Volvo Can Take it!

Page 57

Page 56

Page 58

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

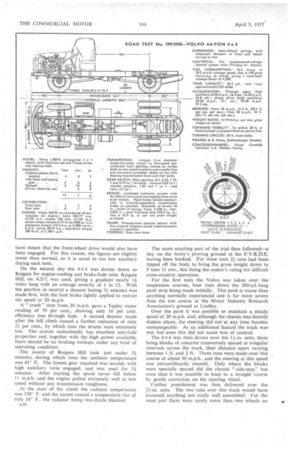

By John F. Moon, A.M.I.R.T.E. THE use of medium-capacity cross-country vehicles for civil engineering has never been fully exploited in Great Britain for various reasons, mainly financial. In other parts of the.world, however, much greater use is made of all-wheel-drive vehicles by civilian operators, and Sweden is no exception in this respect. The Volvo L38545, a 4-6-ton 4x4, is now being marketed in . Great Britain by the Volvo commercial-vehicle concessionnaires, Victor (Swedish Vehicles), Ltd.

' This is not a military chassis: Volvo vehicles built for the Swedish forces haVe different specifications. For that reason great credit is reflected on the ability of the design. to stand up to 'the battering it received on the Ministry of Supply's F.V.R.D.E. test courses during one day Of 'a recent three-day test.

Robust and Powerful . .

These specialized tests revealed the robustness and power of the chassis. Running at 9 tons '11 cwt. gross, the Volvo scaled a 1-in-2 gradient, ran three miles at high speed over the harshest suspension-test courses in the country, and successfully negotiated the worst of the famous Alpine _rough-country course at Bagshot. The only mechanical signs of such treatment were a strained bonnet hinge, a loose bolt on the throttle linkage and another on the winch-engagement lever.

A Volvo D67A six-cylindered oil engine powers the 138545 chassis; it is used also in 7-ton 4 X 2 vehicles in the standard Volvo range. It has generous working surfaces to give long life, and particular attention has been paid to thorough fuel, air and oil filtering, as becomes a vehicle destined to work "in the rough."

A five-speed gearbox is unit-mounted with the engine. The chassis tested had the K12 box with overdrive top, but as an alternative the K13 gearbox can be fitted. This has ratios of 7.72, 4.08, 2.18, 1.41 and 1 to 1, with a 7.59 to 1 reverse gear, and is therefore more suitable for continuous off-the-road haulage. Both gearboxes ' have synchromesh on all but bottom and reverse.

The drive then passes through a short cardan shaft to the auxiliary and transfer box. This box is unusual in that there is no provision for power-take-off gears. When a power take-off is required it can be taken _ from the side of the main gearbox, as in the case of the winch drive of the test chassis, but full engine torque cannot be delivered.

016

A feature of the auxiliary transmission, frequently found on American vehicles, is that there is no separate lever for front

wheel-drive engagement. Instead, this is automatically engaged when low auxiliary ratio is in use, thus safeguarding against the possibility of transferring too much torque through. the rear axle.

The chassis frame is of 1-in. steel pressings, with riveted alligator-jawed crossmembers. The top and bottom flanges of the side members are 3/ in. wide and carry riveted reinforcing plates for the greater part of their length. The maximum frame depth is 9 in.

Hypoid-bevel final-drive gearing is used in both axles, although the two are not interchangeable, and the front axle has Rzeppa constant-velocity joints enclosed in .rubber gaiters: Additional protection is provided by pressed-steel shields attached to the brake back-plates. The front-wheel lock is exceptional for a 4x4 ehassis. Conventional semi-elliptic springs are used, with separate helper units at the rear axle, and heavy-duty telescopic dampers are available as extra optional equipment for the front suspension. Such dampers were fitted to the test chassis, and their great length contributed in no small way to the remarkable stability of the vehicle over the military test courses.

Lockheed hydraulic brakes are employed, with twoleading-shoe units at both axles, and the test vehicle had a Bosch air-pressure system working an Air-Pak servo. This servo is similar to the vacuum-operated Hydrovac servo, which is available as optional equipment, and gives powerful braking.

The chassis. had left-hand drive, this being standard in Sweden (right-hand drive can be supplied), and a standard Nystrom all-steel three-man cab was fitted. The Tranas three-way tipping body was non-standard. This had twin underbody hydraulic rams and the body was secured by four simple screw-actuated locking pins, which gave complete security over rough country. The cab, body and tipping gear weighed approximately 2 tons.

