A P.RIZE OF TEN SHILLINGS is awarded each week to

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

the sender of the best letter which we publishon this page; all others paid for at the rate of a penny a line, with an allowance for photographs. All notes are edited before being published. Mention your employer's planis, in confidence, as evidence of good faith. Address D. M. and F. The Commercial Motor," 7-15, 1-?osebery Avenue, London, E.G.

Vamps Alight.

Light your larn.ps at 9.46 in London, 10.55 in Edinburgh, 10.12 in Newcastle 10.8in. Liverpool, 9.58 in Birmingham, 9.56 in Bristol, and'10.51 in Dublin.

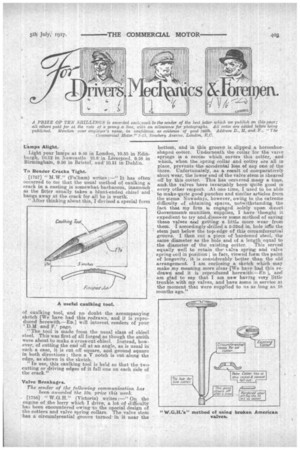

To Render Cracks Tight. • [1757] " M.W." (Fulham) writes :—" It has often occurred to me that the usual method of caulking a crack in a casting is somewhat barbarous, inasmuch as the fitter usually takes a blunt-ended chisel and ' bangs away at the crack for all he is worth. "After thinking about this, I devised a special form of caulking tool, and no doubt the accompanying sketch [We have had this redrawn, and it is reproduced herewith.—En.] will interest readers of your • D.31 and F.' page.

"The tool is made from the usual class of chisel steel. This was first of all forged as though the smith were about to make a cross-cut chisel. Instead, however, of cutting the end off at an angle, as is usual in such a case, it is cut off square, and ground square in both directions ; then a V notch is cut along the edge, as shown in the sketch.

In use, this caulking tool is held so that the twocutting or driving edges of it fall one on each side of the crack."

Valve Breakages.

The sender of the following communication has been awarded the 10s. prize this week.

[1758] " W.G.H." (Victoria) writes :—" On the engine of the lorry which I 'drive, a lot of difficulty has been encountered owing to the special design of the cotters and valve spring collars. The valve stem has a circumferential _groove turned in it near the bottom, and in this groove is slipped a horseshoeshaped cotter. Underneath the collar for the valve springs is a recess which coy era this cotter, and which, when the spring collar and cotter are all in place, prevents the accidental loss of any one of the three. Unfortunately, -as a result of comparatively short wear, the lower end of the valve stem. is sheared off by this cotter. This has occurred many a tune, and. the valves have invariably been quite good in every other respect. At one time, I used to be able to make quite good punches and similar articles from the sterns Nowadays, however, owing to the extreme difficulty of obtaining spares notwithstanding the fact that my firm is engaged solely upon direct Government, munition_ supplies, I have .thooght it expedient to try and, discover some method of saving these valves and getting a little more wear from them. I accordingly drilled a 5-32nd in. hole irfto the stem just below the top• edge of this circumferential groove. I then cut a piece of hardened steel, the same diameter as the hole and of a length equal to the diameter of the existing cotter. This served equally well to -retain the' i alve spring and valve wing coil in position ; in fact, viewed form the point of longevity, it is considerably better than the old arrangement. I am enclosing a sketch which may make my meaning more Clear [We have had this redrawn and it is reproduced herewith:—En j, and aril glad to say that I am new having very little trouble with my valves, and have some in service at the moment that were supplied to us as long as 18 months ago."