THE NEW

Page 44

Page 45

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

SCAMMELL EIGHT-WHEELER

THE new Scammell articulated eight-wheeler with low-pressure tyres, of which the following is the first account to be published, is regarded by its designers as something in the nature of a culmination in Scammell design. In the first place, the vehicle can legally carry a 14-ton pay-load. Like its prototype from the works of Scammell Lorries, Ltd., Watford, which had the four carrier wheels in line on two short rocking axles, it is built for 17 tons, so that for special work it can easily cope with such burdens. Our test, occupying nearly three days last week, was conducted with the legal pay-load of 14 tons, but we also measured fuel consumption when carrying 17 tons.

The main dimensions of the outfit are:—

Overall length, 33 ft.; overall width, 7 ft. 6 ins.; bogie track, 6 ft, 11 in.; driving-wheel track, 5 ft. 8 ins.; carrier unit wheelbase, 13 ft. 6 ins, to bogie centre; motive unit wheelbase, 10 ft.; carrier-bogie wheelbase, 4 ft. 2 ins.; floor height (laden), 4 ft. 6 ins.; rear overhang, 7 ft. 8 ins, from bogie centre; maximum carrier-frame section,. 16 ins. by 3i ins, by f in.•' approximate axle weights (front to rear), 2 tons, 8 tons, 6 tons, 6 tons.

The standard features of the Scammell eight-wheeler are retained and are, of course, familiar to our readers. The new carrier bogie is of the type embodying an Inverted semi-elliptic spring on each side; the springs are pivoted beneath massive brackets welded to a crossmember which is bolted to the frame. The crossmember is made from two 8i-in, by 34n, channels, welded lengthwise, and the two ends are sealed by fin.

welded plates. B26

Each spring chair is split diagonally, the two parts being held together by two pairs of large bolts 8 ins. apart, which give them a powerful grip upon the four spring leaves. To obtain full benefit of this grip the leaves, which are 6 ins, wide and I in. thick, are ground at their sides. This prevents lateral pivoting, which is a very bad thing with a bogie of this kind. The pivot pins are of case-hardened steel, 2i ins. in diameter, their bushes being 11 ins. long.

The wheels are fitted, with two Timken bearings, upon h011ow axles of lf in. inner and 31 ins, outer diameters. Each hub supports the spring end at two places through a cast-steel bracket. The spring-end bolt has a shoulder and passes through the two longest leaves, the shoulder permitting the second leaf, which has a slotted hole, to slide upon the main leaf, but affording support to the load should the main leaf break. To prevent judder with sudden application of the brake an adjustable stop on an upper shoulder of the spring-end bracket butts against the top surface of the third leaf. So as to allow for relative movement between the fore and aft wheels on each side of the bogie, the brake cable is connected to the centre of a floating link.

A most important feature is the tyre equipment. The Scammell Co. has found that with the low-pressure tyre the rolling resistance is actually lest than with tyres of higher pressure. The reason, as demonstrated during our test, is that the low-pressure tyre rolls over larger bumps and " absorbs " smaller ones instead of climbing and bouncing. This results in greater speed and less fuel consumption. There is an advantage over

dual high-pressure tyres in that road camber and other influences do not cause momentary 100 per cent, overloads due to one tyre being off the ground.

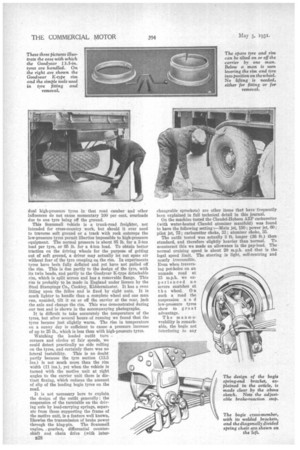

This Scammell vehicle is a trunk-road freighter, not intended for cross-country work, but should it ever need to traverse soft ground or a track with rock outcrops the low-pressure tyres permit liberties impossible to high-pressure equipment. The normal pressure is about 85 lb. for a 3-ton load per tyre, or 95 lb. for a 4-ton load. To obtain better traction on the driving wheels for the purpose of getting out of soft ground, a driver may actually let out spme air without fear of the tyre creeping on the rim. In experiments tyres have been fully deflated and yet have not pulled off the rim. This is due partly to the design of the tyre, with its twin beads, and partly to the Goodyear K-type detachable rim, which is split across and has a removable flange. This rim is probably to be made in England under licence by the Steel Stampings Co., Cookley, Kidderminster. It has a cone fitting upon the felloe and is fixed by eight nuts. It is much lighter to handle than a complete wheel and one man can, unaided, tilt it on or off the carrier at the rear, jack the axle and change the rim. This was demonstrated during our test and is shown in the accompanying photographs.

