ROADTEST IVECO FORD 190.36

Page 54

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

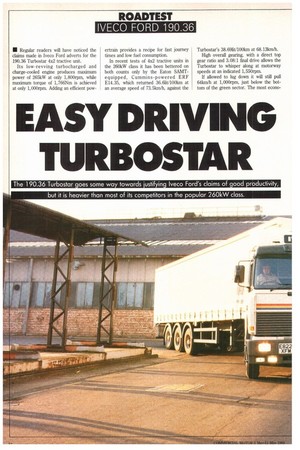

• Regular readers will have noticed the claims made in Iveco Ford adverts for the 19(136 Turbostar 4x2 tractive unit.

Its low-revving turbocharged and charge-cooled engine produces maximum power of 265kW at only 1,800rpm, while maximum torque of 1,766Nm is achieved at only 1,000rpm. Adding an efficient pow ertrain provides a recipe for fast journey times and low fuel consumption.

In recent tests of 4x2 tractive units in the 260kW class it has been bettered on both counts only by the Eaton SAMTequipped, Cummins-powered ERF E14.35, which returned 36.6R/1001cm at an average speed of 73.5km/h, against the Turbostar's 38.691it/100km at 68.13km/h.

High overall gearing, with a direct top gear ratio and 3.08:1 final drive allows the Turbostar to whisper along at motorway speeds at an indicated 1,550rpm.

If allowed to lug down it will still pull 641un/h at 1,000rpm, just below the bottom of the green sector. The most econo mica! speed is indicated by a wedge on the rev counter covering 1,100 to 1,400rpm, which is ideal for dual carriageway running. Where it became clear that a downward gearchange would be needed we chose to make it early, but for the most part keeping within the green sector.

This may not be the way to achieve the ultimate economy, but it does help to maintain good journey times without a significant increase in fuel consumption.

Only while climbing the steepest hills, over the most difficult A68 section of the route, did we boost the revs to gain maximum power.

• TRANSMISSION

The standard transmission specification includes a 16-speed ZF synchromesh gearbox which incorporates a split on each of its eight full gears. A Fuller 14613 13speed constant-mesh box is also available.

Earlier this year we had cause to criticise the ZF's double-H shift, and Iveco Ford was also less than happy with it. It was subsequently examined by ZF and Magirus engineers from lveco's heavy truck plant at Ulm, West Germany, who declared everything to be normal.

The problem arises from the pressure needed to overcome a resistance of the selection of each of the full gears. The slight delay this causes is not a real problem in the higher gears at faster road speeds, but in the lower half of the box the problem becomes exaggerated as these are the gears that need to be selected quickly if the vehicle is to avoid coming to a stop when climbing steep hills. This is exacerbated by the detent separating the low and high ranges.

The downchange from 5th to 4th is invariably made when forward momentum is reducing rapidly, and that extra moment needed to pass through the detent usually precludes the choice of selecting 4th gear.

Split ratios, however, could be chosen at will; they are preselected using the lever-mounted switch with the change tak

ing only the time needed to depress the clutch pedal fully. In practice there is plenty of power in hand as 3rd-low was the lowest gear needed to climb the steepest hill on our test route.

On the flat second can be used from a standing start, followed by fourth and then fifth before it becomes preferable to use split gears for optimum acceleration. A warning lamp is included in the binnacle to indicate engagement of the low range, but it is obscured by the steering wheel rim and there is nothing to tell the driver when the split is taken. Nonetheless, having selected the full gear it becomes automatic to preselect the splitter ready for the next up or down change.

Restarting on hills poses another problem. At MIRA we were unable to move away on any slope steeper than 20% due to lack of traction on the drive axle. Even with the difflock engaged we were at the

limit and could only move away with both wheels spinning.

• BRAKING

During track tests braking distances were long and overall deceleration rates low. The Motometer chart indicated a slow build up, taking about 0.5sec to reach a peak of just over 0.6g under maximum pedal application.

None of the wheels locked and the vehicle pulled up in a straight line. Using much lighter pedal applications during normal driving the delay cannot be detected, but the brakes are slow to release.

