhich will compare, in completeness or extent, with that which has, in the course of years, been built up for the older makes of vehicles. Good service is a great lever in selling a vehicle, especially in countries-where replacements will take a. long time to get from the makers. As such a service cannot be instantly installed, the next best thing is to be sure that such parts as are likely to be damaged by accident and are likely to suffer by wear are few in number and are not too costly, so that each purchaser can afford to have a stock of the most vital parts if he should be out of touch with the makers of the vehicle.

The next alternative is to see that such parts ate so designed that, if absolutely necessary, they could be made locally. It is also necessary to see that such parts shall be as inexpensive as possible, compatible with efficiency. Another point to observe in the design is that all repairs can, so far as possible, be done by a person of limited skill. Low first cost may; irk some cases, be a very important matter where only a small amount of mileage is required of a vehicle, but, where an ordinary mileage may be expected, it is not the cost of the vehicle alone which should he considered ; it is the cost of carrying the goods that matters. The points which govern this are low consumption of petrol and economy of lubricating oil. Petrol may be saved in two ways—namely, by efficiency in engine and by efficiency in transmission. In designing the vehicle detailed in the following specification, we have taken all the foregoing points into consideration, and if some of the-methods embodied seem like returning to prude and superseded devices, it must not be thought that, in consequence, the vehicle must be somewhat out of date.. We have chosen each detail with regard to the foregoing circumstances, and have selected what we consider the most suitable.

In order to comply with Colonial conditions, high clearance in both axles is essential, and the width of the wheel track should either be such that it will fit the tracks made by other vehicles in new countries as a standard, or, if that is not possible, the design should be such that the width can easily be altered to suit the requirements of different markets.

Features of the Four-cylinder Engine.

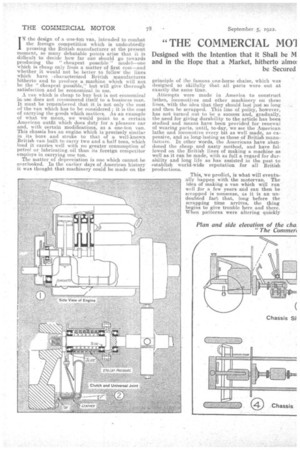

In the design of an engine suitable for the particular purpose we have in' mind, although every consideration should be given to simplicity and cheapness of production, there are other things which should have equal attention. Such an engine should be, efficient, and all wearing parts should be easily renewable and be of such a kind that they can be fitted by a person Of little skill. For this reason an engine has been chosen which has two ball bearings to both crankshaft and camshaft. Fig. 1 shows the engine which, it will *he seen, has cylinders cast en bloc and integral with the crankcase. The head of the engine is a separate part, of cast-iron, and the lower part contains troughs and strainers of aluminium. A chain is suggested as the simplest and cheapest drive for camshaft and magneto. A rocking platform for the magneto will permit of adjustment of its driving chain. An exhaust and inlet pipe formed in one piece is suggested, as it provides a means of warming the inlet and simplifies construction.

The ball bearings of the camshaft and crankshaft are of the double-purpose type, which form in themselves thrust and journal bearings, and so simplify construction and reduce cost. At the rear end of the crank a washer is provided, which prevents oil leakage. A thin washer is allowed to hear against the non-revolving-member of the bearing, which will stop any excessive amount of oil from passing the bearing. A second washer is also .provided which will return any slight leakage of oil to the main sump. The gudgeon pins are loose and allowed to work in both connecting rod end and piston. They are secured in place by chaplets. Gunmetal lined with a thin layer of best-quality white metal is suggested for the big-end bearings, as this is a. part where any economy carried to the extent of reducing efficiency would be a fatal error. Laminated shims soldered together in a pack are suggested for the big-end bearing. These are more satisfactory than a number of loose pieces, and are easily managed when -being fitted. Pistons of the split-sleeve type and made of cast-iron, are recommended as the most satisfactory and the most ecOnomical as regards oil consumption. With these pistons a plentiful amount of oil may he allowed for the big-ends, as this type of piston will not allow any /excessive amount of oil to pass it. Mushroom tappets are recommended. Lubrication by means of troughs is suggested, as it can be thoroughly relied upon, and it does not necessitate the very dangerous practice of drilling the crank, which in so many instances is the cause of fracture.

The Need for Water All Round Each Cylinder.

