A horse for a course

Page 69

Page 70

If you've noticed an error in this article please click here to report it so we can fix it.

MODERN body-building techniques offer such a wide range of body shapes and sizes, together with a mass of mechanical aids, that there is little excuse for an operator using a vehicle not ideally suited for the traffic he intends it to carry.

There are cases of obvious misuse, such as powders which can be subjected to atmospheric pollution being carried on open platform lorries or impervious smalls traffic like aerated waters being carried in a closed-in van.

When ordering a 30-guineasuit an operator specifies refinements which he considers suitable and desirable. However, when ordering a £2,000 vehicle he frequently has one -off the peg". It's too easy to say "same as last time" without giving the matter any thought. The additional expense involved in ordering a custom-built vehicle is soon recouped by savings in operational costs,

It is to the advantage of both builder and customer to have an accurate specification. How to achieve this can best be understood if we examine what the vehicle is going to be used for.

Naturally requirements differ for each operator and type of load, but all who carry goods must do so economically and safely.

The data required in order to arrive at a sound specification is: The answers to these questions result from past experience or information supplied by the haulier's customer. In the following I am looking at three work specifications in order to arrive at an ideal body specification.

First consider work specification No. 2. Sticky powder in bulk has to be transported and the nature of the load precludes the use of any air-pressure system on the vehicle. No power is needed since off-loading is done by equipment at the terminal point. Thus an articulated body is suitable and operation will be on a merry-go-round principle (using three trailers). As underground extraction is employed the body will require large discharge openings in the floor, so shaped that the maximum amount of load can pass easily without build-up.

But the facts in example 1 are quite different. First of all, the load is dry powder in bulk, the answer of "empty" for return loading need only apply if suitable traffic is not available and this would appear likely. As the discharge is by automatic means then it should be .Jpeec"{ and therbfore the three-trailers System is inappropriate.

Example. 3 is a straightforward delivery routine. However, is the loading and offloading by hand satisfactory? Can turn-round time be reduced ? Should the load be palletized and if so should the body be equipped with a simple, hand-operated pallet loader? If so, then this should be included in the specification.

Local delivery forms a large percentage of road transport, and one stumbling block is off-loading in congested areas, using a standard van body. This causes loss of productivity and is dangerous.

The following work study example shows clearly the relationship between the body design and economical and safe operation. I-laving stopped the vehicle at the kerb in front of a store the driver :

1 Opens the van door and steps out of the cab, in the direct path of oncoming traffic. (Unsafe.) 2 Moves along the off-side of the van. (Unsafe.) 3 Opens the rear shutter and drop tailboard.

4 Lifts out a two-wheeled truck on to the pavement.

5 Climbs into the van with the aid of a centre hanging rope.

6 Moves the required goods to the rear edge of the van. (First handling.) 7 Jumps down from the body.

8 Loads goods on to the two-wheeled trolley (second handling) and makes delivery into store (third handling).

9 Returns the two-wheeled truck to the van floor.

10 Closes up the rear of the body.

11 Makes way back to cab door on the off-side. (Unsafe.)

12 Opens cab door (unsafe), starts up and moves off.

Much of this unsafe and energy sapping operation could have been avoided by simple pre-planning. The use of a single-level floor from cab to van, with a half-bulkhead directly behind the driver, and access from cab to body would reduce the unsafe. element. A rear-end step, either as part of the floor construction or as folding units, operated by the dropping of the tailboard, plus the use of a transparent or translucent roof construction to allow the maximum of natural light into the body, would reduce much of the physical effort required.

Alternatively, side door unloading may be preferable to rear-loading, the decision depending largely on the actual traffic conditions encountered in at least 80 per cent of the drop-off points.

Loads such as motorcycles, crated machinery, lawn mowers, gas bottles, tyres, wheels in quantity and certain palletized loads not affected by bad weather conditions can well be transported in semi-open bodies. These are constructed as flat platforms with corner pillars and lightweight roofs. The sides and back are built up from expanded metal or heavy-duty wire mesh on steel frames. Alternatively the sides can comprise a series of removable stakes, set at intervals dependent upon the load. This type of bodywork has been becoming increasingly popular in the past two years.

For the building trades, local milk and bread delivery and for special loads, a part-open body should be considered. Such designs allow the forward end to be closed to accommodate goods needing protection, while the rear is either an open flat with a lightweight roof, or a fully open area bounded by low drop-sides and tailboard.

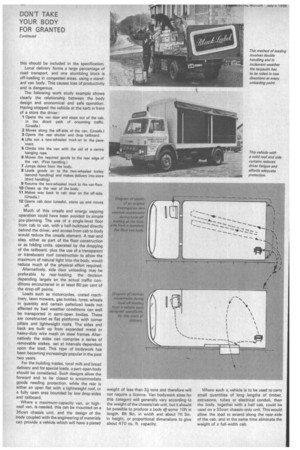

Where a maximum-capacity van, or highroof van, is needed, this can be mounted on a 35cwt chassis unit, and the design of the body coupled with the engineering of materials can provide a vehicle which will have a plated

weight of less than 3+ tons and therefore will not require a licence. Van bodywork sizes for this category will generally vary according to the weight of the chassis/cab unit, but it should be possible to produce a body of some 10ft in length, 6ft 9in. in width and about 7ft 3in. in height, or proportional dimensions to give about 470 cu. ft. capacity. Where such a vehicle is to be used to carry small quantities of long lengths of timber, extrusions, tubes or electrical conduit, then the body, together with a half cab, could be used on a 35cwt chassis-only unit. This would allow the load to extend along the near-side of the cab, and at the same time eliminate the weight of a full-width cab.