Perkins Produce E

Page 60

Page 61

Page 62

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

r,orous "Baby"

Four 99 1.6-litre Oil Engine in Thames 10-12-cwt. Van Shows High Economy and Lively Performance : Easy Starting and Quiet Running

By John F. Moon, A.M.I.R.T.E.

OIL engines for delivery vehicles of down to 1-ton capacity have been established for several years, but lighter vans of between 10and 15-cwt. capacity, which normally. use 'private-car components, have until recently been left behind in this field. The principal reason Was •that the smallest available oil engines—over 2 litres— were too big and expensive, with unnecessarily high outputs for such vehicles.

The introduction last April of the Perkins Four 99 1.6-litre oil engine threw a new light on the possibility of converting light vans to oil-engine power, as it has generally similar box dimensions to the type of petrol engine normally fitted, and its power characteristics are closely matched..

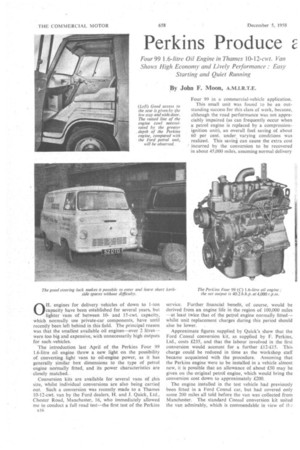

Conversion kits are available for several vans of this size, whilst individual conversions are also being carried out. Such a conversion was recently made to a Thames 10-12-cwt. .van by the Ford dealers, H. and J. Quick, Ltd., Chester Road, Manchester, 16, who immediately allowed me to conduct a full road test—the first test of the Perkins Four 99 in a commercial-vehicle application.

This small unit was found to be an outstanding success for this class of work, because, although the road performance was not appreciably impaired (as can frequently occur when a petrol engine is replaced by a compressionignition unit), an overall fuel saving of about 60 per cent. under, varying conditions was realized. This saving can cause the extra cost incurred by the conversion to be recovered in about 45,000 miles, assuming normal delivery

service. Further financial benefit, of course, would be derived from an engine life in the-region of 100,000 miles —at least twice that of the petrol engine normally fitted— whilst unit replacement charges during this period should also be lower. .

Approximate figures supplied by Quick's show that the Ford Consul conversion kit, as supplied by F. Perkins, Ltd., costs £235, and that the labour involved in the first conversion would account for a further £12-£15. This charge could be reduced in time as the workshop staff became acquainted with the procedure. Assuming that the Perkins engine were to be installed in a vehicle almost new, it is possible that an allowance of about £50 may be given on the original petrol engine, which would bring the conversion cost down to approximately £200.

The engine installed in the test vehicle had previously been fitted in a Ford Consul car, but had covered only some 200 miles all told before the van was collected from Manchester. The standard Consul conversion kit suited the van admirably, which is commendable in view of th.! rather small engine aperture in the cab seat box which is a feature of this Ford design.

Indeed, two fitters took only a day to exchange engines, with a further day devoted to modifying the lower panelling of the standard engine cowl. Its depth was increased by some 5 in., and two extenSions were incorporated on the left-hand side to give clearance for the fuel filter and the exhaust-manifold outlet.

Otherwise, the standard van components were retained, with the exception that the twin vacuum-operated windscreen wipers we.re replaced by a single-blade electric wiper. Because of the necessity of reducing the overall height of the engine, the top water-hose shape was altered slightly, which entailed cutting 2 in. off the fan blades to give sufficient clearance between the bottom of the hose and the blade tips.

Much of the modification required on the cowl in the case of this initial conversion can, it is hoped, be eliminated by mounting the fuel filter in a lower position on the engine, using an exhaust manifold with a forward outlet, and locating the air cleaner away from the engine with a flexible hose connection to it. This would then allow the standard Ford engine-cowl panelling to be retained and so reduce the labour required.

With the exception of the unfamiliar -power unity the van was in standard condition. This Model, which was introduced on November 1, 1957, marked a complete departure by the Ford Motbr Co., Ltd., from their previous practice in light commercial vehicles. Although externally it is little bigger than the semi-forward-control 10-cwt. Van which it replaced, the payload space is almost 50 per cent. greater because of the forward-control driving position.