The question of whether there should be water between the cylinders is one in which there may be differences of opinion. It is true that engines are made which give satisfaction in which there is no water between the cylinders, but the practice cannot be said to be a good one, and if the model under consideration is for all climates and for rough work, it should not be followed. The engine shown in Fig. 1 provides for water all round each cylinder. 034

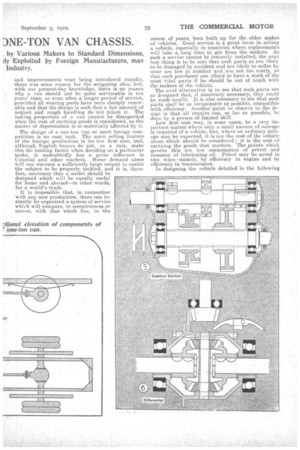

The idea of a two-ball bearing crank and caliashaft is one about which some may have their double. The success of such a design, however, depends largely on the proportions of the crankshaft and camshaft. It is most important that the webs of the crank should be of such a proportion in relation to the journals that no unduly weak spot exists where any flexion is excessive. Well-designed radii should be provided at the ends of the journals. If these points be attended to andthe material is right, there should be no trouble. As to the camshaft the same thing applies. It must, of course, be larger in diameter than one with three bearings. The advantages of the plan is its extreme simplicity in machining, its efficiency, and the ease with which it can be demounted and new bearings fitted. The dutch is a mbst important part in the design, as such a van is likely to be handled by persons of very little skill, if a world's trade is to be catered for. It is now a well-known fact that the proportions of the transmission, which will answer perfectly well when working in conjunction with an epicyclic gear (in which a band is used instead of a clutch), will prove a complete failure when connected up to an engine through an ordinary cone clutch. This fact has been so amply proved that it shows the importance of greater attention being paid to the construction of a clutch if a light and inexpensive transmission system is to be relied upon.. The form of clutch shown in Fig. 2 has been selected on account of its extreme softness in action and the little care and attention which it requires. It will be seen that a steel pressing is bolted -to the -flywheel and that an oil-tight joint is necessary at its junction. This forms the outer member and also the retainer of oil. The inner member is also a pressing, and has a second disc fitted by its side to collect any oil that may gravitate down its outer face. when not revolving. The outer member may be filled with oil in sufficient quantity to form a complete bath, which cannot escape, owing to the inturned edge of the outer member and the conical disc.

The Advantages of the Oil-immersed Clutch.

It may be said by those not familiar with this form of clutch that it will not grip, owing to the great amount of oil present. This, however, is not the case, provided the angle of the cone is correct. An angle of 7 degrees (with the axis of the shaft) has been found to work quite satisfactorily with an oil bath and to require ,no attention and, at the same time, to answer equally well in the hands of the inexperienced, as, no matter how carelessly the dutch is operated, the oil necessarily takes a few moments before the clutch takes up. It will be seen that a simple cone is provided for attaching the flywheel to the crank. The large diameter necessary for a ball bearing affords a very efficient means of attaching a flywheel in this manner. A stud forms a means of holding the wheel on to the, cone and, at the same time, forms a spigot for the sliding member. Ball bearings are used here and are allowed to slide in the. spigot where indicated in Fig. 2. It will be seen that one of these bearings is of the double-purpose type, while the other is of

erdinary type. A double-purpose bearing of thee same size constitutes the clutch-withdrawal bearing.

We now come to the universal joint between the engine and the gearbox. Before describing this, it may he as well to explain why a self-contained unit for engine and gearbox has not been adopted. In our opinion it is one thing to design and make a van, and quite another thing to have to keep it running under ordinary conditions, to say nothing of Colonial conditions. The man who has to keep things going usually favours separate units, and, in the circumstances, we are prepared to agree with him. It will be noticed that only one universal joint is shown between the engine and the gearbox. It must not, however, be thought that one ordinary joint is intended. 'The joint shown is of a special

type' details of which we are not at liberty for the present to publish. This joint will allow errors of alignment as well as of the direction of the shafts. In some recent designs a single joint is used in this position. It is evident that the alignment of such shafts cannot be relied upon, and, as an ordinary single joint will only permit errors of direction of the shafts, the employment of a single joint of ordinary construction is obviously unfair to the joint and to all the surrounding parts. The gearbox will be seen to be of the type where there is no direct gear on top. Two shafts are placed one above the other, and, even in top gear, there is a reduction of 20 to 25. Fig. S shows the arrangement and ratios of gears and numbers of teeth and pitch. The shafts have no splines. In the case of the upper shaft th re are -ordinary Woodruff keys, which ensure rkation, and distance collars which determine the positions of the wheels. The whole series of wheels and ball bearings is nutted up as et whole. The lower shaft is hardened and provided vditli• two key-ways. The wheels, which slide, are fitt d with keys with enlarged ends, as shown in the d agram. This ensures the keys moving with the wh la and prevents them from getting adrift. The obeei of this arrangement is that the mating surfaces of tic wheel' and shaft can be ground so as to ensure oncens tricity. The supports of the gearbox ire so. arranged that it can be lowered without disnjantlmg any other parts excepting the universal jo nts. A central gate is provided.