Five tons of coarse chippings were loaded and 30 1-cwt. iron blocks were then placed on top to bring the gross weight to 12 tons 1 cwt. with driver and two passengers.

For the first test—fuel-consumption—the Volvo was taken out to the northern end of the Kingston By-pass. Here the fuel test tank was filled and I drove for 18 miles, turning round at the start of Hampton Court Way. The average figures for the 18-mile out-andreturn circuit are 12.2 m.p.g. and 29.2 m.p.h., giving a time-load-mileage factor of 4,300, which is reasonable for a multi-wheel-drive vehicle running at 12 tons gross.

An ambient temperature of 35° F. was recorded during these fuel tests, but by keeping the radiator blind fully raised the coolant was maintained at 185° F.

Brake and acceleration tests were conducted along a level stretch of the Hampton Court Way. Braking efficiency was such as to cause large quantities of gravel to be showered over the cab and roadway each time the brakes were applied fully. The servo delay in the system accounted for a difference of 15 per cent. between the maximum and average deceleration figures.

Acceleration tests were made with the direct-drive auxiliary ratio engaged, because to use low ratio would 1317 have meant that the front-wheel drive would also have been engaged. For this reason, the figures are slightly lower than normal, as it is usual to use low auxiliary during such tests.

On the second day the 4 X 4 was driven down to Reigate for engine-cooling and brake-fade tests. Reigate Hill, on A217, was used, giving a gradient nearly 1 miles long with an average severity of 1 in 12. With the gearbox in neutral a descent lasting 31 minutes was made first, with the foot brake lightly applied to restrict the speed to 20 m.p.h.

A " crash " stop from 20 m.p.h. gave a Tapley meter reading of 70 per cent., showing only 16 per cent. efficiency loss through fade. A second descent made after the hill climb caused a further reduction of only 21 per cent., by which time the drums were extremely hot. The system undoubtedly has excellent anti-fade properties and, together with the high power available, there should be no braking mishaps under any kind of operating condition.

The ascent of Reigate Hill took just under 54 minutes, during which time the ambient temperature was 43° F. The lowest gear required was second, with high auxiliary ratio engaged, and was used for 3f minutes. After starting the speed never fell below II m.p.h. and the engine pulled extremely well at low speed without any transmission roughness.

At the start of the climb the radiator temperature was 158° F. and the ascent caused a temperature rise of only 14° F., the radiator being two-thirds blanked. The more exacting part of the trial then followed—a day on the Army's proving ground at the F.V.R.D.E. having been booked. For these tests 21 tons had been tipped off the body to bring the gross weight down to 9 tons 11 cwt., this being the maker's rating for difficult cross-country operation.

For the first tests the Volvo was taken over the suspension courses, four runs down the 500-yd.-long pave strip being made initially. This pave is worse than anything normally experienced and is far more severe than the test course at the Motor Industry Research Association's ground at Lindley.

Over the pave it was possible to maintain a steady speed of 20 m.p.h. and, although the chassis was fiercely shaken about, the steering did not at any time become unmanageable. As an additional hazard the track was wet, but even this did not cause loss of control.

The 4x4 was then driven over the 11-in. setts, these being blocks of concrete transversely spaced at irregular intervals across the track, their distance apart varying between 1 ft. and 2 ft. Three runs were made over this course at about 30 m.p.h., and the steering at this speed was extraordinarily smooth. Only where the blocks were specially spaced did the chassis 'side-step," but even then it was possible to keep to a straight course by gentle correction on the steering wheel.

Further punishment was then delivered over the 21-in. setts. The two runs over this track would have loosened anything not really well assembled! For the most part there were rarely more than two wheels on the ground at any time, and at full throttle in third gear (high auxiliary) the speed remained at a shaky 20 m.p.h. The steering kicked viciously, as might be imagined, and the chassis kept jumping sideways over the bumps, although it was possible to correct this tendency.

At the end of these runs, totalling nearly three miles over shattering surfaces, a quick check of the Volvo showed the only damage to be a strained bonnet hinge. On three occasions the auxiliary box jumped out of mesh and the lever had to be held in engagement by one of my passengers, but the fault was found to be caused by an incorrectly adjusted linkage. Not even the spring U-bolts had loosened.