The standard specification includes the Ford Consul 52 b.h.p. four-cylindered petrol engine, three-speed gearbox with steeringcolumn change, hypoid-bevel rear axle, separate chassis frame, and coilspring independent front suspension. The 10-12-cwt. van is almost identical to the 15-cwt. version, the principal . differences being in respect of tyres, rear springs and axle ratio.

As offered for test, the van had a kerb weight of 1 ton 2 cwt. Payload provided by Quick's consisted of one large and one small wooden crate containing used car engines, these adding up to I1+ cwt, Thus, with myself and passenger aboard, the full-load tests were conducted at a gross running weight of 1 ton 171 cwt.

Full Series of Tests

Although the object of borrowing the vehicle was primarily to assess the engine performance, I elected to carry out a full series of tests.

Initial braking tests were made on a Wet road and the van stopped safely in 21.5 ft. from 20 m.p.h., but later figures obtained on a dry surface Showed the brakes to reach a high standard. Realizing that the• front wheels carry a greater proportion of the total weight than those at the rear, the designers have provided larger brakes at the front.

nfortunately, this particular vehi e, which had covered about 5,000 miles in normal service, had developed a hand-brake fault-possibly a stretched cable-with the result that only 25 per cent. efficiency couldbe obtained by applying the hand brake from 20 m.p.h. The position of the brake lever, however, affords good purchase, and, had the linkage been in order, at least 40 per cent. would have been yielded by it from this speed.

Good Acceleration

Acceleration tests revealed a surprisingly good performance through the gears, particularly with a threespeed gearbox, and the times obtained are better than often recorded with petrol-engined vehicles of this capacity or even less. First gear was employed up to about 25 m.p.h. and second engaged until just over 45 m.p.h. was reached.

Because of the relatively high rearaxle ratio direct-drive acceleration was a little more subdued, and figures could be taken only from 20 m.p.h. upwards, instead of from the usual 10 m.p.h. At 15 m.p.h. the engine speed was reduced to its normal idling rate and the vehicle could not be driven at a lower speed with top gear engaged.

Nevertheless, the direct-drive times obtained between 20 M.p.h. and 40 m.p.h. show that the engine can pull in this gear, although a certain amount of vibration and body drumming was experienced at up to 25 m.p.h. In normal service drivers are unlikely te use top gear below about 25 m.p.h. and certainly in towns, where traffic is dense, second gear will be the ratio most frequently employed, this giving good results between 10 m.p.h. and 40 m.p.h.

Two sets of fuel-consumption figures were obtained on the six-mile undulating course along the AG road between Barton and Clophill. The first series of tests was made at the full weight and consisted of runs made non-stop, with one stop per mile and with four stops per mile. These three performances were then repeated with the gross weight reduced by 4 cwt., it being impossible to take off more of the payload because of the weight of the large packing case.

Excellent Fuel Economy

The fuel-consumption figures were obtained by driving at 30-35 m.p.h. whenever road conditions would allow and normal acceleration rates were used when pulling away from stops. The results show excellent economy and, had it been possible to make a non-stop run with all the payload removed, it is reasonable to suppose that a rate of at least 56 m.p.g. would have been yielded.

Further engine-power figures were obtained up the 4-mile Bison Hill, adjoining Whipsnade Zoo, which has an average gradient of I in 10-1. A climb made in an ambient temperature of 46°F. took 2 minutes 25 seconds, bottom gear being engaged for 371 seconds. The engine coolant temperature rose from 170°F. to 193° F., but the system is pressurized to 7 p.s.i. to raise the boiling point, so there should be a satisfactory cooling margin for full-load work in hilly areas.

To test for brake fade, the van was then coasted down the hill in neutral, except that on the lower slopes, where the gradient is not severe, top gear was engaged and the van driven against the brakes at full throttle. This test lasted for 2 minutes 40 seconds.

At the end of the descent the foot brake was applied and a Tapley meter reading of 82 per cent. recorded. As this is slightly higher than maximum reading recorded when making the normal brake stops it is safe to assume that fade will not be a worry.