It is difficult to take accurately the temperature of the tyres, but after several hours of running we found that the tyres became just slightly warm. The rise in temperature on a sunny day is sufficient to cause a pressure increase of up to 25 lb., which is less than with high-pressure tyres.

Watching the loaded outfit turn corners and circles at fair speeds, we could detect practically no side rolling on the tyres, and certainly there was no lateral instability. This is no doubt partly because the tyre section (13.5 ins.) is not much more than the rim width (11 ins.), yet when the vehicle is turned with the motive unit at right angles to the carrier unit there is distinct flexing, which reduces the amount of slip of the leading bogie tyres on the road.

It is not necessary here to explain the design of the outfit generally ; the suspension of the turntable on the driving axle by load-carrying springs, separate from those supporting the frame of the motive unit, is a feature well known, likewise the transmission of brake power through the king-pin. The Scammell engine, gearbox, differential countershaft and chain drive (with inter

B28 changeable sprockets) are other items that have 'frequently been explained in full technical detail in this journal. On the machine tested the Claudel-Hobson AZP carburetter (with water-heated Claudel atomizer manifold) was found to have the following setting :—Main jet, 150; power jet, 60; pilot jet, 75; carburetter choke, 33; atomizer choke, 35.

The outfit tested was actually 3 ft. longer (36 ft.) than standard, and therefore slightly heavier than normal. To counteract this we made an allowance in the pay-load. The normal cruising speed is about 20 m.p.h. and that is the legal speed limit. The steering is light, self-centring and nearly irreversible. Even when traversing pot-holes on an unmade road at 15 m.p.h. we experienced no severe snatches at the wheel. On such a road the suspension a n d low-pressure tyres show to great advantage.

The mancenvrability is remarkable, the bogie not interfering to any the carrier to overhang the footpath. On a slippery road of acute camber there is little or no tendency for the carrier wheels to slide towards the kerb.

The acceleration and braking capabilities are revealed by accompanying graphs. The effect of a wet road upon either is almost negligible, due to the excellent tyre grip. The acceleration is adequate for this class of outfit, the power at low engine speeds being a good point.

As regards braking this could be rendered more responsive by power application in one form or another, but the Scammell concern is not satisfied with tests so far made in this respect. Any two of the three brakes easily held the 22 tons on Cocks Hill (on the Barnet-Elstree road), which has a gradient of about 1 in 6, whilst on Brockley Hill (about 1 in 9) any one brake separately held the vehicle.

We satisfied ourselves that the outfit with a 14-ton payload would climb Cocks Hill, with its 1-in-6 gradient. The ascent was made frond rest, second gear being used for the early part of the climb and first gear for the steep section. The time was 104 secs., making the average speed 4 m.p.h. Brockley Hill (440 yds., average gradient 1 in 11, maximum 1 in 9). was climbed from the south in second and first gear in 3 mins. 20 sees., the speed averaging 4.5 m.p.h. The same hill was climbed from the north side entirely in second gear in 2 mine. 36 secs., giving an average speed of over 8 m.p.h.

With 14 tons and with 17 tons of pay-load the northward climb in Tring High Street was negotiated easily on second gear. The Aston-Clinton hill, travelling southward, was climbed in third and second gears, the climb from Watford up to Bushey Heath calling for first gear. These readings are sufficient evidence of a first-rate performance on hills. There was no sign of overheating. In fact, on days when the air temperature was between 47 degrees and 60 degrees it was necessary to blank off part of the radiator in order to keep the engine adequately warm.

On the 1-in-10 section of 13rockley Hill we found it easy to effect a restart on first gear, and this was tried several times on similar hills, the cone-type clutch acting sweetly.

For testing fuel consumption we parked the outfit at a marked spot and filled the dashboard tank to the top of the neck ; we afterwards returned to the same spot and refilled from gallon and pint measures. The test journey was from Watford to Aylesbury and back via Tring, exactly 50 miles. Our speed on this journey averaged 19.35 m.p.h. and the fuel consumption was at the rate of 5.97 m.p.g. To obtain readings with the full rated load of 17 tons we added 3 tons and repeated the test, the results then being 18.18 m.p.h. and 5.63 m.p.g. On the hills encountered and in other respects the performance was scarcely affected by the extra 3 tons.

It should be explained that for regular use with 14 tons 18-toothed instead of 17-toothed driving sprockets can be fitted. This improves the fuel consumption to about 6.25 m.p.g., a figure which shows remarkable economy. This new Scammell model, with its large legal carrying capacity, low operating cost and excellent performance, appears to have a promising future, for it solves many of the problems of long-distance trunk-road haulage in these difficult times. It enables the big load to be carried with speed, economy and—a clear consciencb.