As a more restful test (certainly for driver and passengers) the Volvo was then taken up the test hills, where it surprised everyone by making a slow but confident climb up the 1 in 2 (261.°) incline in bottom gear, low auxiliary. The climb was made even more difficult by the slippery wooden slats which surface the slope, and only by running with one set of wheels on the concrete edging strips was traction maintained.

On the .1-in-4 and 1-in-3 test hills successful stop-start tests were carried oat, using bottom gear, low auxiliary, on each occasion. The 1-in-4 gradient was scaled non-stop in bottom gear with high auxiliary engaged, hut in this ratio the engine stalled on the 1-in-3 slope. These' restarts were repeated with equal success with the 'vehicle facing down the hills, and at no time did either the foot or hand brake give cause for alarm.

In the afternoon the vehicle was taken over the Alpine course, which is normally used by the Army for proving fully fledged military vehicles. Not once did its progress falter, whether it was driven up slippery 1-M-3 inclines, through hub-deep mud, over switchback surfaces at 25 m.p.h. (which, caused the wheels to lift clear of the ground), or through 18-in.-deep water-filled craters.

At all times there were sufficient power and adhesion and never did the steering become " too hot to hold." The suspension worked overtime during these tests, but surprisingly little of the loose load was lost and no damage was sustained by either the vehicle or its human cargo. A 'bad fault was that the tipping-ram brackets fouled the rear propeller shaft on several occasions.

Despite its ability to withstand rough treatment, the cab is in no way sparsely equipped, and driving along normal roads is a leisurely and comfortable occupation. On rough surfaces, however, a passenger grab-rail would be advantageous at times.

The driving seat is separate from the two-man passenger seat and it is adjustable vertically, longitudinally and 'transversely, whilst the squab and cushion are separately adjustable for tilt. A confusing point is that there are seven control levers in the cab, none of which is labelled and of which only the gearchange and hand-brake levers are obvious.

Cab insulation is particularly good, as befits a vehicle originating in chilly Sweden, and effectively deadens engine noise. This was further emphasized by the difficulty of hearing the horn in the cab, yet its note was strident to anyone outside.

, At the completion of the second day of road testing, and before the chassis became too dirty to handle, I carried out a few maintenance tests.

Spring-balanced Bonnet Hinges

To gain access to the power unit, the alligator-type bonnet, which has spring-balanced hinges, was raised in 6 seconds, after which the water level was checked in 14 seconds and the engine-oil level dipped in 19 seconds.

Level plugs are provided in the main and auxiliary gearboxes and a square key is included in the tool kit for removing them. The time taken to check these two levels was 53 seconds and 37.5 seconds, respectively. The same key tits the front and rear axle oil level plugs and these two levels were verified in 38.5 seconds and 32 seconds, respectively.

There is a single oil-bath air cleaner on the inlet_manifold and the level was checked in 32 seconds with the bonnet already raised. This filter was easy to reach as were the dual fuel filters. Each element in these filters was removed in 30 seconds, whilst replacement occupied a further 45 seconds, following which the complete fuel system was bled in 36 seconds.

Hydraulic non-adjustable tappets are found on several Volvo engines, but the D67A unit fitted to the 4 x 4 had adjustable tappets. There are twin rocker covers, each with two large securing bolts, and each cover took 40 seconds to remove, although to this time must be added 30 seconds for detaching the air cleaner. Replacing each cover occupied 25 seconds and the air cleaner was refitted in 50 seconds.

Two 12v. batteries are housed in a crate on the right of the chassis frame immediately behind the cab. This crate has a substantial steel cover, which is secured by two wing nuts, and it was possible to remove the cover, check the levels and refit the cover in 1+ minutes.

Spare Wheel Winch Useful

As a final check, I removed the spare wheel and replaced it. The wheel is clamped to a carrier by four nuts, and with these loosened the wheel may then be lowered to the ground by means of a winch which has a

ratchet stop on it. To remove the clamping nuts required 2.4 minutes and to lower the wheel to the ground, 15 seconds.

In the reverse way,. I took only 30 seconds to raise the wheel on to its locating studs and a further 21 minutes to replace and tighten the nuts.

The Volvo L38545 chassis, complete with NystrOm cab, has a basic price in Great Britain of £2,905, plus approximately £668 purchase tax. The Air-Pak servo costs an extra £100, whilst the winch adds a further £200 to the price_ The sterling export price of the chassis, however, is lower, being only £2,350, with no purchase tax payable.