Returning to the steepest section, where the gradient is 1 in 61, •the van was stopped and at this point the hand brake held it satisfactorily. A firstgear restart was then attempted. but only by slipping the clutch excessively was it possible to get away, accom

panied by a certain amount of black smoke from the exhaust outlet.

Farther up the hill, where the gradient is 1 in 7, a restart was made reasonably satisfactorily. This appears to be the maximum gradient on which a restart can be attempted when carrying a full load with the standard 4.11to-1 axle. If operation in very hilly areas is contemplated, the optional ratio of 4.62 to 1 would be advisable.

The road performance a the van generally is entirely satisfactory. Particularly noteworthy features of the engine installation are the low volume of noise and the little vibration detectable in the cab.

Although with the cowl raised the engine cannot by any means be termed quiet, the standard cowl insulation absorbs extraneous engine noises. The engirre mounting rubbers, although inclined to be hard, almost completely eliminate vibration of the frame and bodywork, even when the unit is idling.

The engine is quietest when pulling hard and when overrunning, but, even so, only slight " rattle " is heard from it under part-throttle. Only when accelerating hard and using the full range of the engine speed does noise become obtrusive.

Having originally been supplied for a car conversion, the unit fitted in the van was governed to 4,000 r.p.m., whereas. the standard engine offered by Perkins for goods vehicles is restricted to 3,600 r.p.m. This makes little difference to the gross and net power outputs, but the extra 400 r.p.m. available is a decided help, particularly when accelerating, and I would recommend that any conversion engine applied to a van of this size should be ordered with the higher speed.

Top Speed of 70 m.p.h.

Furthermore, the top speed is raised to about 70 m.p.h. The hydraulic governor of the DPA pump is effective throughout the speed range, with a noticeably sharp cut-off proportional to throttle-pedal position.

Cold starting at temperatures down to 36°F. was accomplished without difficulty by using the Thermostart for 10 seconds and then, while keeping the button depressed, cranking the engine over for a further 5 seconds. Although recommended by the engine manufacturers, a larger-capacity battery had not been installed when the conversion was made and the standard 45-amp.hr battery appeared to be sufficient for normal cranking purposes.

Like the standard Ford petrol engine, the Perkins is not easily accessible. The forward-hinged bonnet takes 6 seconds to raise and with this up I was then able to check the radia

tor-water level in 7 seconds, the engine-oil in 24 seconds and the aircleaner oil level in 50 seconds.

Using the special semi-box-spanner provided by Perkins I removed No 2 fuel injector in 6 minutes and replaced it in 91 minutes. To do this it was necessary to remove the return pipe from No. 1 injector also, so that it could be pulled clear of the injector I was removing.

Collar Nut Retained

Difficulty was experienced because the left-hand-thread collar nut which retains the injector in the cylinder head was tight, presumably because of burnt oil and carbon. When tightening the collar nut it tends to rotate the injector away from its correct position, and this necessitates holding it to ensure reasonably easy replacement of the feed and return pipes.

With the fuel filter in its present position the bowl can be detached for element removal only by taking off the left-hand lower cowl panel. This is secured by nine self-tapping screws, which tend to lengthen the time of element replacement, although fortunately this is not a job requiring to be done frequently.

Access to the DPA fuel-injection pump baffled me completely, the pump being low on the left of the engine. 1 assume that the best way to reach it is to remove the near-side front wheel and part of the wheel-arch panelling. '

The gearbox oil level was checked in 40 seconds, there being a combined filler and level plug in the left side of the casing. A similar plug in the rear axle enables this level to be verified in a minute.

The single hydraulic-fluid reservoir for the brakeand clutch-actuation circuits lies beneath the driving seat. and by sliding the seat forward this level was checked in 14 seconds.

Brake adjustment proved to be reasonably simple, there being two square-headed adjusters to each front brake and one to each rear brake. Because the van was laden I had to jack up each wheel in turn, rather than both front wheels and both rear wheels simultaneously, so each front brake took 31 minutes to adjust and each rear brake 21 minutes.

The spare wheel is carried beneath the floor, behind the rear axle, and it is suspended from a pivoting arm which may be lowered to ground level with the aid of the wheel-brace. The actuating nut is reached by lifting the " Thames " nameplate beneath the rear doors. So simple is the arrangement that I removed the spare wheel in 15 seconds and restored it in the same time.