Flexible " rag " joints connect the drive to the light tubular cardan shaft which transini4 power to the rear bevel pinion.

Why a Bevel-driven Rear Axle is Fav ured.

The suggested design for the rear axle is the straight bevel type. In spite of results which may have been obtained in laboratory tests witi worm drive, results on the road, under actual loaqi carrying in commercial work, have convinced th writer that appreciably greater economy may be epspected from gearbox reduction and final bevel gear drive than from worm. drive.. In the matter of a hack axle it is not easy to effect much in the way of eco omy in design without reducing its usefulness. Fig. 6 shows an ordinary differential with a pin of .plain steel passing right through and carrying the pmio s. This pin is secured by two of the bolts which hold the ease together, cutting slightly into it. The driving shafts are strong enough to permit the use of twin tyres.

With regard to steering gear, it is very doubtful, when all things are considered, whether any arrangement of internal wheel and pinions can be produced more economically than an ordinary small worm and wheel of the same strength. Absolutely irreversible steering worms require to be very much heavier than those in which there is a slight give back when the road' wheel is moved. The secret of success in the ridiculously light and flimsy American type of steering lies in the fact that it is not irreversible.

Fig. 7 shows a design of front axle which has been found to stand up to the roughest work. It may have a somewhat crude appearance, but it has the following advantage over a stamped axle for Colonial work. In rough country, the front axle is the part most likely to get damaged. Colonials prefer a design where, should any part get damaged, they can improvise another at the nearest blacksmith's. With this in view, the axle shown in Fig. 9 has been designed. It will be seen that the central portion is merely two plain lengths of steel, bent to shape and welded, with distance pieces between them

below the spring soles. The spring soles are formed by the springs lying on the flat metal. If the plates which hold the springs are placed under the axle as shown, there is no fear of any part coming adrift. The stub ends shown are formed separately from the steering head, so that, in case of damage, a new one could be made in any place where there is-a lathe. The steering arm, which is of standard pattern in its body, has a taper where it fits into the head.

With a view to reducing petrol consumption by employing the most efficient form of transmission it is suggested that a bevel gear and double reduction in the form shown (in the gearbox) be adopted. Our designer is confident that this system of transmission is more economical than by one in which the worm is employed, and he claims to have ample proof to back his opinion. By the arrangement shown, a bevel pinion of ample proportions can be used which is in every way more economical than worm gearing. Reduction in the gearbox itself renders this possible

TheAdvantages of Rolled Channel Steel.

Rolled channel steel is suggested for the frame members, in plate of the ordinary pressing, on the grounds of first cost and ease of replacement in case of accident away from supplies of spares. Our designer knows that many will differ from him in this point, but he is not speaking without his book, and gan fully justify his contention on this point. The gusset in the corner, of rolled section, enables the member to withstand greater racking and twisting than the pressed section, 'where there is an even thickness all round. All that is needed is two straight rolled members bolted to crossmembers by means of gusset plates. No rivets should be used in the construction of the frame. Dumb-irons are not needed, as they are only an attempt to follow pleasure car practice and are a weak spot. They are expensive items and are not necessary, as a simple bracket under the frame is all that is needed. This can be alike for front and rear ends of front springs,

The common leaf springs are hard to beat for ordinary use, but some provision should be made so that supplementary springs could be added for Colonial use without interfering with standard patterns.

A radiator with removable top and bottom would, no doubt, be appreciated by users on account of its eate of repair, but its higher cost isagainst it in the design we have under consideration. Thermo-siphon circulation is the simplest and therefore is recoms mended. A radiator guard should be fitted.

The load should be disposed well over the back axle, so as to relieve the front axle, wheels, tyres and all parts connected with the front of the vehicle from weight, so far as is possible. By attention to this point, all the components of the front part can he considerably reduced in first cost and in replacement cost.