The exhaust brake provides a useful check to roadspeed on downhill gradients when used in conjunction with a gear ratio lower than top. The foot-button control is conveniently sited and pulls back the rack to cut off the fuel: a short delay in the release momentarily leaves the driver with a hard throttle pedal

If the clutch is depressed to make a gear change after using the exhaust brake there is a delay, but it is not long enough to kill the engine — which is an improvement over the more powerful 190.42. (CM 6 August 1987), Steering is light but positive and it is easy to apply full lock at low speed. Turning circles are about average for this size of tractive unit, but when we applied full left lock the clamp bolt at the end of the tie bar scraped the base of the nearside shock absorber. Adequate clearance was re-established by rotating the clamp through 1800 to its correct position.

• CAB COMFORT

The full-width Turbostar cab is well insulated, and so little noise intrudes from the engine, transmission or wheels that wind noise around the front corners becomes more prominent.

The high-backed, air-suspended driver's seat offers a good range of adjustment for height, weight, reach and rake, and is complemented by the adjustable steering wheel which offers 10° of rake and 100mm of vertical movement,

Internal trim is light and many of the surfaces across the front bulkhead and on the doors can be easily wiped down. The floor wells, covered in thick rubber matting, are also easy to keep clean as they finish flush with the door sills.

At the centre of the cab the fascia protrudes back above the engine hump, bringing a row of switches within easy reach and housing the ventilation and air conditioning controls. Annoyingly, the headlight switch, used frequently to flash-in overtaking vehicles, is awkwardly sited on the column below the steering wheel.

By compuision with the large windscreen, the door windows are small and the louvred windows to the rear of the B-post offer only restricted visibility. Both door windows and the large heated exterior mirrors are electrically powered for adjustment. Mirror wipers seem a good idea although these examples failed to wipe the lenses clear, but the big screen wipers did give a dean sweep.

For day use the top bunk folds up against the rear bulkhead to create a feeling of extra roominess. Storage space is included in the centre console for paperwork; pouches are fitted to the doors and a strongbox is concealed below the lower bunk. Two lockable compartments in the header rail are provided for the radio cassette and CB transceiver.

Our test vehicle, some six months old, was already showing signs of use. The trim above the passenger door was loose, and holes securing the elastic straps across the front of three header rail shelves were worn.

Front blinds pull down to meet side curtains and offer privacy for overnight stops; a wardrobe section is included at the head of the bunk, but it is next to the window where clothes could become cold over night. Curtains behind the seats enclose the sleeping area and reading lamps are provided for both bunks.

Outside, the cab is fitted with a polyurethane bumper, lower spoiler, steps, mudguards, corner deflectors and front grille, which lifts up on gas-filled stays to give access to daily service points for oil, coolant, clutch fluid and water reservoirs. To reach the engine the cab can be raised hydraulically through 65°.

Running with Iveco Ford's CF air-suspended trailer can only have improved the ride characteristics. Normally we road test with our own CF steel-sprung semitrailer, fitted with large concrete blocks that are bolted down. Had we used it with the 190.36 tractive unit, which weighs 7.4 tonnes, we would have been overweight unless we had removed some of the load and repositioned the remainder.

The air-suspended trailer has a 1.6m pin position and we coupled with an overall length of 15.4m, but we are told it is possible to couple legally to the standard 1.2m pin position where a sliding fifth wheel is fitted.

• SUMMARY

The 190.36 Turbostar falls into the most popular operational power category at 38 tonnes. Its combination of high power output at low revs and high torque makes it very relaxing to drive, and it returns good fuel consumption at average speeds.

ZF's 16-speed gearbox with its doubleH gate is not as slick as we would like, especially when it has to cope with severe .hills and the brakes were unimpressive during track tests, although they seem quite adequate for normal road use.

Restarting can just be managed on a 20% gradient: the engine is willing, but limited by insufficient traction.

Average journey times and good fuel consumption partly confirm Iveco Ford's productivity claims, but at 7.4 tonnes with a spare wheel, offset to some degree by aluminium wheels, the 190.36 is heavy compared with most of its competitors which average about seven tonnes.

III by Bill Brock